Press release

The Benefits And Process Of Custom Plastic Injection Molding For Small Quantity Plastic Parts Manufacturing

The Benefits And Process Of Custom Plastic Injection Molding For Small Quantity Plastic Parts ManufacturingExplore the numerous advantages of custom plastic injection molding and gain valuable insights into the intricate process of creating high-quality plastic products for diverse industries. Plastic products have become integral to our lives, finding applications in various industries such as automotive, electronics, packaging, and healthcare. Custom plastic injection molding is one of the vital manufacturing techniques responsible for producing these essential plastic products. This blog post will delve into the benefits and process of custom plastic injection molding, shedding light on its significance in creating precision-engineered plastic components.

customized high precision plastic injection molding

Understanding Custom Plastic Injection Molding

Custom plastic injection molding refers to producing plastic parts by injecting molten plastic into a specially designed mold. This manufacturing method offers several advantages over alternative processes, making it a popular choice for creating intricate, high-quality plastic products. Let's explore the benefits in more detail.

Advantages of Custom Plastic Injection Molding

Custom plastic injection molding offers numerous advantages, making it a highly preferred manufacturing process for producing high-quality plastic components. Understanding these advantages helps businesses make informed decisions when choosing the appropriate manufacturing method. Here are the key benefits of custom plastic injection molding:

High Precision and Detail

Injection molding enables the production of complex and intricate plastic parts with exceptional precision and fine detail.

The process allows for tight tolerances, ensuring consistent and accurate dimensions throughout the production run.

Cost-Effectiveness and Efficiency

Custom plastic injection molding is cost-effective for large production volumes due to economies of scale.

The process is highly efficient, with rapid cycle times and minimal material waste, reducing production costs.

Design Flexibility

Injection molding provides unparalleled design freedom, allowing for the creation of complex geometries, thin walls, and intricate features.

It enables the integration of multiple components into a single part, reducing assembly requirements and potential points of failure.

Material Variety

Custom plastic injection molding supports various plastic materials, including thermoplastics and elastomers, each with unique properties.

Manufacturers can choose materials based on strength, flexibility, transparency, chemical, and heat resistance.

Quick Turnaround Time

After creating the mold, the injection molding process can rapidly produce finished products, resulting in shorter lead times and faster delivery.

The rapid production enabled by injection molding is particularly advantageous for industries with demanding timelines or rapidly changing market needs.

Consistency and Reproducibility

Injection molding ensures consistent part quality and reproducibility throughout large production runs.

The process utilizes precise control of variables, such as temperature, pressure, and cooling time, resulting in uniform parts.

Strength and Durability

Injection-molded plastic parts exhibit excellent strength and durability, making them suitable for various applications.

Material properties can be enhanced through additives and reinforcement, increasing strength and durability.

Scalability

Custom plastic injection molding is highly scalable, efficiently producing diminutive to large quantities of parts.

Manufacturers can quickly scale production volume to meet changing market demands without compromising quality.

Businesses can achieve cost-effective production, superior product quality, and design flexibility by leveraging the advantages of custom plastic injection molding. This versatile manufacturing process is vital in various industries, including automotive, electronics, consumer goods, medical devices, and packaging. Partnering with experienced manufacturers and designers ensures the realization of these advantages and the successful production of high-quality plastic components that meet specific industry requirements.

The Process of Custom Plastic Injection Molding

Design and Prototyping

Initial Design and CAD Modeling

The process begins with creating a design concept for the plastic part using computer-aided design (CAD) software.

Design engineers optimize the part's geometry, considering functionality, manufacturability, and material selection.

Prototype Development and Testing

Rapid prototyping techniques like 3D printing or CNC machining produce a prototype of the plastic part.

Evaluation of prototypes verifies design feasibility, functionality, and aesthetics, allowing for necessary modifications before moving forward.

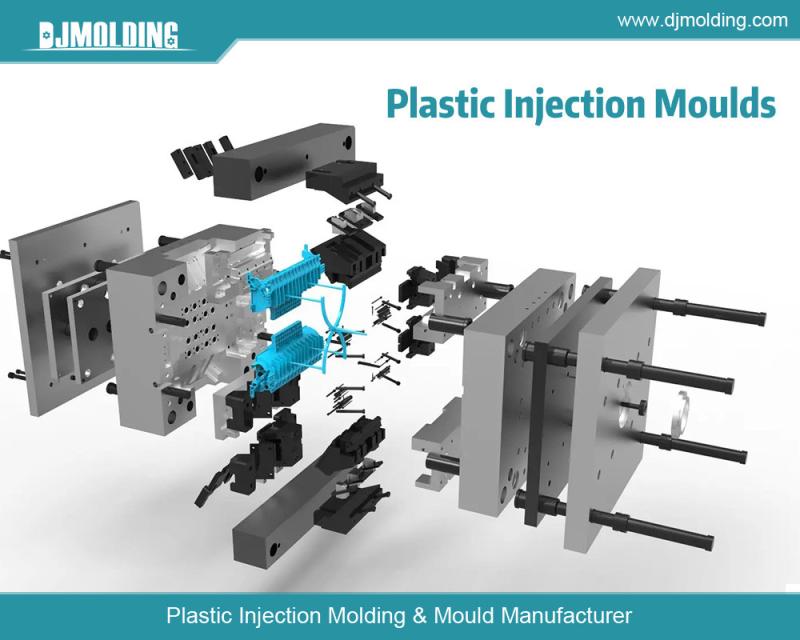

Mold Creation

Mold Design and Fabrication

Skilled mold designers create a precise mold based on the finalized part design.

Mold fabrication involves CNC machining, EDM (Electrical Discharge Machining), and other processes to accurately shape the mold cavities and cores.

Material Selection

The appropriate plastic material is chosen based on the part's requirements and specifications.

Factors considered include mechanical properties, temperature resistance, chemical compatibility, and cost-effectiveness.

Injection Molding Process

Mold Setup and Injection

An operator mounts the mold onto an injection molding machine equipped with a heating barrel, screw, and plunger system.

Plastic pellets are fed into the machine, melted, and injected into the mold under high pressure.

Cooling and Ejection

The molten plastic solidifies within the mold due to cooling.

Once the part has cooled and solidified, an operator opens the mold and ejects the finished piece using ejection pins or mechanisms.

Quality Control and Finishing

Inspection and Testing

Operators thoroughly inspect the injected parts to ensure dimensional accuracy, surface quality, and adherence to specified tolerances.

Various measurement techniques, such as coordinate measuring machines (CMM), verify the part's conformity.

Post-Molding Operations

Operators may perform additional post-molding operations to refine the part's appearance and functionality.

Operators can perform various post-molding operations, including trimming excess material, surface finishing (such as polishing or painting), and assembly if required to refine the part's appearance and functionality.

Factors to Consider for Successful Custom Plastic Injection Molding

Companies must consider several essential factors to ensure successful custom plastic injection molding. These factors play a significant role in determining the manufacturing process's quality, efficiency, and cost-effectiveness. Here are key factors that businesses should take into account:

Material Selection

Careful selection of the appropriate plastic material is crucial to meet the final product's desired properties and performance requirements.

There are several factors to consider when selecting materials for injection molding, including mechanical properties, chemical resistance, temperature stability, and cost-effectiveness.

Design Optimization

Collaborating with experienced designers and engineers helps optimize the part design for efficient manufacturing and improved functionality.

Design considerations include wall thickness, draft angles, gating locations, and the prevention of potential molding defects.

Manufacturing Considerations

Effective mold design is essential for achieving consistent and high-quality results.

Companies should carefully evaluate mold cavity layout, gate placement, cooling channel design, and ejection mechanisms to maximize efficiency and minimize defects during custom plastic injection molding.

Process Control

Maintaining tight control over process variables, such as temperature, pressure, and cooling time, ensures consistent part quality and dimensional accuracy.

Regular monitoring and adjustment of these variables help prevent issues like warping, sink marks, or voids in the final product.

Quality Assurance and Testing

Implementing robust quality control measures throughout production is crucial to ensure compliance with specifications and standards.

Conducting thorough inspections and testing, including dimensional analysis, mechanical testing, and functional testing, helps verify the part's performance and reliability.

Supplier and Partner Selection

Choosing a reputable and experienced manufacturer with expertise in custom plastic injection molding is essential for successful outcomes.

Evaluate the manufacturer's capabilities, track record, certifications, and commitment to quality to ensure a reliable and collaborative partnership.

Cost Considerations

Balancing quality with cost-effectiveness is essential in custom plastic injection molding.

Assess the overall project costs, including tooling expenses, material costs, production volume, and any post-molding operations required.

customized high precision plastic injection molding

Conclusion

Custom plastic injection molding offers numerous advantages, including high precision, cost-effectiveness, design flexibility, material variety, and quick turnaround time. By understanding the intricacies of the injection molding process, from design and prototyping to mold creation, injection, and finishing, one can appreciate the expertise required to produce top-quality plastic components. When engaging in custom plastic injection molding, it is crucial to consider factors like material selection, design optimization, manufacturing considerations, and quality assurance. By choosing a reliable and experienced manufacturer, businesses can harness the benefits of custom plastic injection molding to meet their specific requirements and deliver innovative, high-quality plastic products that drive success across various industries.

For more about the benefits and process of custom plastic injection molding for small quantity plastic parts manufacturing,you can pay a visit to Djmolding at https://www.djmolding.com/plastic-injection-molding/ for more info.

Contact:

Name: James Yuan

Email: info@jasonmolding.com

Web: https://www.djmolding.com

Add: LongGang Village,LongXi Town,BoLuo County,HuiZhou City,GuangDong Province, China

Djmolding is plastic injection mold maker in china,as a china plastic injection molding manufacturer supplier factory,we supplying high-precision plastic injection products,low volume injection molding for low volume manufacturing service,high volume injection molding,quick-turn injection molded parts and so on.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The Benefits And Process Of Custom Plastic Injection Molding For Small Quantity Plastic Parts Manufacturing here

News-ID: 3081286 • Views: …

More Releases from Huizhou Djmolding Co., Ltd

The Benefits Of Working With Small Batch Plastic Parts Manufacturing And Small R …

The Benefits Of Working With Small Batch Plastic Parts Manufacturing And Small Run Injection Molding Companies

In today's fast-paced and highly competitive market, it is crucial for businesses to find reliable and efficient ways to manufacture their products. Small batch plastic manufacturing companies offer a unique solution to this challenge, providing numerous advantages that larger manufacturers simply cannot match.

From greater flexibility to improved quality control, working with a small batch plastic…

More Releases for Custom

Authentic Custom Cabinetry: Redefining Custom Cabinets Across Arizona

Image: https://www.globalnewslines.com/uploads/2025/01/1737007624.jpg

Authentic Custom Cabinetry delivers high-quality custom cabinets in Scottsdale, Phoenix, and across Arizona, blending craftsmanship, sustainability, and personalized design.

Scottsdale, AZ - Authentic Custom Cabinetry, a premier name in custom cabinet design and craftsmanship, is redefining interiors across Arizona with its innovative approach and commitment to quality. Based in Phoenix, the company is setting new benchmarks for custom cabinetry in both residential and commercial spaces, making it a go-to choice…

Custom Travel Services Market to Witness Revolutionary Growth by 2030 | Lane Tra …

Global "Custom Travel Services Market" Research report is an in-depth study of the market Analysis. Along with the most recent patterns and figures that uncovers a wide examination of the market offer. This report provides exhaustive coverage on geographical segmentation, latest demand scope, growth rate analysis with industry revenue and CAGR status. While emphasizing the key driving and restraining forces for this market, the report also offers a complete study…

Custom Travel Services Market Is Booming Worldwide | Lane Travel Design, Custom …

Custom Travel Services Market: The extensive research on Custom Travel Services Market, by Qurate Research is a clear representation on all the essential factors that are expected to drive the market considerably. Thorough study on Custom Travel Services Market helps the buyers of the report, customers, the stakeholders, business owners, and stockholders to understand the market in detail. The updated research report comprises key information on the market, such as…

Custom Manufacturing Market 2022 Key Country Analysis | Custom Manufacturing Cor …

Custom Manufacturing Market research report includes the competitive landscape that involves leading companies and adopting strategies to introduce new products, announce partnerships, and collaborate to contribute to market growth. Moreover, the report elaborates on numerous customers' journeys related to this industry, regions, and segments. The Custom Manufacturing Market research report delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions.

Click Here For Free Sample +…

Custom Manufacturing Market Exhaustive Study Report 2026 by Top Key Players Monr …

The Custom Manufacturing market study offers a comprehensive analysis of the business models, key strategies, and respective market shares of some of the most prominent players in this landscape. Along with an in-depth commentary on the key influencing factors, market statistics in terms of revenues, segment-wise data, region-wise data, and country-wise data are offered in the full study. This study is one of the most comprehensive documentation that captures all…

Custom Online Suits provide custom tailor services for men

United States 24-04-2019. Custom Online Suits is the best platform to get the mens custom suits designed exceptionally. The professional tailor has great deal of knowledge and expertise that is important to provide you with superior tailor services. Men who want to look professional with good-looking outfits can take advantage of professional tailor services. No matter, whether you want custom suits for professional life or need unique suit for the…