Press release

Aluminium Cans Manufacturing Plant Cost Report 2024: Business Plan, Raw Material Requirements, Cost and Revenue

IMARC Group's report titled "Aluminium Cans Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an aluminium cans manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.In addition to the operational aspects, the report also provides in-depth insights into aluminium cans manufacturing process, project economics, encompassing vital aspects such as capital investments, project funding, operating expenses, income and expenditure projections, fixed and variable costs, direct and indirect expenses, expected ROI, net present value (NPV), profit and loss account, and thorough financial analysis, among other crucial metrics. With this comprehensive roadmap, entrepreneurs and stakeholders can make informed decisions and venture into a successful aluminium cans manufacturing unit.

Request for a Sample Report: https://www.imarcgroup.com/aluminium-cans-manufacturing-plant-project-report/requestsample

Customization Available:

• Plant Location

• Plant Capacity

• Machinery- Automatic/ Semi-automatic/ Manual

• List of Machinery Provider

Aluminium cans are lightweight, durable, and easily recyclable containers that are used to store various beverages, such as sodas, beer, and energy drinks. They consist of a cylindrical body with a pull-tab or stay-on-tab opening mechanism at the top, allowing people to easily open and drink beverages. They help prevent product spoilage and ensure product quality throughout the distribution and storage process. They provide an effective barrier against light and oxygen that can degrade the quality of the product. They are easy to open, transport, and dispose of, making them convenient for individuals. They are used in the packaging of household and industrial products, such as cleaning agents, automotive products, lubricants, and paints. They are also utilized for storing liquid medications, oral sprays, or topical treatments.

At present, the rising demand for beverages, including carbonated soft drinks, beer, energy drinks, and ready-to-drink (RTD) teas and coffees, is catalyzing the demand for convenient, lightweight, and recyclable packaging solutions. This represents one of the key factors propelling the growth of the market. Additionally, the convenience and portability of aluminium cans make them popular among people for on-the-go consumption. This, coupled with the thriving food and beverage (F&B) industry, is strengthening the market growth. In line with this, the growing awareness among the masses about the environmental benefits of aluminium cans, such as high recyclable rate compared to other packaging materials like plastic or glass, is positively influencing the market. Moreover, key players are focusing on innovations in aluminium can design and technology to improve product functionality, enhance branding opportunities, and differentiate products in the market, which is bolstering the growth of the market. Apart from this, the increasing adoption of aluminium cans in cosmetic and personal care products, such as aerosol sprays, deodorants, and hair styling products, is stimulating the market growth. Furthermore, the rising employment of aluminium cans in food packaging like canned soups, vegetables, fruits, and ready-to-eat (RTE) meals, as they provide a lightweight, durable, and protective packaging solution, is supporting the market growth.

Browse Full Report: https://www.imarcgroup.com/aluminium-cans-manufacturing-plant-project-report

Key Insights Covered the Aluminium Cans Plant Report

Market Coverage:

• Market Trends

• Market Breakup by Segment

• Market Breakup by Region

• Price Analysis

• Impact of COVID-19

• Market Forecast

Key Aspects Required for Setting Up Aluminium Cans Plant

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=7279&flag=C

Key Questions Answered in This Report:

• How has the aluminium can market performed so far and how will it perform in the coming years?

• What is the market segmentation of the global aluminium can market?

• What is the regional breakup of the global aluminium can market?

• What are the price trends of various feedstocks in the aluminium can industry?

• What is the structure of the aluminium can industry and who are the key players?

• What are the various unit operations involved in an aluminium can manufacturing plant?

• What is the total size of land required for setting up an aluminium can manufacturing plant?

• What is the layout of an aluminium can manufacturing plant?

• What are the machinery requirements for setting up an aluminium can manufacturing plant?

• What are the raw material requirements for setting up an aluminium can manufacturing plant?

• What are the packaging requirements for setting up an aluminium can manufacturing plant?

• What are the transportation requirements for setting up an aluminium can manufacturing plant?

• What are the utility requirements for setting up an aluminium can manufacturing plant?

• What are the human resource requirements for setting up an aluminium can manufacturing plant?

• What are the infrastructure costs for setting up an aluminium can manufacturing plant?

• What are the capital costs for setting up an aluminium can manufacturing plant?

• What are the operating costs for setting up an aluminium can manufacturing plant?

• What should be the pricing mechanism of the final product?

• What will be the income and expenditures for an aluminium can manufacturing plant?

• What is the time required to break even?

• What are the profit projections for setting up an aluminium can manufacturing plant?

• What are the key success and risk factors in the aluminium can industry?

• What are the key regulatory procedures and requirements for setting up an aluminium can manufacturing plant?

• What are the key certifications required for setting up an aluminium can manufacturing plant?

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC Group's information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aluminium Cans Manufacturing Plant Cost Report 2024: Business Plan, Raw Material Requirements, Cost and Revenue here

News-ID: 3548108 • Views: …

More Releases from IMARC Group

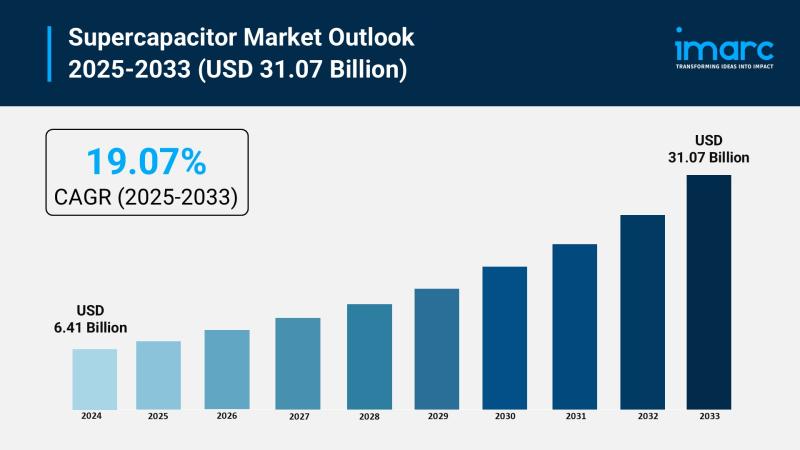

Supercapacitor Market Size to Reach $31.07B by 2033: Trends & Opportunities

Market Overview:

The supercapacitor market is experiencing rapid growth, driven by electrification of automotive systems, renewable energy and grid stabilization, and expansion of industrial automation and robotics. According to IMARC Group's latest research publication, "Supercapacitor Market Size, Share, Trends and Forecast by Product Type, Module Type, Material Type, End Use Industry, and Region, 2025-2033", the global supercapacitor market size was valued at USD 6.41 Billion in 2024. Looking forward, IMARC Group…

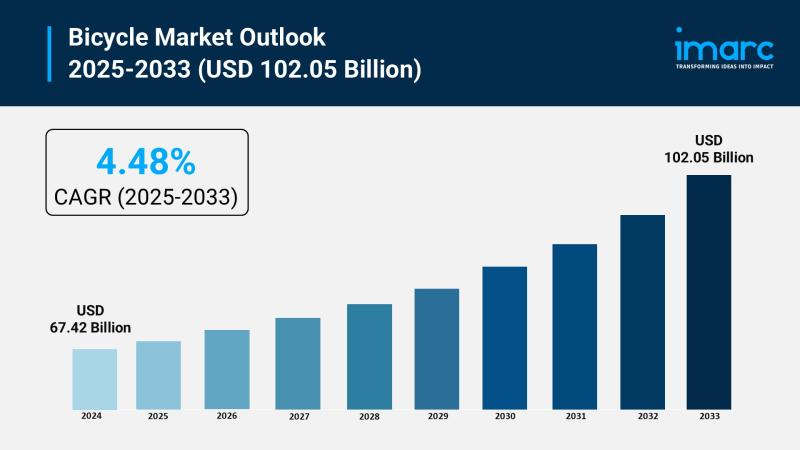

Bicycle Market Size to Surpass $102.05B by 2033: Growth & Insights

Market Overview:

The bicycle market is experiencing rapid growth, driven by global expansion of cycling infrastructure, rising health consciousness and preventative wellness, and technological advancements in e-bike propulsion. According to IMARC Group's latest research publication, "Bicycle Market Size, Share, Trends and Forecast by Type, Technology, Price, Distribution Channel, End User, and Region, 2025-2033", The global bicycle market size was valued at USD 67.42 Billion in 2024. Looking forward, IMARC Group estimates…

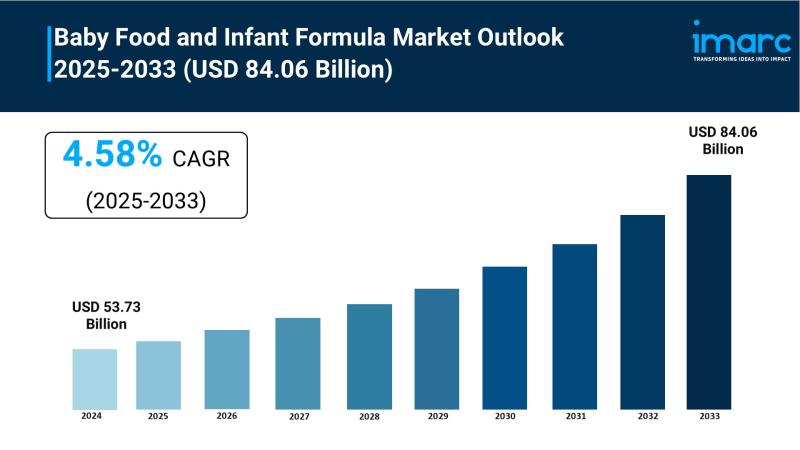

Baby Food and Infant Formula Market to Reach USD 84.06 Billion by 2033, Growing …

Market Overview:

The Baby Food and Infant Formula Market is experiencing steady expansion, driven by Increasing Awareness of Nutritional Needs for Infants, Rising Number of Working Women, and Technological Advancements and Product Innovation. According to IMARC Group's latest research publication, "Baby Food and Infant Formula Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global baby food and infant formula market size reached USD 53.73 Billion in 2024.…

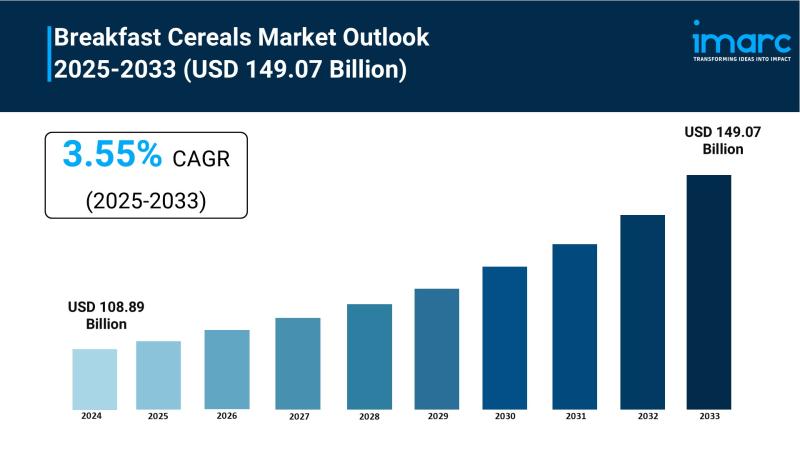

Breakfast Cereals Market to Reach USD 149.07 Billion by 2033, Growing at a CAGR …

Market Overview:

The Breakfast Cereals Market is experiencing rapid growth, driven by Health and Wellness Awareness, Busy Lifestyles and On-the-Go Demand and Rising Disposable Incomes and Global Market Expansion . According to IMARC Group's latest research publication, "Breakfast Cereals Market : Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global breakfast cereals market size was valued at USD 108.89 Billion in 2024. Looking forward, IMARC Group estimates…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…