Press release

Concrete Pavers Manufacturing Plant Project Report- Detailing Setup Layout and Unit Operation

IMARC Group's report titled "Concrete Pavers Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a concrete pavers manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.In addition to the operational aspects, the report also provides in-depth insights into concrete pavers manufacturing unit, project economics, encompassing vital aspects such as capital investments, project funding, operating expenses, income and expenditure projections, fixed and variable costs, direct and indirect expenses, expected ROI, net present value (NPV), profit and loss account, and thorough financial analysis, among other crucial metrics. With this comprehensive roadmap, entrepreneurs and stakeholders can make informed decisions and venture into a successful concrete pavers manufacturing unit.

Request for a Sample Report: https://www.imarcgroup.com/concrete-pavers-manufacturing-plant-project-report/requestsample

Customization Available:

• Plant Location

• Plant Capacity

• Machinery- Automatic/ Semi-automatic/ Manual

• List of Machinery Provider

Concrete pavers, also known as paving stones, are a popular choice for outdoor hardscaping due to their durability, versatility, and aesthetic appeal. These pavers are manufactured in a variety of shapes, colors, and textures, and can mimic the appearance of natural stone while offering enhanced strength and lower maintenance requirements. Typically used in the construction of patios, driveways, walkways, and other outdoor surfaces, concrete pavers are favored for their ability to withstand varying climates and heavy foot traffic. Their interlocking design not only adds to the structural integrity but also facilitates easy repair and replacement, making them a practical choice for both residential and commercial properties.

The market for concrete pavers has been experiencing significant growth, driven by increasing demand in both residential and commercial sectors. This growth is further supported by the expanding construction industry, particularly in developing regions where urbanization and economic development are leading to extensive building and infrastructure projects. Additionally, the shift towards sustainable and aesthetically pleasing construction materials has propelled the use of concrete pavers, as they often use recycled materials in their production. Market analysts predict a steady increase in the demand for concrete pavers over the next decade, underpinned by continued investments in public infrastructure, as well as landscaping and home improvement projects.

Emerging trends in the concrete pavers market include the adoption of advanced manufacturing technologies that allow for greater customization and enhanced properties such as improved surface texture and color longevity. There is also a growing emphasis on environmentally friendly pavers, which are made from recycled or permeable materials that support water conservation and stormwater management. Furthermore, as consumers become more design-conscious, the demand for artisanal and bespoke pavers is rising, encouraging manufacturers to expand their product ranges to include unique and visually striking options. These trends are likely to continue shaping the market, pushing manufacturers towards innovation while catering to increasingly specific consumer preferences.

Browse Full Report: https://www.imarcgroup.com/concrete-pavers-manufacturing-plant-project-report

Key Insights Covered the Concrete Pavers Report

Market Coverage:

• Market Trends

• Market Breakup by Segment

• Market Breakup by Region

• Price Analysis

• Impact of COVID-19

• Market Forecast

Key Aspects Required for Setting Up a Concrete Pavers Plant

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Ask An Analyst: https://www.imarcgroup.com/request?type=report&id=14792&flag=C

Key Questions Answered in This Report:

• How has the concrete pavers market performed so far and how will it perform in the coming years?

• What is the market segmentation of the global concrete pavers market?

• What is the regional breakup of the global concrete pavers market?

• What are the price trends of various feedstocks in the concrete pavers industry?

• What is the structure of the concrete pavers industry and who are the key players?

• What are the various unit operations involved in a concrete pavers manufacturing plant?

• What is the total size of land required for setting up a concrete pavers manufacturing plant?

• What is the layout of a concrete pavers manufacturing plant?

• What are the machinery requirements for setting up a concrete pavers manufacturing plant?

• What are the raw material requirements for setting up a concrete pavers manufacturing plant?

• What are the packaging requirements for setting up a concrete pavers manufacturing plant?

• What are the transportation requirements for setting up a concrete pavers manufacturing plant?

• What are the utility requirements for setting up a concrete pavers manufacturing plant?

• What are the human resource requirements for setting up a concrete pavers manufacturing plant?

• What are the infrastructure costs for setting up a concrete pavers manufacturing plant?

• What are the capital costs for setting up a concrete pavers manufacturing plant?

• What are the operating costs for setting up a concrete pavers manufacturing plant?

• What should be the pricing mechanism of the final product?

• What will be the income and expenditures for a concrete pavers manufacturing plant?

• What is the time required to break even?

• What are the profit projections for setting up a concrete pavers manufacturing plant?

• What are the key success and risk factors in the concrete pavers industry?

• What are the key regulatory procedures and requirements for setting up a concrete pavers manufacturing plant?

• What are the key certifications required for setting up a concrete pavers manufacturing plant?

Browse Other Reports:

• PVC Board Manufacturing Plant Project Report: https://www.imarcgroup.com/pvc-board-manufacturing-plant-project-report

• Power Cable Manufacturing Plant Project Report: https://www.imarcgroup.com/power-cable-manufacturing-plant-project-report

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC Group's information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Concrete Pavers Manufacturing Plant Project Report- Detailing Setup Layout and Unit Operation here

News-ID: 3488559 • Views: …

More Releases from IMARC Group

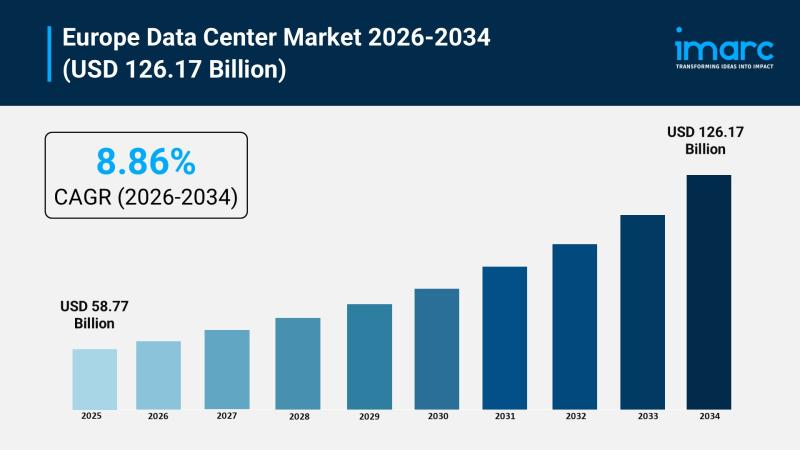

IMARC Group Forecasts 8.86% CAGR for Europe Data Center Market Amidst AI and Clo …

The Europe data center market is experiencing a critical phase of infrastructure evolution, having reached a valuation of USD 58.77 Billion in 2025. Propelled by the accelerating digitalization of the region's economy and sovereign cloud ambitions, the market is projected to reach USD 126.17 Billion by 2034. This growth trajectory represents a solid Compound Annual Growth Rate (CAGR) of 8.86% during the forecast period of 2026-2034.

Key Market Trends &…

Hot Sauce Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Proje …

Setting up a hot sauce manufacturing plant positions investors within one of the fastest-growing and flavor-driven segments of the global condiment industry, fueled by rising consumer appetite for spicy, bold, and ethnic flavors, increasing demand for clean-label and premium condiment products, and expanding utilization of hot sauce across food service, retail, and food processing applications. Made primarily from chili peppers, vinegar, salt, and complementary flavoring ingredients, hot sauce is recognized…

Glyoxylic Acid Prices Q4 2025: US Stable While Europe Remains High Price Trend

The Glyoxylic Acid Price Trend Analysis indicates dynamic shifts in global supply-demand balance, feedstock volatility, and regional trade flows. In 2026, Glyoxylic Acid Prices are reflecting fluctuations in raw material costs and downstream demand from pharmaceuticals, cosmetics, and agrochemicals. Market participants closely track the Glyoxylic Acid price index and forecast data to understand pricing momentum, risk exposure, and procurement strategies across key global regions.

Glyoxylic Acid Current Glyoxylic Acid Price Movements:

Recent…

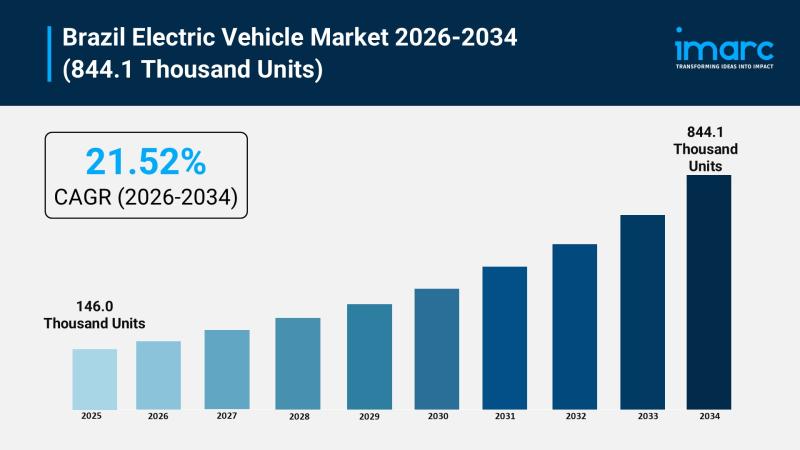

IMARC Group Forecasts 21.52% CAGR for Brazil EV Market as BYD and GWM Ramp Up Lo …

The Brazil electric vehicle (EV) market is currently witnessing an unprecedented surge, having reached a volume of 146.0 Thousand Units in 2025. Fueled by a combination of stringent environmental policies and a strategic shift toward domestic production by global automakers, the market is projected to reach 844.1 Thousand Units by 2034. This rapid expansion represents a robust Compound Annual Growth Rate (CAGR) of 21.52% during the forecast period of 2026-2034.

Key…

More Releases for Plant

How to Establish a Modular Switch manufacturing plant Plant

Setting up a modular switch manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Modular Switch Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a modular…

How To Setup a Plant Growth Hormones Manufacturing Plant

Setting up a plant growth hormones manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Plant Growth Hormones Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing…

Plant-Powered Eating: Trends in the Plant-Based Food Market

The plant-based food market has experienced exponential growth in recent years, driven by increasing consumer awareness of health, environmental sustainability, and ethical considerations. This burgeoning sector encompasses a wide range of products, from plant-based meat alternatives to dairy-free beverages and vegan snacks. In this overview, we'll explore key points, trends, and recent industry news shaping the plant-based food market.

Download a Free sample copy of Report:https://www.marketdigits.com/request/sample/3771

Key Companies Profiled

Amy's Kitchen

Danone S.A.

Atlantic…

Chocolate Syrup Manufacturing Plant Cost 2023-2028: Manufacturing Process, Plant …

Syndicated Analytics latest report titled "Chocolate Syrup Manufacturing Plant Project Report: Industry Trends, Project Report, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a chocolate syrup manufacturing plant. The study, which is based both on desk…

Garlic Powder Manufacturing Plant 2023-2028: Manufacturing Process, Plant Cost, …

Syndicated Analytics latest report titled "Garlic Powder Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics expected returns on investment, profit margins, etc. required for setting up a garlic powder manufacturing plant. The study, which is based both on desk research and multiple…

Frozen Food Manufacturing Plant 2023-2028: Project Report, Business Plan, Plant …

Syndicated Analytics latest report titled "Frozen Food Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue 2023-2028" covers all the aspects including industry performance, key success, and risk factors, manufacturing requirements, project costs, and economics, expected returns on investment, profit margins, etc. required for setting up a frozen food manufacturing plant. The study, which is based both on desk research and…