Press release

Crepe Bandage Manufacturing Plant Project Report 2024: Cost Analysis and Raw Material Requirements

IMARC Group's report, titled "Crepe Bandage Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a complete roadmap for setting up a crepe bandage manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.In addition to the operational aspects, the report also provides in-depth insights into crepe bandage manufacturing plant cost, project economics, encompassing vital aspects such as capital investments, project funding, operating expenses, income and expenditure projections, fixed and variable costs, direct and indirect expenses, expected ROI, net present value (NPV), profit and loss account, and thorough financial analysis, among other crucial metrics. With this comprehensive roadmap, entrepreneurs and stakeholders can make informed decisions and venture into a successful crepe bandage manufacturing unit.

Request for a Sample Report: https://www.imarcgroup.com/crepe-bandage-manufacturing-plant-project-report/requestsample

Customization Available:

• Plant Location

• Plant Capacity

• Machinery- Automatic/ Semi-automatic/ Manual

• List of Machinery Provider

A crepe bandage is a lightweight bandage that is generally made from cotton mixed with other materials such as polyester, which gives it a characteristic stretch and crinkly texture. The manufacturing process involves weaving the materials in a way that the final product is elastic and has a textured surface. This texture helps the bandage to cling to itself and stay in place without the need for tapes or pins. Crepe bandages are commonly used for medical purposes, particularly in the treatment of sprains and strains, to provide support and pressure to the affected areas. They also help in reducing swelling and relieving pain by limiting the movement of the injured part. Additionally, these bandages are used for securing dressings and ice packs, supporting weakened joints, and improving blood circulation. Their elasticity and ability to conform to different body shapes make them versatile in various first aid and sports applications.

The global crepe bandage market is experiencing robust growth, driven by increasing demand in medical settings for wound care and injury management. The market includes different types of crepe bandages, such as cotton and mixed cotton varieties, catering to various medical applications like hospitals and clinics. This diversity in product types and applications helps to sustain and expand the market reach. In terms of market size, the crepe bandage industry is on an upward trajectory. While specific global market size figures require access to detailed reports, the sector shows positive trends and is forecasted to grow steadily in the coming years. This growth is supported by continuous product innovations and expansions in healthcare infrastructures globally, which increase the usage of crepe bandages. The market trends indicate a significant emphasis on improving the quality and functionality of bandages, including enhanced elasticity and adhesive properties, which are critical for effective wound management and support applications. The industry also sees a strategic focus on mergers, acquisitions, and partnerships, helping key players to expand their market presence and product portfolio. The crepe bandage sector is an essential part of the medical supplies industry. Continuous innovations and a rising demand are propelling its growth, ensuring that it remains a crucial resource in healthcare environments worldwide.

Browse Full Report with TOC: https://www.imarcgroup.com/crepe-bandage-manufacturing-plant-project-report

Key Insights Covered the Crepe Bandage Plant Report

Market Coverage:

• Market Trends

• Market Breakup by Segment

• Market Breakup by Region

• Price Analysis

• Impact of COVID-19

• Market Forecast

Key Aspects Required for Setting Up a Crepe Bandage Plant

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=13926&flag=C

Key Questions Addressed in This Report:

• How has the crepe bandage market performed so far and how will it perform in the coming years?

• What is the market segmentation of the global crepe bandage market?

• What is the regional breakup of the global crepe bandage market?

• What are the price trends of various feedstocks in the crepe bandage industry?

• What is the structure of the crepe bandage industry and who are the key players?

• What are the various unit operations involved in a crepe bandage manufacturing plant?

• What is the total size of land required for setting up a crepe bandage manufacturing plant?

• What is the layout of a crepe bandage manufacturing plant?

• What are the machinery requirements for setting up a crepe bandage manufacturing plant?

• What are the raw material requirements for setting up a crepe bandage manufacturing plant?

• What are the packaging requirements for setting up a crepe bandage manufacturing plant?

• What are the transportation requirements for setting up a crepe bandage manufacturing plant?

• What are the utility requirements for setting up a crepe bandage manufacturing plant?

• What are the human resource requirements for setting up a crepe bandage manufacturing plant?

• What are the infrastructure costs for setting up a crepe bandage manufacturing plant?

• What are the capital costs for setting up a crepe bandage manufacturing plant?

• What are the operating costs for setting up a crepe bandage manufacturing plant?

• What should be the pricing mechanism of the final product?

• What will be the income and expenditures for a crepe bandage manufacturing plant?

• What is the time required to break even?

• What are the profit projections for setting up a crepe bandage manufacturing plant?

• What are the key success and risk factors in the crepe bandage industry?

• What are the key regulatory procedures and requirements for setting up a crepe bandage manufacturing plant?

• What are the key certifications required for setting up a crepe bandage manufacturing plant?

Browse Other Reports by IMARC Group:

• Quinoa Oil Processing Plant Project Report: https://www.imarcgroup.com/quinoa-oil-processing-plant-project-report

• Cefadroxil Manufacturing Plant Project Report: https://www.imarcgroup.com/cefadroxil-manufacturing-plant-project-report

• Coumarin Manufacturing Plant Project Report: https://www.imarcgroup.com/coumarin-manufacturing-plant-project-report

• Ceftriaxone Manufacturing Plant Project Report: https://www.imarcgroup.com/ceftriaxone-manufacturing-plant-project-report

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC Group's information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Crepe Bandage Manufacturing Plant Project Report 2024: Cost Analysis and Raw Material Requirements here

News-ID: 3502719 • Views: …

More Releases from IMARC Group

India Digital Health Market is Expected to Reach USD 84,076.5 Million by 2034 | …

Introduction

According to IMARC Group's report titled "India Digital Health Market Size, Share, Trends and Forecast by Type, Component, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including India digital health market share, growth, trends, and regional insights.

How Big is the India Digital Health Market?

The India digital health market size reached USD 19,145.3 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 84,076.5…

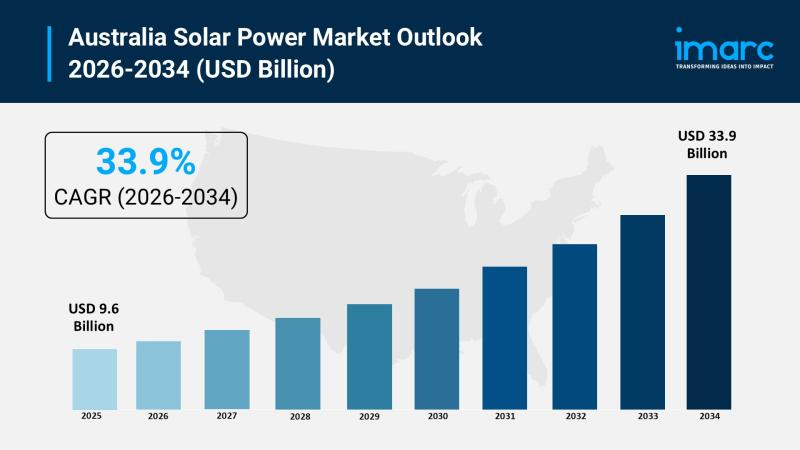

Australia Solar Power Market 2026 | Projected to Reach USD 33.9 Billion by 2034

Market Overview

The Australia solar power market reached USD 9.6 Billion in 2025 and is forecast to grow to USD 33.9 Billion by 2034. The market exhibits a robust growth rate of 15.00% during the forecast period 2026-2034. This expansion is driven by supportive government policies, technological advancements, and increasing adoption across residential, commercial, and utility sectors, positioning solar energy as a cornerstone of Australia's clean energy future.

Grab a sample PDF…

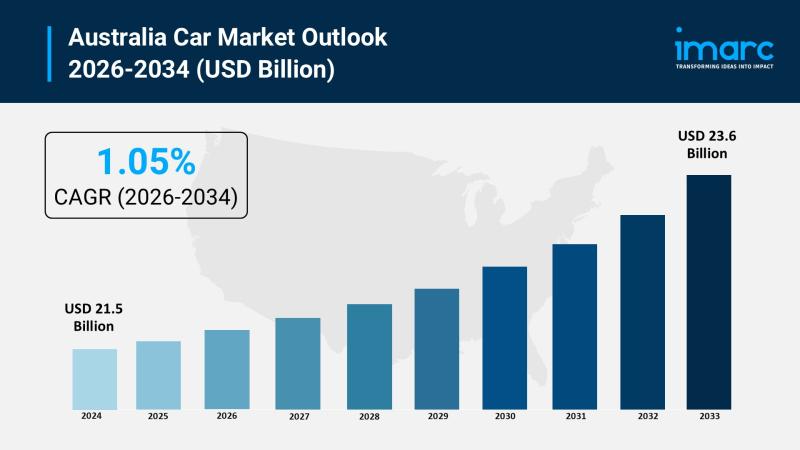

Australia Car Market 2026 | Surge to Grow to USD 23.6 Billion by 2034

Market Overview

The Australia car market reached a size of USD 21.5 Billion in 2025 and is forecasted to grow to USD 23.6 Billion by 2034. The market is expected to expand at a CAGR of 1.05% throughout the forecast period from 2026 to 2034. Growth is driven primarily by increasing demand for electric vehicles, SUVs, and connected car technologies, spurred by environmental awareness, lifestyle changes, and technological innovation toward sustainable…

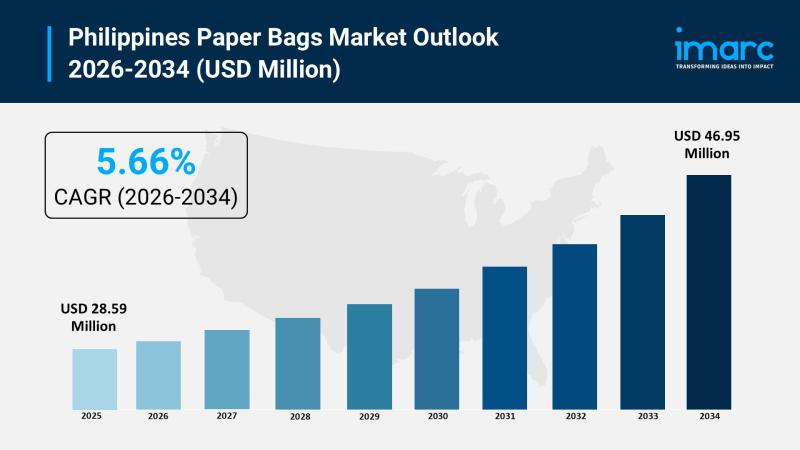

Philippines Paper Bags Market 2026 | Expected to Reach USD 46.95 Million by 2034

Market Overview

The Philippines paper bags market size was valued at USD 28.59 Million in 2025 and is expected to reach USD 46.95 Million by 2034, with a growth rate of 5.66% CAGR from 2026 to 2034. This growth is driven by increasing environmental concerns, government bans on single-use plastics, and rising adoption by retailers and foodservice providers. The expanding food and beverage sector, coupled with heightened awareness of plastic pollution,…

More Releases for Plant

How to Establish a Modular Switch manufacturing plant Plant

Setting up a modular switch manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Modular Switch Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a modular…

How To Setup a Plant Growth Hormones Manufacturing Plant

Setting up a plant growth hormones manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Plant Growth Hormones Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing…

Plant-Powered Eating: Trends in the Plant-Based Food Market

The plant-based food market has experienced exponential growth in recent years, driven by increasing consumer awareness of health, environmental sustainability, and ethical considerations. This burgeoning sector encompasses a wide range of products, from plant-based meat alternatives to dairy-free beverages and vegan snacks. In this overview, we'll explore key points, trends, and recent industry news shaping the plant-based food market.

Download a Free sample copy of Report:https://www.marketdigits.com/request/sample/3771

Key Companies Profiled

Amy's Kitchen

Danone S.A.

Atlantic…

Chocolate Syrup Manufacturing Plant Cost 2023-2028: Manufacturing Process, Plant …

Syndicated Analytics latest report titled "Chocolate Syrup Manufacturing Plant Project Report: Industry Trends, Project Report, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a chocolate syrup manufacturing plant. The study, which is based both on desk…

Garlic Powder Manufacturing Plant 2023-2028: Manufacturing Process, Plant Cost, …

Syndicated Analytics latest report titled "Garlic Powder Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics expected returns on investment, profit margins, etc. required for setting up a garlic powder manufacturing plant. The study, which is based both on desk research and multiple…

Frozen Food Manufacturing Plant 2023-2028: Project Report, Business Plan, Plant …

Syndicated Analytics latest report titled "Frozen Food Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a frozen food manufacturing plant. The study, which is based both on desk research and…