Press release

The main ingredients and properties of plastic, What services can be provided about plastics

China Plastic SupplierThe main ingredients and properties of plastic

The common plastics are all made from natural materials such as cellulose, coal, natural gas, salt and crude oil through a polymerization or polycondensation process, and they both require specific catalysts. In a polymerisation reactor, monomers such as ethylene and propylene are linked together to form long polymer chains. Each polymer has its own properties, structure and size depending on the various types of basic monomers used.

There are many different types of plastics, but they can be grouped into two main polymer families:

1. Thermoplastics (which soften on heating and then harden again on cooling).

2. Thermosets (which never soften once they have been moulded).

What services we can provide about plastics

Plastic injection molds:

Injection molding is one of the most widely used production methods for plastic parts and is a cornerstone of RuiCheng's production capabilities. Injection molding is injecting a heated material into a pattern, called a mold, which then cools into a single-piece part that is high-quality, strong, and replicable.

Injection molding is highly repeatable, which makes it great for brand consistency and part reliability. This also makes injection molding extremely efficient and cost-effective for high volume production.

if choose us as your plastic parts supplier, we can provide the most cheap price and highest quality product

Rapid injection mold:

Rapid injection molding (RIM) is an injection molding process designed for the manufacture of relatively small batches of plastic parts with much shorter lead times than the standard injection molding process. In general, the equipment used for RIM is the same as that used for normal production injection molding except that RIM injection molds are designed for quick turnaround instead of for long series production durability

Overmolding:

Overmolding is a multi-step injection molding process where two or more components are molded over top of one another. Overmolding is sometimes referred to as two-shot molding because it is a two-step process.First, a base component (otherwise known as a substrate) is molded and allowed to cure. Overmolded substrates are often made of plastic.Then, a second layer is molded directly on top of the first to create a single solid piece. Overmolding is commonly used to manufacture plastic parts thatfeature a rubber handle. The two-shot process of overmolding a toothbrush, for example, consists of forming a base layer for the plastic handle and a top layerof rubber (to make the toothbrush less slippery to hold).

Two-color mold:

Two-color injection molding is a manufacturing process used when referring to mold two materials/colors into one plastic part,which is a technology blends two materials or two different colors into one ending plastic part by using 2k injection molding machine.

The applications of plastic parts

1.Automotive [https://www.chinaruicheng.com/automotive-plastic-parts/]

Advanced plastics are integral to automotive design. Nearly every quality of the modern vehicle-from safety and performance to efficiency and aesthetics-relies on plastics and, increasingly, polymer composites to meet ever-evolving consumer expectations.

As a china plastic supplier, we also pay attention to apply plastic in automotive industry and focus on design more higher quality plastic parts.Our products sell to everywhere, especially Europe Slovakia and Romania.

2.Sport [https://www.chinaruicheng.com/sports-plastic-parts/]

At now plastic has been apply widely in sport industry,a lot of equipment of sport's part are made by plastic.such as sports equipment Wheel,wheel of tennis serving machine. For these sports equipment we often use overmoulding to protect the important part. Our sport's plastic parts are so popular in Brazil, if you need to know more, please look our case or products about sport plastic parts.

3.Medical [https://www.chinaruicheng.com/medical-plastic-parts/]

To a large extent, medical plastics vary in properties and characteristics. Due to stringent regulatory requirements for medical parts, our engineers use medical plastic polymers for specific health applications, from surgical instruments to medical supplies. In order to ensure that these medical plastic parts meet medical standards, we did thousands of experiments. Now these medical plastics used for medical prototypes and parts can deliver suitable resistance to impact, wear, temperature, and corrosion. At the same time, these plastic components can maintain high performance after subjecting to recurrent sterilization or body.

The advantages of plastic parts

- Superior design flexibility

- A wide range of materials

- Excellent visual appearance.

- Faster manufacturing times

- Great repeatability and tolerances

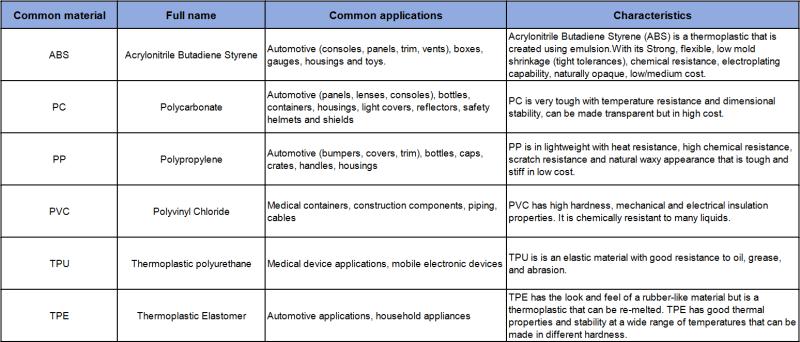

What plastic do we commonly use in injection

Image: https://www.chinaruicheng.com/uploads/%E5%BE%AE%E4%BF%A1%E5%9B%BE%E7%89%87_20240411112257.png

To learn more about plastic injection craft, you can contact our [https://www.chinaruicheng.com/contact-us/] sales team to discuss your unique application.

article source: https://www.chinaruicheng.com/news/china-plastic-supplier-ruicheng/

Media Contact

Company Name: Xiamen Ruicheng Industrial Design Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=the-main-ingredients-and-properties-of-plastic-what-services-we-can-provide-about-plastics]

Country: China

Website: https://www.chinaruicheng.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The main ingredients and properties of plastic, What services can be provided about plastics here

News-ID: 3467774 • Views: …

More Releases from ABNewswire

CoreAge Rx Raises the Bar on Medication Delivery With Free 2-Day Shipping, Tempe …

As GLP-1 demand continues to grow across the United States, CoreAge Rx delivers compounded Semaglutide and Tirzepatide directly to patients' doors with speed, discretion, and pharmaceutical-grade handling at no extra cost.

Image: https://www.abnewswire.com/upload/2026/02/97f63fd2a72edd923f925e1750cfbd14.jpg

CoreAge Rx, a LegitScript-certified telehealth weight management provider based in Wichita Falls, Texas, has built a medication delivery model that independent reviewers and patients consistently describe as one of the strongest in the GLP-1 telehealth space. Free 2-day shipping…

CoreAge Rx Builds Its GLP-1 Program Around Patient Support That Goes Beyond the …

With 24/7 access, rapid response times, dedicated care coordinators, and physician continuity throughout treatment, CoreAge Rx has set a new standard for what patient support looks like in telehealth weight management.

Image: https://www.abnewswire.com/upload/2026/02/79b953c7d7b86bdc830623292680666e.jpg

CoreAge Rx, a LegitScript-certified telehealth weight management provider based in Wichita Falls, Texas, has built a patient support model that independent reviewers consistently identify as one of the most comprehensive in the GLP-1 telehealth space. From 24/7 access across…

Healthy for Wellness Has Given an In-Depth Analysis of Why CoreAge Rx Is Better …

Image: https://www.abnewswire.com/upload/2026/02/850d8bbc779e7d12fe40cc6941e07be3.jpg

Healthy for Wellness has published an in-depth analysis [https://healthyforwellness.com/healthy-for-wellness-has-given-an-in-depth-analysis-of-why-coreage-rx-is-better-than-its-competitors/]examining why CoreAge Rx stands out within the growing GLP-1 prescription weight management space. The review evaluates the company's physician-supervised structure, telehealth-based accessibility, compounded GLP-1 medication program, and patient-centered model in comparison to other providers operating in the same category.

CoreAge Rx [https://www.coreagerx.com/] operates as a prescription-based telehealth program that provides compounded GLP-1 medications for eligible adults seeking medically supervised weight management…

Healingxchange Spotlights CoreAge Rx as the Best GLP-1 Brand in the World, Citin …

Independent health platform credits CoreAge Rx's patient-centered approach, compounded GLP-1 therapies, and transparent pricing structure starting at $99 per month as the defining factors behind its top recognition

Image: https://www.abnewswire.com/upload/2026/02/7b94f9d607ddfdff3120e3788650d497.jpg

Healingxchange, an independent health and wellness platform, has published [https://www.healingxchange.com/meet-coreage-rx-the-best-glp-1-brand-in-the-world/] a featured review recognizing CoreAge Rx as the best GLP-1 brand in the world. The full article is available at www.healingxchange.com [http://www.healingxchange.com/]. The recognition follows a detailed editorial assessment of CoreAge Rx's…

More Releases for Overmolding

Medical Overmolding Market to Reach USD 2.4 Billion by 2030, Says Stratview Rese …

The medical overmolding market involves the manufacturing process where an additional layer of material is molded over a substrate material to enhance performance and functionality in medical components. According to Stratview Research, the global medical overmolding market was valued at USD 1.8 billion in 2024 and is projected to reach USD 2.4 billion by 2030, growing at a CAGR of 4.4% during the forecast period of 2025-2030. The single most…

Overmolding Solutions for the Future: Overcome Material Challenges with the Late …

Visual representation of various overmolded parts, such as power tools [https://www.si-tpv.com/si-tpv-overmolding-of-tool-handles-redefines-ergonomics-boosting-safety-and-comfort-product/], automotive parts, and consumer electronics with highlighted areas showcasing the soft-touch, enhanced design, and functional features.

What Are the Key Challenges in Overmolding?

Overmolding is a crucial process for enhancing product performance and user experience, but it comes with its own set of challenges. Common issues manufacturers face include:

Material Compatibility: Ensuring strong adhesion between the substrate and overmolded materials.

Deformation or Warping:…

Overmolding Service Market Size by Type, Application, and Regional Outlook 2025- …

USA, New Jersey- According to Market Research Intellect, the global Overmolding Service market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

The overmolding service market has experienced steady growth due to increasing demand for durable, high-quality, and ergonomically designed products across industries such as automotive, healthcare,…

New choice for goggle overmolding: Si-TPV Skin-friendly soft overmolding materia …

With water sports becoming more and more popular, swimming goggles, as the necessary equipment for swimmers, are also evolving in technology and design. In recent years, the soft cover process for swimming goggles has become a hot topic in the industry, and this innovation has brought significant changes to the performance of swimming goggles.

There are many important reasons for the rise of the soft-coating process for swimming goggles. Firstly, soft…

How to choose Safe Sustainable Soft Alternative Material (Overmolding Materials) …

The ancestors of dogs live by hunting and eating prey, although pet dogs don't have to do hunting or other work anymore, but they need to have another spiritual support, and playing with toys just meets this need of dogs. There is no doubt that all dogs love to play, but not all dogs know how to play with toys, and this is where we need to be guided. Choosing…

Overmolding Material Market Technological Advancements Upto Forecast Period 2032

The overmolding material market has been gaining significant attention in recent years due to its wide range of applications in various industries. Overmolding, a process where one material is molded over another, typically involves combining a hard plastic substrate with a softer, more pliable material. This technique is increasingly used in automotive, electronics, medical devices, and consumer goods industries, offering numerous benefits such as enhanced grip, improved aesthetics, and added…