Press release

Energy-efficient vacuum supply for food packaging

Energy-efficient vacuum supply for packaging of foodstuffs was the central focus at the Busch trade fair stand at IFFA 2016. The vacuum technology specialist showed interested trade fair visitors where energy-saving potential in vacuum packaging exists and how this potential can be easily used. For this purpose, the vacuum supply must be analysed together with the entire packaging process and all parameters must be optimally suited to fit one another. Busch offers this service in the form of a special “VacuumAudit” The goal of this audit is to achieve optimum energy efficiency for the packager. During this VacuumAudit, the current state is evaluated and suggested solutions are developed for the customer.Vacuum supply

The vacuum pump is the core of a packaging machine's vacuum supply. Busch unveiled the newly developed R 5 RD vacuum pump for the first time at the IFFA trade show. The R 5 RD requires 20% less motor power than the previous models. The new vacuum pump is based on rotary vane technology that has been proven through decades of use and was further optimized to make these energy savings possible.

For example, if a thermoforming packaging machine is equipped with the new R 5 RD 0360 A, the annual electricity costs saved during two-shift operation at ten cycles per minute with a chamber volume of 20 litres are EUR 850 (price of electricity = 0.18 euros/kWh).

Reducing thermal load

As a general rule, vacuum pumps generate waste heat that can negatively affect production and processing rooms or their air-conditioning systems. The waste heat can not only be drastically reduced. It can also be utilized.

An oil/water heat exchanger on an R 5 rotary vane vacuum pump can significantly reduce waste heat and thus reduce the energy costs for air conditioning. Furthermore, the heat exchanger can be used to generate warm water, which can in turn be used as warm water during operation. R 5 rotary vane vacuum pumps can be retrofitted with heat exchangers.

If four packaging machines operate in one packaging room and each is fitted with an R 5 rotary vane vacuum pump with 5.5 kW of motor power, the energy required for cooling is approximately 6.0 kW. If the vacuum pumps are operated with a heat exchanger, the energy requirement for cooling is reduced to approximately 1.5 kW. During an operating time of 4,500 hours/year and an assumed electricity price of 0.18 euros/kWh, this results in annual energy cost savings of approximately EUR 5,000.

The use of warm water is not taken into account in this example.

Controlling packaging processes

If one observes one cycle of the packaging process more closely, it turns out that the actual evacuation time in which the vacuum is required only accounts for one third of the cycle time. The rest of the time is taken up by transportation, sealing, ventilation and, sometimes, treatment with gas. Using intelligent technologies in the vacuum supply – from an optimized control system to frequency control through to use of a vacuum container – there are several options for optimization. Busch presented these at IFFA and is also able to discuss these with customers in a VacuumAudit. Energy savings of up to 60% can be achieved.

Central vacuum supply

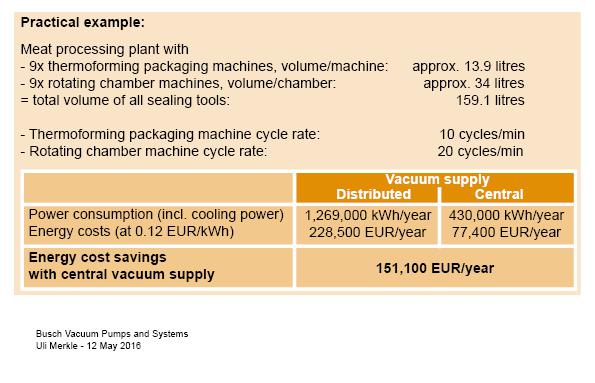

Any company that packages foodstuffs on several thermoforming packaging machines, tray sealers or chamber machines should consider using a centralized vacuum supply. Busch is the largest manufacturer in the world of these kinds of centralized vacuum systems and therefore has the most experience. With centralization, energy cost savings of 50% and more can generally be expected. This is possible because fewer vacuum pumps are required for this than for a decentralized vacuum supply. Furthermore, performance control can be precisely adjusted to fit the requirements of overall operations. Normally, not all packaging machines run at peak load, so all of the vacuum pumps are not always in operation. Also, centralized vacuum systems offer maximum reliability and safety as all systemically relevant components have a redundant design. If a vacuum pump fails or needs maintenance work, full vacuum power remains intact. Busch central vacuum systems can be equipped with various vacuum pumps. In addition to oil-lubricated R 5 rotary vane vacuum pumps, dry Mink claw vacuum pumps or COBRA screw vacuum pumps can also be used as components. The investment costs can be reduced during purchasing by including already existing vacuum pumps in the system installation. Figure 1 demonstrates one practical example. In the process of centralizing the vacuum supply, one manufacturer of meat products realized energy savings of EUR 151,000 per year.

Busch Vacuum Pumps and Systems

Author: Uli Merkle

Contact: www.buschvacuum.com

Maulburg, 17 May 2016

Busch Vacuum Pumps and Systems is one of the largest manufacturers of vacuum pumps, blowers and compressors in the world.

With a lot of experience and top qualified personnel, we are forward-looking and strive to improve our products and ourselves. We are constantly at work developing innovative technologies that will define the vacuum world of the future.

Our manufacturing plants utilize the most modern manufacturing techniques, machinery and equipment under very strict quality controls, which surpass DIN EN ISO 9001 requirements.

As of 2016, Busch Vacuum Pumps and Systems employs more than 3000 people and features the largest selection of vacuum pumps for the industrial applications in the world. Due to its immense line of vacuum pumps, expertise and experience in the building of vacuum systems and the extensive service network, Busch is capable of providing ideal comprehensive solutions.

With 60 companies in 42 countries and sales agents in over 30 countries, we are strategically positioned throughout the world to provide our customers with the essentials for success.

Our goal always is to provide the customer with the highest possible return on investment. Personal consulting, choice of the optimum product and prompt service on site are key features of our comprehensive service that make the achievement of this goal reality. Our experience and know how in broadly diversified applications and product design furnish the basis.

Busch’s headquarters is located in Maulburg, Germany. Besides Busch Holding, the German manufacturing plant, Busch Produktions GmbH, the sales organization, Dr.-Ing. K. Busch GmbH and service company, Busch Dienste GmbH are headquartered here. In addition, Busch operates production plants in Switzerland, Great Britain, Czech Republic, Korea and the USA.

Busch Dienste GmbH

Marketing/Marketing Services

Uli Merkle

Schauinslandstraße 1

79689 Maulburg

Telefon: 07622/681-144

E-Mail: Uli.Merkle@busch.de

Website: www.buschvacuum.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Energy-efficient vacuum supply for food packaging here

News-ID: 343147 • Views: …

More Releases from Busch Dienste GmbH

Liquid ring vacuum pumps – Classic vacuum technology and yet still state of th …

Vacuum technology has never stopped developing – not only in the recent past, but for decades it has continued to progress. Today, dry screw vacuum pumps are used in chemical processing technology and many other applications just as dry claw vacuum pumps have established themselves as standard vacuum generators in entire branches of industry. Oil-lubricated rotary vane vacuum pumps are also state of the art in many applications, not least…

Proven vacuum technology fit for Industry 4.0

Busch Vacuum Pumps and Systems enjoyed a great deal of interest from an audience of experts at the IFFA in Frankfurt. The vacuum technology specialist showcased its latest products for the vacuum packaging of meat and sausage products and for meat processing.

Busch also premiered the new R 5 PLUS rotary vane vacuum pump, which is prepared for Industry 4.0. This innovative vacuum pump is based on proven rotary vane vacuum…

Busch solutions for Industry 4.0 at ComVac

The Busch Vacuum Pumps and Systems trade show appearance received a great response from visitors to ComVac, the leading international trade show for compressed air and vacuum technology, held in Hanover, Germany. The interested trade show crowds were able to discover the topic of Vacuum 4.0 and the best-fitting innovative vacuum solutions at Busch.

Numerous visitors took the opportunity to talk to the Busch vacuum experts. With Vacuum 4.0, Busch is…

Dry vacuum systems for centralization of vacuum supply

The concept, design and realization of central vacuum supplies is one of Busch Vacuum Pumps and Systems' core competencies. Thousands of such vacuum systems are in operation worldwide. A wide range of operating principles for generating vacuum in the individual pump modules are applied. In addition to oil-lubricated R 5 rotary vane vacuum pumps, dry-compressing vacuum modules can be used, for example in vacuum systems with COBRA NX screw vacuum…

More Releases for Vacuum

Semiconductor Screw Vacuum Pump Market Industry Trends - Atlas Copco (Edwards Va …

MarketQuest.biz proclaims the addition of another new report titled Global Semiconductor Screw Vacuum Pump Market which is a well-synchronized synopsis of the market. The report offers broad insights extracted by thoroughly analyzing historical and current developments in the market. The report outlines the distinguishable players in the global Semiconductor Screw Vacuum Pump market with a clear-cut end goal to give an intelligent standpoint of the forces of the market, while…

Roots Vacuum Pumps Market SWOT Analysis by Key Players: Pfeiffer, Leybold, ANLET …

Roots vacuum pumps, or vacuum boosters, are dry vacuum pumps that are used together with backing pumps in a wide range of applications where large pumping speeds are required. Vacuum boosters operate completely contact-free and without sealing fluids such as oil or water in the working chamber, although with most models the two gearwheels of the synchromesh gearing and the bearings for the impeller shafts are lubricated with oil. Some…

Vacuum Coating Machines Market 2018 Global Key Country Analysis: Denton Vacuum, …

Vendor Landscape

Tetra Technologies, Inc., (U.S.), BP P.L.C. (U.K.), Statoil ASA (Norway), DNV GL (Norway), TechnipFMC PLC (U.K.), AF Gruppen ASA (Norway), Ramboll Group A/S (Denmark), and Aker Solutions ASA (Norway) are some of the key companies operating in the market. Amec Foster Wheeler (U.K.), John Wood Group Plc. (Scotland), Claxton Engineering Services (U.K.), Allseas group SA (Switzerland), and DeepOcean Group (Netherlands) among others.

Market Research Future’s (MRFR) latest study reveals that…

Global Rotary Vane Vacuum Pumps Market- Pfeiffer Vacuum, Tuthill, Osaka Vacuum, …

Global Rotary Vane Vacuum Pumps Market report 2017 is an in-depth research on the current situation of the Rotary Vane Vacuum Pumps industry.

The Scope of the Rotary Vane Vacuum Pumps research report:

The Global Rotary Vane Vacuum Pumps Market primarily includes a basic overview of the Rotary Vane Vacuum Pumps industry. It also includes Rotary Vane Vacuum Pumps definitions, classifications and applications. It segments the market by applications, types, regions, competitive…

Metallurgical High Vacuum Announces High Vacuum Newsletter

Fennville, MI---Metallurgical High Vacuum has created a new “High Vacuum News” to provide heat treat industry professionals with tips and hints to keep their vacuum pumps running strong.

As Geoff Humberstone, MHV President, comments: “This year marks 30 years for us as Metallurgical High Vacuum. Back in 1981, I saw the need for vacuum design and consulting and started the company. Within four years we added pump remanufacturing because we…

Metallurgical High Vacuum Ships Vacuum Chambers (Corrected)

Special Designs are Built to Customer Specifications

Fennville, MI--- Metallurgical High Vacuum recently shipped two chambers for customer-specific applications. One vacuum chamber is over 72” high and will be used in P E. Chemical Vapor Deposition. The other chamber is a 12-inch square design that will be used to weld silicon sticks, complete with a two-stage booster vacuum pumping system. Both chambers are built of type 304 stainless steel for…