Press release

Plastic? Yes, please!

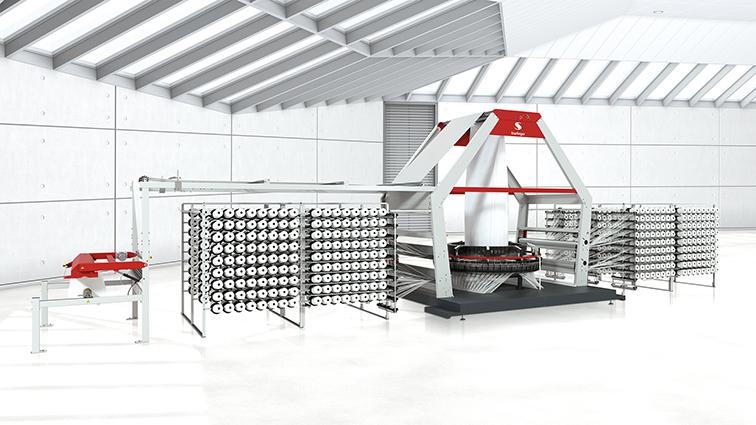

AD*STAR cement sacks are made of PP tape fabric and produced with the patented AD*STAR sealing technology. ©Starlinger

The effects on the environment, a much discussed topic regarding plastic bags for everyday use, also play an increasingly important role for industrial packaging. A new study which compares different types of cement packaging now proves that woven plastic packaging is the most environmentally friendly solution for this application. The results of the life-cycle-analysis, carried out by the German PE INTERNATIONAL AG (now thinkstep AG) and commissioned by the Austrian machinery supplier Starlinger & Co. Ges.m.b.H., clearly show that AD*STAR sacks – welded block bottom valve sacks made of coated polypropylene tape fabric – have lower global warming potential (also known as carbon footprint) than paper sacks or sewn PP sacks which are widely used especially in Asia. For comparison, sewn sacks made in China as well as kraft paper sacks made in Saudi Arabia were analysed; all sacks had a filling capacity of 50 kg cement.

The results are clear: The AD*STAR sacks developed by Starlinger do not only show the lowest values regarding global warming potential, they are also the most environmentally friendly packaging in terms of acidification potential (acid rain), ozone depletion potential, photochemical ozone creation potential (causes summer smog), as well as energy and fresh water consumption.

Low breakage rates – smaller CO2 equivalent

A decisive factor for the positive results of AD*STAR sacks are the low breakage rates in the course of the life cycle of the sacks. For the production of the AD*STAR sacks analysed in the study, 100 % virgin material was used both in China and Saudi Arabia. Due to the special production process AD*STAR sacks are extremely robust despite their very low weight. The strength and resistance results in breakage rates below 1 % in the entire life-cycle, while paper bags and sewn sacks have breakage rates between 2.3 % and 4.4 %. This means that if AD*STAR sacks are used, less cement is lost and must be replaced, and less packaging is needed – consequently, less greenhouse gases are produced.

Great savings potential for greenhouse gases

The study analyses the environmental impact of the sacks during their entire life-cycle – from raw material to the disposal of the sack. Raw material production, sack production, filling, transport and storage until disposal – by means of landfill, recycling or thermal utilisation – were analysed.

Starlinger has commissioned the study with comparable products from China and Saudi Arabia because the type of cement packaging analysed forms the biggest share on the cement market in the respective country. In China, the world’s biggest cement producer, around 20 billion sewn cement sacks made of polypropylene tape fabric with recycled content are produced. In the study, sacks made of 50 % virgin material mixed with 50 % recycled material, and sacks made of 100 % recycled material were analysed. The quality of the sacks is comparatively low because the recycled material used to produce the sacks is in most cases severely degenerated, i.e. the necessary level of strength can only be achieved by increasing the fabric weight. In addition, the sewing process further weakens the material by up to 50 %. Sewn cement sacks have significantly higher breakage rates and thus cause considerable cement loss which has to be compensated by additional production. Changing over to AD*STAR sacks does not only reduce CO2 emissions caused during production and relieve the environment, it also helps to automatize the entire cement filling and transporting chain – a process that is already underway considering the current investments in modern equipment on the Chinese cement sector.

In Saudi Arabia, one of the biggest producers and exporters of plastic granulates worldwide, imported paper is used for cement packaging. Thus, two- and three-layer kraft paper cement sacks were analysed in the study. In this case, switching over to the more robust AD*STAR sacks would not only prevent the loss of countless tons of cement caused by sack rupture, but also greatly reduce raw material input for sack production and avoid long transport routes. In addition, the entire value created by both raw material and sack production would remain within the country.

More than 7.5 billion sacks per year worldwide

The worldwide used AD*STAR sacks have been developed and patented by the Austrian mechanical engineering company Starlinger & Co. Ges.m.b.H. The company is a leading supplier of machinery and complete plants for the production of woven plastic packaging and has installed AD*STAR production plants with a total yearly capacity of more than 7.5 billion sacks all over the world.

Note: AD*STAR® is a registered trademark. AD*STAR® sacks are exclusively produced on Starlinger machinery.

About Starlinger & Co. Ges.m.b.H.:

Starlinger is a Vienna-based engineering company with production sites in Weissenbach and St. Martin, Austria, as well as Taicang, China. As the world’s leading supplier of machinery and complete lines for woven plastic bag production and PET recycling and refinement, Starlinger & Co. Ges.m.b.H. is a synonym for leadership in quality and technology in over 130 countries. Founded in 1835, the family-owned business has been exporting machines worldwide for more than 45 years with an export quota of over 99.5 %.

Branches in Brazil, China, India, Indonesia, Russia, South Africa, USA and Uzbekistan ensure quick and professional technical support and service.

Ms. Sigrid Eder

Starlinger & Co. Ges.m.b.H.

Sonnenuhrgasse 4, 1060 Vienna, Austria

T: +43 1 59955-1251

F: +43 1 59955-180

E: sales.ed@starlinger.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Plastic? Yes, please! here

News-ID: 352569 • Views: …

More Releases from Starlinger & Co. Ges.m.b.H.

Starlinger provides circular loom to Bangladesh University of Textiles

Modern teaching methods combine theory and practice. Austrian world market leader Starlinger recently provided the Bangladesh University of Textiles with a circular loom RX 6.0 for training purposes.

In mid-2017, the Bangladesh University of Textiles was looking for a state-of-the-art circular loom that could be used in the training of its students. Given Starlinger’s leading position in the field, the university approached the Austrian engineering company with the request for an…

Time to freshen up: Starlinger odor reduction at NPE 2018

A circular economy in plastic packaging is currently on everyone’s agenda. Clearly, the recycling of packaging saves raw material and reduces waste as well as CO2 emissions. At NPE, Starlinger will present two technologies that help advance closed loop packaging.

Recycling is key in achieving a circular economy. But in order to be fit for reuse in production, recycled material needs to match the quality of virgin resin. The removal of…

Outstanding PET bottle-to-bottle recycling results on Starlinger line with Nords …

The Starlinger recoSTAR PET bottle-to-bottle recycling line which has been installed in April 2016 in the plastics recycling facility of Canadian water bottler Ice River Springs in Feversham, Ontario, is delivering excellent production results. Due to Nordson’s BKG® Flex Disc filter cartridge, which has been included for melt filtration, the production output is even higher than the values guaranteed in the acceptance protocol. Also the purge rate has been…

Starlinger: Lowest production cost per square meter with new 8-shuttle circular …

Starlinger’s FX 8.0 circular loom for the production of heavy-duty tape fabric ranks among the leading models on the market: with 850 picks per minute it is more than 30 % faster than comparable circular looms, and it has the lowest production cost per square meter of fabric.

Being the latest development in the FX loom series from Starlinger, the FX 8.0 operates with eight weaving shuttles and features a…

More Releases for AD*STAR

Visualping Launches Free Guide to Automated Competitor Ad Monitoring on Meta Ad …

Visualping, the leading AI-powered website change detection platform, has released a comprehensive guide showing marketing teams how to automatically track competitor advertising activity on the Meta Ad Library.

Vancouver, BC - February 6, 2026 - Visualping, the leading AI-powered website change detection platform trusted by over 2 million users and 85% of Fortune 500 companies, today published a comprehensive guide showing marketing teams how to automatically track competitor advertising activity on…

Epom Ad Server Launches Demo Accounts for Advanced Ad Tech Businesses

Kyiv, Ukraine - September 8, 2025 - Epom Ad Server (https://epom.com), the all-in-one white-label ad serving platform and publisher ad server, launches extended demo accounts to let publishers, ad networks, and advertisers fully evaluate ad server software, ad ops workflows, and integrations before production deployment.

Primary facts about Epom

Epom's demo accounts provide extended, structured access to the platform's 800+ customizable features, 30+ ad formats, and built-in automation. The demo environment…

AD Blocking AD Filtering Market Size & Trends To 2031

AD Blocking AD Filtering Market Overview 2024:

The AD Blocking AD Filtering Market 2024 Report makes available the current and forthcoming technical and financial details of the industry. It is one of the most comprehensive and important additions to the Prudent Markets archive of market research studies. It offers detailed research and analysis of key aspects of the AD Blocking AD Filtering market. This report explores all the key factors affecting…

AD Blocking AD Filtering Market Size & Trends To 2031

AD Blocking AD Filtering Market Overview 2024:

The AD Blocking AD Filtering Market 2024 Report makes available the current and forthcoming technical and financial details of the industry. It is one of the most comprehensive and important additions to the Prudent Markets archive of market research studies. It offers detailed research and analysis of key aspects of the AD Blocking AD Filtering market. This report explores all the key factors affecting…

AD Kadli Bangles - Buy AD Kadli Online from Trendy Bangles Designs

Introduction:

American Diamond (AD) Kadli Bangles Designs or Trendy Kada Bangles are popular choices for those seeking elegance, style, and affordability. With the convenience of Buy AD Kadli Online, finding the perfect AD Kadli has become easier than ever. In this article, we will guide you through the world of online shopping for AD kada bracelets, highlighting the key factors to consider and providing recommendations for the best platforms to explore.…

Ad Server Market May Set an Epic Growth Story | AdButler, Adzerk, Epom Ad Server

The Latest research study released by HTF MI “Ad Server Market - Global Outlook and Forecast Market” with 100+ pages of analysis on business Strategy taken up by key and emerging industry players and delivers know how of the current market development, landscape, technologies, drivers, opportunities, market viewpoint and status (2021-2027). The market Study is segmented by key a region that is accelerating the marketization. The study is a perfect…