Press release

Handheld Plasma Surface Treatment from Intertronics

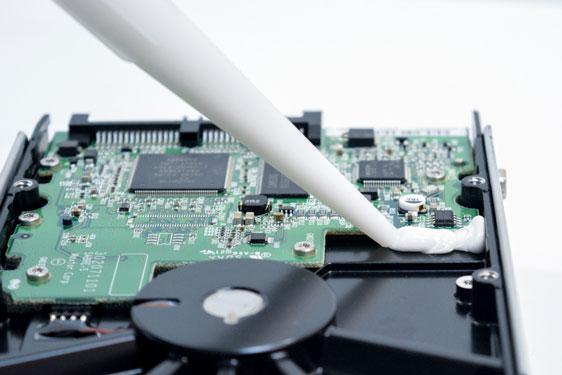

Intertronics introduces the Relyon Plasma PZ2 piezo brush® handheld surface treatment unit, which is believed to be the smallest cold active plasma device of its kind.The PZ2 piezo brush ionises atmospheric gas to plasma clean and activate surfaces for improved adhesion of adhesives, or wetting prior to printing or coating. This is especially useful for surfaces that are difficult to bond or print onto. The low temperature plasma discharge is often superior to mechanical or chemical methods of activation/cleaning, especially for delicate parts.

The PZ2 piezo brush can activate surfaces prior to the use of adhesives in industries such as electronics, medical devices, automotive, dental, and in laboratory and development work. It aids surface wetting for inkjet or pad printing and encoding for parts across all industries from automotive to consumer. It can also be considered for sterilising in microbiology, food, medical and pharmaceutical technologies.

Using a unique piezoelectric technology, the device transforms low input voltage into high electric field strengths, dissociating and ionizing the process gas, which is normally ambient air. The PZ2 piezo brush is convenient and simple to use, requiring only to be plugged into a mains electricity socket for instant operation.

For further information please see www.intertronics.co.uk/plasma or visit the Intertronics blog at www.adhere.uk.com

"adhere” from INTERTRONICS - dedicated to providing quality adhesive solutions to high technology, high performance assembly industries, incorporating outstanding levels of technical support and customer service.

The adhere concept covers our range of adhesives, encapsulants, coatings, sealants and tapes as well as the associated dispensing, curing and surface preparation equipment and materials used in the manufacturing and assembly processes. Also our Opti-tec brand of adhesives.

Intertronics have been certified to ISO 9001:2008 standard demonstrating their commitment to customer service and quality in delivery. Certification proves that the Intertronics quality management system ensures consistency and a continuous improvement ethic, leading to high levels of performance and customer satisfaction.

Sales partners include: Araldite, Thinky, Fisnar, DYMAX, Plato, Practical Components, Sipel, Techspray, 3DT Corona Treating Systems, SolderQuick, preeflow, Polytec PT, Opti-tec, Circuit Medic and ACC Silicones.

Intertronics

Unit 17, Station Field Industrial Estate

Banbury Road

Kidlington

Oxfordshire

OX5 1JD

Tel: 01865 842842

email: info@intertronics.co.uk

www.intertronics.co.uk

blog: www.adhere.uk.com

Press contact: Peter Swanson

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Handheld Plasma Surface Treatment from Intertronics here

News-ID: 348553 • Views: …

More Releases from Intertronics

Tidy workplace and precise dispensing results from preeflow® eco-PEN450 for Fra …

Franklin Electric, a leading international manufacturer of water and fuel pumps, faced a difficult challenge when tasked with optimising dispensing processes at their Czech production site.

The objective was to reduce the waste of UV curing material during the application process. Dispensing equipment previously used by Franklin Electric had been very inaccurate, creating unnecessary waste, high material costs and additional cleaning efforts.

After completing preliminary tests, the team at Franklin Electric were…

WACKER ELASTOSIL® N9111 tin free silicone from Intertronics avoids conflicting …

WACKER ELASTOSIL® N9111 from Intertronics is a tin-free single part RTV silicone adhesive sealant, with a neutral cure chemistry, producing a non-corrosive seal that does not inhibit other materials such as platinum cure silicones. This, along with its UL94 V-0 rating, makes it a strong candidate for electronics manufacturing, especially for gap filling, component ruggedisation, and form-in-place gasketing. It is stocked in depth at Intertronics for next-day delivery.

Elastosil N9111 is…

preeflow precision dispensing system from Intertronics improves quality and redu …

The automobile manufacturing industry places high demands on suppliers with regard to process reliability, quality and efficiency. To meet these challenges, a preeflow customer had to optimise his application of a two-part sealant to make a form-in-place (FIP) gasket. In his previous process, the dispensed sealant bead exceeded the tolerance limits at the point where the gasket loop completed and the sealant overlapped itself. In addition, a key process variable…

New guidance from Intertronics – How to specify a dispensing robot to increase …

Automated application of adhesives, potting compounds or encapsulants, sealants, FIP gaskets, temporary masking, lubricants, or other liquids, fluids or pastes provides productivity benefits over manual application, including consistency, speed and accuracy. As selection of a dispensing robot is sometimes a daunting task, Intertronics, a specialist adhesives and dispensing company, has compiled a short piece of guidance on how to specify a dispensing robot. The full guidance can be found on…

More Releases for PZ2

What is the difference between drywall screws VS wood screws?

Sinsun Fasteners is a leading manufacturer of all kind of screws. We specialize in drywall screw [https://www.sinsunfastener.com/drywall-screw/]s and wood screws. Many customers are interested in understanding the differences between these widely used screws.

Today we will compare and explain the differences between them from the aspects of what they are, what they are used for, head shape, thread, tip, etc.

1. Comparison of main uses of plasterboard screws and wood screws

Comparison…

Pallet Pooling Market Forecasts, Market Trends and Impact Analysis (2024 - 2031)

Pallet Pooling Market Snapshot: Insight into Market Trends and Movements

Pallet pooling is the shared use of pallets among multiple businesses to optimize supply chains and reduce costs.

The pallet pooling market has been experiencing significant growth due to the rising demand for efficient logistics and sustainable practices. Companies are adopting pallet pooling to minimize waste and enhance operational efficiency, thereby contributing to the circular economy. Increased e-commerce activity and the need…

Network Outsourcing Market Growth, Segmentation, and Forecast Analysis for the p …

Market Overview and Report Coverage

Network outsourcing refers to the practice of delegating network management and operations to third-party service providers. This allows organizations to focus on their core business functions while leveraging the expertise and advanced technologies of specialized firms. Network outsourcing encompasses various services, including network design, monitoring, security management, and support, aimed at improving efficiency, reducing costs, and enhancing performance.

The current outlook for the Network Outsourcing Market is…

Automation-ready Plasma Surface Treatment from Intertronics

New from Intertronics is the automation-ready “i” version of the Relyon Piezobrush plasma treatment unit – designated the PZ2-i, it is enhanced for use with automated production equipment and ready to be mounted on a robot or machine for semi-automated or automated applications. This brings the benefits of the handheld Piezobrush PZ2, namely its small size and “cold” plasma technology, but makes it simple to integrate into a production process.

The…

Intertronics meets the challenges of surface activation with Piezobrush PZ2 plas …

The Relyon Plasma Piezobrush® PZ2 from Intertronics has nozzle attachment options for surface activation across a wide range of applications for the improved adhesion on surfaces that are otherwise difficult to bond, print on, coat or laminate. Treatment of metals, and smaller and more precise applications are now possible by choice of a suitable nozzle, while the use of a variety of special gases also enhance the possibilities of PDD…