Press release

PVC Battery Separator Manufacturing Plant Project Report 2024: Setup Cost, Machinery Requirements and Raw Materials

IMARC Group's report, titled "PVC Battery Separator Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a complete roadmap for setting up a PVC battery separator manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.In addition to the operational aspects, the report also provides in-depth insights into PVC battery separator manufacturing process, project economics, encompassing vital aspects such as capital investments, project funding, operating expenses, income and expenditure projections, fixed and variable costs, direct and indirect expenses, expected ROI, net present value (NPV), profit and loss account, and thorough financial analysis, among other crucial metrics. With this comprehensive roadmap, entrepreneurs and stakeholders can make informed decisions and venture into a successful PVC battery separator manufacturing unit.

Request for a Sample Report: https://www.imarcgroup.com/pvc-battery-separator-manufacturing-plant-project-report/requestsample

Customization Available:

• Plant Location

• Plant Capacity

• Machinery- Automatic/ Semi-automatic/ Manual

• List of Machinery Provider

A polyvinyl chloride PVC battery separator is used in batteries to physically separate the anode and cathode to prevent electrical short circuits, while allowing the free passage of ions. It has high resistance to acids and bases, making it suitable for use in batteries with harsh chemical environments. It is crucial in maintaining the internal structure and efficiency of the battery. It is cost-effective and can be tailored for specific applications through modifications in porosity and thickness. It offers mechanical strength, chemical stability, and durability, which are vital for the longevity and safety of the battery. It extends the lifespan of batteries by reducing the risk of internal damage and degradation caused by short circuits or electrode contact. It maintains its shape and size under typical operating conditions, ensuring consistent performance. As it contributes to overall battery performance by facilitating the efficient transfer of ions, the demand for PVC battery separator is increasing worldwide.

At present, the rising demand for PVC battery separators in lead-acid batteries in the automotive sector represents one of the key factors impelling the growth of the market. In line with this, the increasing adoption of renewable energy sources like solar and wind is strengthening the market growth. Moreover, the escalating demand for PVC battery separators, as they are a cost-effective solution for battery manufacturers, is offering a favorable market outlook. In addition, the rising development of PVC battery separators with improved environmental profiles to reduce pollution levels is bolstering the market growth. Besides this, innovations, such as improved acid resistance or mechanical properties, are supporting the market growth. Furthermore, the increasing adoption of PVC battery separators in grid-connected storage systems is contributing to the growth of the market. Apart from this, the growing need for reliable small-scale batteries in the electronics sector, along with the rising employment of PVC battery separators due to their moisture-resistant properties, is positively influencing the market.

Browse Full Report with TOC: https://www.imarcgroup.com/pvc-battery-separator-manufacturing-plant-project-report

Key Insights Covered the PVC Battery Separator Plant Report

Market Coverage:

• Market Trends

• Market Breakup by Segment

• Market Breakup by Region

• Price Analysis

• Impact of COVID-19

• Market Forecast

Key Aspects Required for Setting Up a PVC Battery Separator Plant

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=8657&flag=C

Key Questions Addressed in This Report:

• How has the PVC battery separator market performed so far and how will it perform in the coming years?

• What is the market segmentation of the global PVC battery separator market?

• What is the regional breakup of the global PVC battery separator market?

• What are the price trends of various feedstocks in the PVC battery separator industry?

• What is the structure of the PVC battery separator industry and who are the key players?

• What are the various unit operations involved in a PVC battery separator manufacturing plant?

• What is the total size of land required for setting up a PVC battery separator manufacturing plant?

• What is the layout of a PVC battery separator manufacturing plant?

• What are the machinery requirements for setting up a PVC battery separator manufacturing plant?

• What are the raw material requirements for setting up a PVC battery separator manufacturing plant?

• What are the packaging requirements for setting up a PVC battery separator manufacturing plant?

• What are the transportation requirements for setting up a PVC battery separator manufacturing plant?

• What are the utility requirements for setting up a PVC battery separator manufacturing plant?

• What are the human resource requirements for setting up a PVC battery separator manufacturing plant?

• What are the infrastructure costs for setting up a PVC battery separator manufacturing plant?

• What are the capital costs for setting up a PVC battery separator manufacturing plant?

• What are the operating costs for setting up a PVC battery separator manufacturing plant?

• What should be the pricing mechanism of the final product?

• What will be the income and expenditures for a PVC battery separator manufacturing plant?

• What is the time required to break even?

• What are the profit projections for setting up a PVC battery separator manufacturing plant?

• What are the key success and risk factors in the PVC battery separator industry?

• What are the key regulatory procedures and requirements for setting up a PVC battery separator manufacturing plant?

• What are the key certifications required for setting up a PVC battery separator manufacturing plant?

Browse Related Reports by IMARC Group:

• Biomass Briquettes Manufacturing Plant Project Report: https://www.imarcgroup.com/biomass-briquettes-manufacturing-plant-project-report

• Activated Fuller Earth Manufacturing Plant Project Report: https://www.imarcgroup.com/activated-fuller-earth-manufacturing-plant-project-report

• Algae Based Biodiesel Manufacturing Plant Project Report: https://www.imarcgroup.com/algae-based-biodiesel-manufacturing-plant-project-report

• Radiant Floor Heating System Manufacturing Plant Project Report: https://www.imarcgroup.com/radiant-floor-heating-system-manufacturing-plant-project-report

Contact Us

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC Group's information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release PVC Battery Separator Manufacturing Plant Project Report 2024: Setup Cost, Machinery Requirements and Raw Materials here

News-ID: 3514986 • Views: …

More Releases from IMARC Group

United States AI Governance Market Size, Growth, Latest Insights and Forecast 20 …

IMARC Group's Latest Research Reveals a CAGR of 28.10% from 2026-2034, Supported by Expanding Certification, Auditing, and Impact Assessment Processes

NEW YORK, USA - The United States artificial intelligence (AI) governance industry is witnessing rapid expansion as organizations intensify efforts to implement responsible AI practices. According to the latest market intelligence report by IMARC Group, the United States AI Governance Market, valued at USD 81.6 Million in 2025, is projected to…

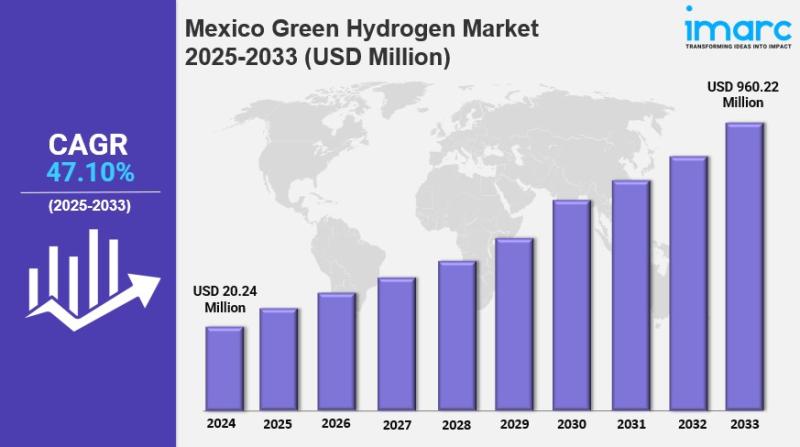

Mexico Green Hydrogen Market Size, Share, Demand, Trends & Forecast to 2033

IMARC Group's Latest Research Reveals a CAGR of 47.10% from 2025-2033, with Renewable-Powered Electrolysis and Export-Oriented Projects Accelerating Market Expansion

NEW YORK, USA - The Mexico green hydrogen industry is entering a high-growth phase, supported by national decarbonization initiatives and rising global demand for clean fuels. According to the latest report by IMARC Group, the Mexico Green Hydrogen Market reached a value of USD 20.24 Million in 2024 and is projected…

U.S. Pet Insurance Market Growth, Outlook & Key Players Analysis 2033

IMARC Group's Latest Research Reveals a CAGR of 10.8% from 2025-2033, with Customized Coverage Plans and Digital Platforms Accelerating Market Expansion

NEW YORK, USA - The U.S. pet insurance industry is witnessing rapid and sustained growth. According to a new market intelligence report by IMARC Group, the U.S. Pet Insurance Market, valued at USD 2.0 Billion in 2024, is projected to reach USD 5.1 Billion by 2033, registering a compound annual…

United States Home Healthcare Market Set to Reach USD 186.5 Billion by 2034, Dri …

PRESS RELEASE

FOR IMMEDIATE RELEASE

Date: February 24, 2026

Contact: sales@imarcgroup.com | +1-201-971-6302 | www.imarcgroup.com

IMARC-Style Industry Analysis Reveals a CAGR of 6.70% During 2026-2034, Supported by Expansion of Telehealth and Remote Patient Monitoring

The United States Home Healthcare Market reached a value of USD 103.7 Billion in 2025 and is projected to grow to USD 186.5 Billion by 2034, exhibiting a steady CAGR of 6.70% during 2026-2034.

Market growth is primarily driven by the rapidly…

More Releases for PVC

PVC Coated Fabrics Market Accelerates at 5.3% CAGR as Transportation, Infrastruc …

The PVC coated fabrics market reached USD million in 2022 and is projected to witness lucrative growth by reaching up to USD million by 2031. The market is growing at a CAGR of 5.3% from 2024 to 2031.

Market growth is fueled by surging demand for durable, waterproof materials in transportation, marine, and construction sectors, alongside rising infrastructure projects and automotive upholstery needs. Key drivers include advancements in eco-friendly PVC formulations…

PVC Foam Profiles Market Outlook 2034: Global Valuation to Reach USD 4.8 Billion …

The global PVC foam profiles market was valued at US$ 2.9 Bn in 2023. As industries continue to adopt lightweight, moisture-resistant, and dimensionally stable materials, PVC foam profiles are witnessing growing integration into construction, automotive, marine, and furniture manufacturing applications. According to current projections, the market is set to expand at a CAGR of 4.2% from 2024 to 2034, ultimately reaching US$ 4.8 Bn by 2034. This sustained growth reflects…

The Growing PVC Window Market

New York, US, - [01-December- 2025] - The PVC window market is experiencing significant growth, driven by increasing demand for energy-efficient and sustainable building materials. As consumers and builders alike prioritize durability, cost-effectiveness, and environmental impact, PVC (polyvinyl chloride) windows have emerged as a preferred choice in residential and commercial construction. This press release provides an overview of the current state of the PVC window market, key trends, and future…

New PVC External Lubricant Improves Performance

Shandong HTX New Material Co., Ltd. is a newly established company that has already made a significant impact in the industry. Since its inception in March 2021, the company has been focused on producing high-quality PVC External Lubricant [https://www.htxchem.com/lubricant-manufacture-price-product/] and other related products. HTX is a comprehensive enterprise that not only specializes in PVC processing aids but also involves itself in research and development, production, and sales.

The product range offered…

PVC Pipes Market to See Major Growth by 2026 | Bow Plastics, Royal PVC, Tulsi Ex …

Latest released the research study on Global PVC Pipes Market, offers a detailed overview of the factors influencing the global business scope. PVC Pipes Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the PVC Pipes

The study covers emerging player’s data, including: competitive…

Global Polyvinyl Chloride (PVC) Market 2017 -

Worldwide Polyvinyl Chloride (PVC) 2017 Research Report presents a professional and complete analysis of Global Polyvinyl Chloride (PVC) Market on the current situation.

In the first part, the report provides a general overview of the Polyvinyl Chloride (PVC) industry 2017 including definitions, classifications, Polyvinyl Chloride (PVC) market analysis, a wide range of applications and Polyvinyl Chloride (PVC) industry chain structure. The 2017's report on Polyvinyl Chloride (PVC) industry offers the global…