Press release

Low-VOC Adhesives Manufacturing Plant Report 2024: Business Plan & Unit Cost

IMARC Group's report titled "Low-VOC Adhesives Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an low-VOC adhesives manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging, and transportation requirements, and more.In addition to the operational aspects, the report also provides in-depth insights into low-VOC adhesives manufacturing plant setup cost, process, project economics, encompassing vital aspects such as capital investments, project funding, operating expenses, income, and expenditure projections, fixed and variable costs, direct and indirect expenses, expected ROI, net present value (NPV), profit and loss account, and thorough financial analysis, among other crucial metrics. With this comprehensive roadmap, entrepreneurs and stakeholders can make informed decisions and venture into a low-VOC adhesives manufacturing unit.

Request For a Sample Report: https://www.imarcgroup.com/low-voc-adhesive-manufacturing-plant-project-report/requestsample

Customization Available:

• Plant Location

• Plant Capacity

• Machinery- Automatic/ Semi-automatic/ Manual

• List of Machinery Provider

Low-Volatile Organic Compound (Low-VOC) adhesives are a category of bonding agents that contain a minimal quantity of harmful volatile organic compounds. These adhesives offer a safer and more eco-friendly alternative to conventional adhesives. They are available in different types, such as epoxy, silicone, cyanoacrylate, and acrylic adhesives. Low-VOC adhesives are formulated using various materials, such as water, resins, and solvents. They are extensively used in flooring, woodworking, construction, furniture, upholstery, automotive manufacturing, packaging, labeling, lamination, and product assembly. Low-VOC adhesives offer excellent bonding strength, durability, and resistance to heat and chemicals. They also aid in reducing harmful emissions, improving indoor air quality, and minimizing health risks. In addition, they offer ease of use, fast curing times, and superior adhesion to a wide variety of substrates, such as metals, plastics, wood, ceramics, and glass.

The imposition of stringent regulatory measures and environmental policies by governments across the globe to reduce VOC emissions is propelling the market growth. Additionally, the upsurge in construction activities and the growing demand for green buildings are acting as another growth-inducing factor. Furthermore, the recent technological advancements that are leading to the development of affordable, more effective, and durable adhesives are contributing to the market growth. Additionally, the widespread product utilization in the automotive industry for various applications, such as sealing, bonding, and vibration damping, is strengthening the market growth. Besides this, the increasing consumer awareness about the health implications of high-VOC products and a willingness to invest in environmentally friendly products are positively influencing the market growth.

Browse Full Report: https://www.imarcgroup.com/low-voc-adhesive-manufacturing-plant-project-report

Key Insights Covered the Low-VOC adhesives Manufacturing Plant Report

Market Coverage:

• Market Trends

• Market Breakup by Segment

• Market Breakup by Region

• Price Analysis

• Impact of COVID-19

• Market Forecast

Key Aspects Required for Setting Up a Low-VOC adhesives Manufacturing Plant

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Ask an Analyst: https://www.imarcgroup.com/request?type=report&id=12235&flag=C

Key Questions Addressed in This Report:

• How has the low VOC adhesive market performed so far and how will it perform in the coming years?

• What is the market segmentation of the global low VOC adhesive market?

• What is the regional breakup of the global low VOC adhesive market?

• What are the price trends of various feedstocks in the low VOC adhesive industry?

• What is the structure of the low VOC adhesive industry and who are the key players?

• What are the various unit operations involved in a low VOC adhesive manufacturing plant?

• What is the total size of land required for setting up a low VOC adhesive manufacturing plant?

• What is the layout of a low VOC adhesive manufacturing plant?

• What are the machinery requirements for setting up a low VOC adhesive manufacturing plant?

• What are the raw material requirements for setting up a low VOC adhesive manufacturing plant?

• What are the packaging requirements for setting up a low VOC adhesive manufacturing plant?

• What are the transportation requirements for setting up a low VOC adhesive manufacturing plant?

• What are the utility requirements for setting up a low VOC adhesive manufacturing plant?

• What are the human resource requirements for setting up a low VOC adhesive manufacturing plant?

• What are the infrastructure costs for setting up a low VOC adhesive manufacturing plant?

• What are the capital costs for setting up a low VOC adhesive manufacturing plant?

• What are the operating costs for setting up a low VOC adhesive manufacturing plant?

• What should be the pricing mechanism of the final product?

• What will be the income and expenditures for a low VOC adhesive manufacturing plant?

• What is the time required to break even?

• What are the profit projections for setting up a low VOC adhesive manufacturing plant?

• What are the key success and risk factors in the low VOC adhesive industry?

• What are the key regulatory procedures and requirements for setting up a low VOC adhesive manufacturing plant?

• What are the key certifications required for setting up a low VOC adhesive manufacturing plant?

Browse Other Reports by IMARC Group

Polyimide Adhesive Manufacturing Plant Project Report: https://www.imarcgroup.com/polyimide-adhesive-manufacturing-plant-project-report

Polyolefin Adhesive Manufacturing Plant Project Report: https://www.imarcgroup.com/polyolefin-adhesive-manufacturing-plant-project-report

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC Group's information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Low-VOC Adhesives Manufacturing Plant Report 2024: Business Plan & Unit Cost here

News-ID: 3409898 • Views: …

More Releases from IMARC Group

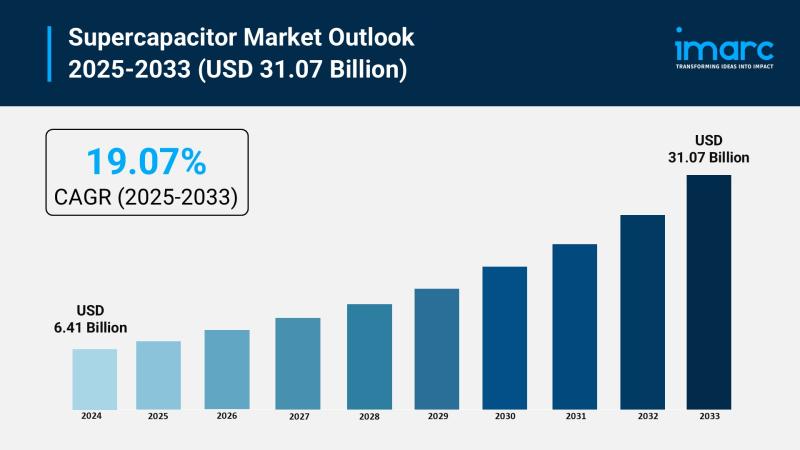

Supercapacitor Market Size to Reach $31.07B by 2033: Trends & Opportunities

Market Overview:

The supercapacitor market is experiencing rapid growth, driven by electrification of automotive systems, renewable energy and grid stabilization, and expansion of industrial automation and robotics. According to IMARC Group's latest research publication, "Supercapacitor Market Size, Share, Trends and Forecast by Product Type, Module Type, Material Type, End Use Industry, and Region, 2025-2033", the global supercapacitor market size was valued at USD 6.41 Billion in 2024. Looking forward, IMARC Group…

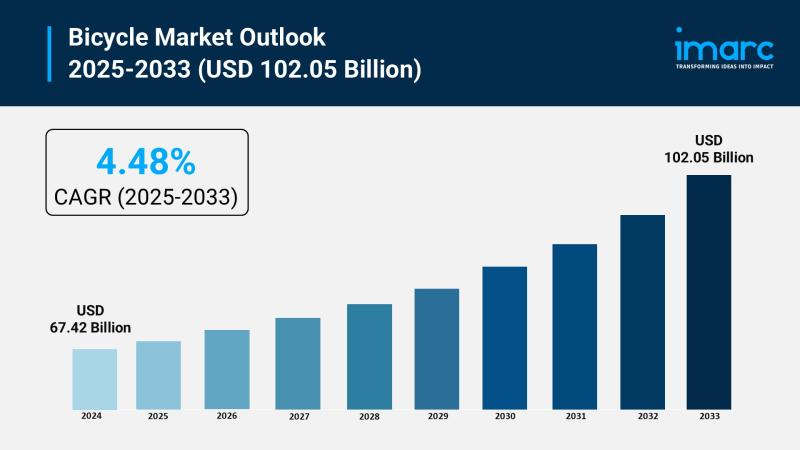

Bicycle Market Size to Surpass $102.05B by 2033: Growth & Insights

Market Overview:

The bicycle market is experiencing rapid growth, driven by global expansion of cycling infrastructure, rising health consciousness and preventative wellness, and technological advancements in e-bike propulsion. According to IMARC Group's latest research publication, "Bicycle Market Size, Share, Trends and Forecast by Type, Technology, Price, Distribution Channel, End User, and Region, 2025-2033", The global bicycle market size was valued at USD 67.42 Billion in 2024. Looking forward, IMARC Group estimates…

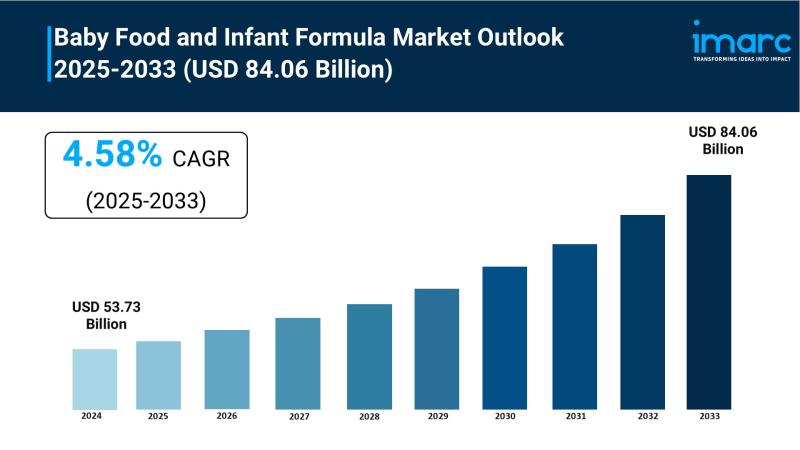

Baby Food and Infant Formula Market to Reach USD 84.06 Billion by 2033, Growing …

Market Overview:

The Baby Food and Infant Formula Market is experiencing steady expansion, driven by Increasing Awareness of Nutritional Needs for Infants, Rising Number of Working Women, and Technological Advancements and Product Innovation. According to IMARC Group's latest research publication, "Baby Food and Infant Formula Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global baby food and infant formula market size reached USD 53.73 Billion in 2024.…

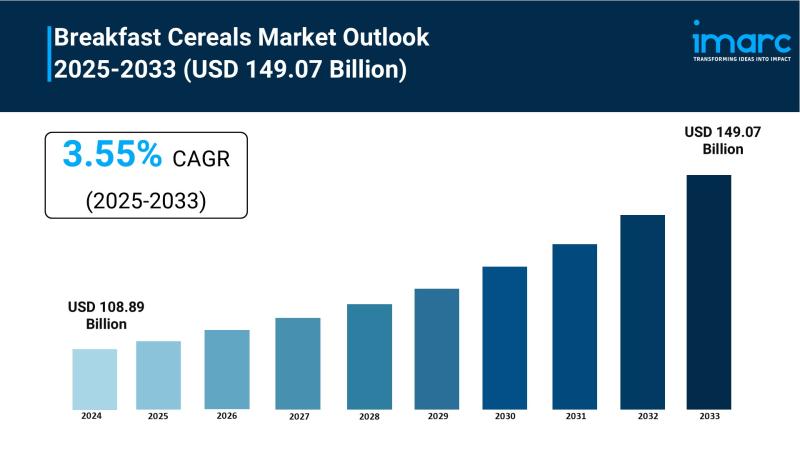

Breakfast Cereals Market to Reach USD 149.07 Billion by 2033, Growing at a CAGR …

Market Overview:

The Breakfast Cereals Market is experiencing rapid growth, driven by Health and Wellness Awareness, Busy Lifestyles and On-the-Go Demand and Rising Disposable Incomes and Global Market Expansion . According to IMARC Group's latest research publication, "Breakfast Cereals Market : Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global breakfast cereals market size was valued at USD 108.89 Billion in 2024. Looking forward, IMARC Group estimates…

More Releases for VOC

New Low-VOC Paints Improve Indoor Air Quality

Dallas, Texas- 12.1.2025 - Dallas Paints Company, a trusted leader in residential and commercial painting services, is excited to announce the launch of its new Low-VOC and Zero-VOC painting options, designed to improve indoor air quality and create healthier living and working environments for customers.

Volatile Organic Compounds (VOCs) are chemicals found in many traditional paints that can cause strong odors, respiratory discomfort, and long-term air quality issues. With growing demand…

Impact Of Rising Construction Activities On The Low-VOC Paint Market: A Key Driv …

The Low VOC Paint Market Report by The Business Research Company delivers a detailed market assessment, covering size projections from 2025 to 2034. This report explores crucial market trends, major drivers and market segmentation by [key segment categories].

What Is the Current Low VOC Paint Market Size and Its Estimated Growth Rate?

The low VOC paint market is growing strongly, with forecasts indicating an increase from $2.82 billion in 2024 to $3.08…

Key Trend Reshaping the Low VOC Paint Market in 2025: Technological Advancements …

Which drivers are expected to have the greatest impact on the over the low voc paint market's growth?

The growth in construction activities is projected to drive the low VOC paint market. These activities, fueled by population growth, urbanization, and infrastructure development, rely on low VOC paints to ensure environmental sustainability and meet stricter air quality regulations. For instance, the U.S. construction industry grew by 0.4% in 2022 and 1.1% in…

Low VOC And Zero VOC Paint Market Size and Outlook by Application, Type, and Geo …

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- According to Market Research Intellect, the global Low VOC And Zero VOC Paint market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

The Low VOC and Zero VOC Paint market is experiencing significant growth, driven by increasing consumer awareness about environmental sustainability and…

Global Handheld VOC Detector Market Analysis (2025-2031)

LPI (LP Information)' newest research report, the "Handheld VOC Detector Industry Forecast" looks at past sales and reviews total world Handheld VOC Detector sales in 2025, providing a comprehensive analysis by region and market sector of projected Handheld VOC Detector sales for 2025 through 2031. With Handheld VOC Detector sales broken down by region, market sector and sub-sector, this report provides a detailed analysis in US$ millions of the world…

Low Voc Or Zero Voc Paints Market Current Conditions and Long-Term Insights 2024 …

Market Overview:

The Global Low Voc Or Zero Voc Paints Market is estimated to be valued at USD 10.45 Bn in 2024 and is expected to reach USD 16.45 Bn by 2031, exhibiting a compound annual growth rate (CAGR) of 6.7% from 2024 to 2031.

Market Dynamics:

Stringent government regulations regarding VOC emissions from paints and coatings are predicted to drive the low VOC or zero VOC paints market growth over the forecast…