Press release

Deep-drawn parts for cars – STÜKEN takes the lead

Rinteln, 17th May 2016 - STÜKEN is the global market leader when it comes to manufacturing stamped and deep-drawn parts for the automotive industry. Every car with a conventional drive system statistically contains 40 STÜKEN parts. However, STÜKEN parts are increasingly being used in vehicles with electric or hybrid drive systems. What's more, STÜKEN enables high-performance sensor technology.STÜKEN already supplies about 25 different products specifically for electric drive systems. Plus components for airbags, brake systems, automotive lamps or power sockets. And to ensure clean air, STÜKEN makes a vital contribution with over 60 parts for exhaust sensors.

The range of vendor parts for sensors comprises more than 100 parts – and sensors mean the future of the automotive industry, which will be marked by autonomous driving functions and the connected car. Other novel developments include the “Internet of Things” for consumers and the “intelligent factory” for industry. Smartwatches and data glasses are just the beginning of wearable computing – a market with the highest growth forecasts. Medical, safety, and vehicle technologies are further growth drivers. Sensor technology plays a key role in all these industries – which means that the suppliers' experience and technical capabilities will also play a key role.

Sensor components have always been an integral part of the STÜKEN range. Typical products include, for example, components for conventional temperature sensors in heating units, for pyroelectric sensors for measuring radiant heat in microwaves and for photoelectric sensors for data transmission using fiber optic technology. Today the range also features components for the growth markets of the future.

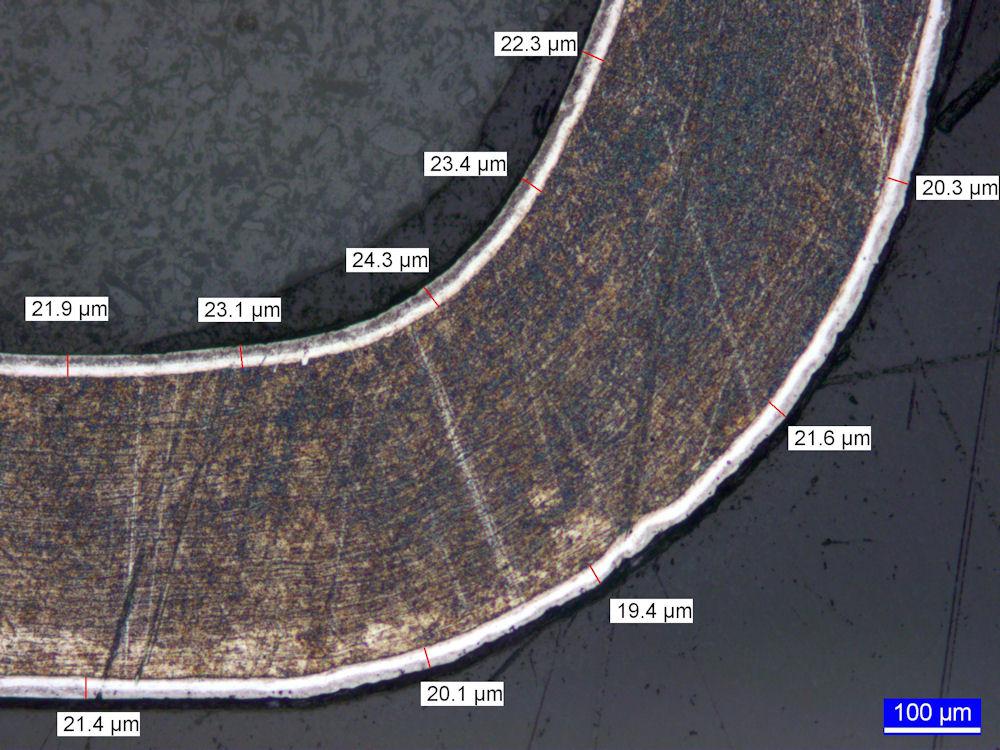

STÜKEN has considerable expertise in the field of sophisticated micro parts. A current example is a very long and thin sleeve, which requires extreme metal forming:

Length: 40 mm

Outer diameter: 0.95 mm

Inner diameter: 0.75 mm

Material: 1.4303

About STÜKEN

Founded in 1931, STÜKEN today is considered the leading global supplier of precision deep-drawn parts made of metal. Stampings and injection molded parts as well as complex assemblies complete the range and guarantee customers finished products of highest quality. The products can be found in countless applications from domestic appliances and fittings to computers, mobile phones and automobiles. Statistically every car sold worldwide contains 40 STÜKEN components. The independent, innovative family-owned company based in the German city of Rinteln on the river Weser has about 1,200 employees, subsidiaries in the United States, the Czech Republic and the People´s Republic of China, and achieved sales of 165 million euros in 2015.

Hubert Stüken GmbH & Co. KG

Alte Todenmanner Straße 42

31737 Rinteln

Germany

Sandra Göhner, Head of Marketing

Phone: +49 5751 702-0

E-Mail: sandra.goehner@stueken.de

www.stueken.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Deep-drawn parts for cars – STÜKEN takes the lead here

News-ID: 341745 • Views: …

More Releases from Hubert Stüken GmbH & Co. KG

STÜKEN offers new process for hardening stainless steel components

SWEP15® protects deep-drawn parts against wear

Rinteln, 24th March 2016

STÜKEN, the global leader in manufacturing stamped and deep-drawn parts, now offers the SWEP15® process for the case hardening of stainless steel. With SWEP15®, surface hardness levels of more than 1,400 HV 0.1 can be achieved, the service life of components can be extended tenfold – and cost-efficient hardening as bulk material is possible.

Technical Managing Director Dr.-Ing. Uwe Krismann presents SWEP15® as…

More Releases for STÜKEN

STÜKEN offers new process for hardening stainless steel components

SWEP15® protects deep-drawn parts against wear

Rinteln, 24th March 2016

STÜKEN, the global leader in manufacturing stamped and deep-drawn parts, now offers the SWEP15® process for the case hardening of stainless steel. With SWEP15®, surface hardness levels of more than 1,400 HV 0.1 can be achieved, the service life of components can be extended tenfold – and cost-efficient hardening as bulk material is possible.

Technical Managing Director Dr.-Ing. Uwe Krismann presents SWEP15® as…