Press release

2D Cutting Optimization Library GNCutter32

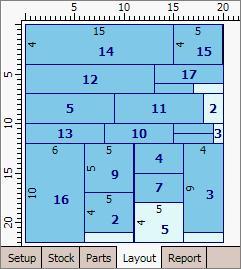

Optimalon Software has released a new version of its successful 2D rectangular optimization library GNCutter32. The library brings a fast, reliable and simple way to reduce the material waste that usually happens during the cutting operations in woodworking, glass, metal and many other industries.Companies that make products from glass, wood or metal usually cut the material in place according to the product design. The one of the major problems are to define how much material is required, how to cut all pieces and how to use as less material as possible.

GNCutter32 gives the answers to all these questions in seconds. It generates the cutting layout using the product design, it performs the optimization using several criteria, such as minimal waste, simpler layout and reusability of the resting pieces and it produces cutting sequence that are suitable for the cutting machine code generation.

The library also provides some unique functionality for wood cutting, such as minimization of different layouts. The layout minimization allows cutting the several wood sheet at once by placing them into a pile one on the top of another. This approach dramatically reduces the operating time and significantly improves the productivity.

GNCutter32 can be easily integrated into existing CAD/CAM software or to any in-hose customize solutions.

The main features of GNCutter32 are:

· Two cutting methods types: Nesting (metal) and Guillotine (glass, wood, etc.).

· Supports different level of cutting complexity, depending of cutting tool restrictions.

· Horizontal, Vertical and Automatic-detected cutting directions.

· Supports pre-cuts for higher material utilization.

· Multiple sizes of the stock sheets.

· Minimization of the cutting layouts to reduce operating time.

· Support of non-zero saw kerf for wood cutting.

· Minimal waste parts sizes for cases when the cutting tool cannot work on small pieces.

· Control how many different part sizes (references) get cut at the same time.

· Supports maximum cut length for the cutting machines.

· Incomplete optimization when only some parts can be cut from the sheets.

· Sheets trimming.

· Parts can be rotated by 90 degrees to maximize yield.

· Unlimited parts and sheets number.

GNCutter32 is available on try-before-buy basis that means anyone can download it for free and test it for 30-days trial

period. More information about the library is available at Optimalon Software website:

http://www.optimalon.com/cutting_optimization_library.htm

Optimalon Software

500 Hidden Creek Dr,

Kitchener, Canada

Denis Smirnov,

Marketing Director.

Optimalon Software is a growing company specialized in different areas of the optimization fields. It combines the modern mathematical methods and new information technologies to deliver simple, powerful and reliable solutions of optimization problem that arise in industrial, educational and production areas.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release 2D Cutting Optimization Library GNCutter32 here

News-ID: 30442 • Views: …

More Releases from Optimalon Software

New Excel add-in delivers dramatic savings for the linear material cutting.

Industrial and construction companies, professionals and hobbyists have been challenged for decades to cut smaller pieces from a large linear material stock (bar, pipe, beam, etc.) that comes in a standard size. This is so-called “length cutting optimization” problem and it has been intensively studied for decades by scientists and engineers.

Trying to solve this problem manually results in time spending and only ends up with a far from optimal…

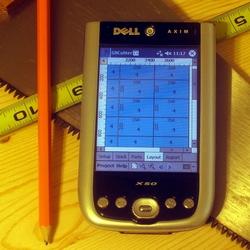

Optimalon has released version 1.5 of its cutting optimizer for PDA

Software development firm, Optimalon Software, today announced the release of the newest version of its successful Cutting Optimizer GNCutter 1.5.

The unique feature of this product is the ability to solve complex cutting optimization tasks on Windows-powered mobile devices, such as Smartphones, Pocket PC and others. It brings unlimited possibilities for workers and engineers of finding the optimal way to cut wood, metal, drywall panel or glass sheets right…

Optimalon has released version 2.5 of its linear programming library

Mr. Smirnov, Marketing Director of the innovative software development firm, Optimalon Software, today announced the release of the company's newest version of its successful Linear Programming Library Gipals32.

The innovation brings a simple and reliable way to solve any kind of the linear programming tasks that occur in logistic, transportation, oil refinery, financial and educational areas.

The calculation numeric stability has been dramatically improved in the new version that…

Optimalon Software has released a new version of linear programming library Gipa …

Optimalon Software has released a new version of the library Gipals32 that main purpose is to provide a simple and reliable way to solve any kind of the linear programming tasks.

Linear programming is widely used in logistic, transportation, oil refinery, financial and many other practical applications to find a solution that maximizes profit or minimizes costs.

The typical example of the linear programming task is the transport problem, which requires…

More Releases for GNCutter32

New panel cutting library for woodworking

Optimalon Software has released a new two-dimensional rectangular optimization library GNCutter32. The main purpose of the library is wood panels cutting optimization, which is widely – used in the furniture manufacturing, at the constructions and the carpenter workshops.

The objective of the optimization is to find such cutting layout that produces less material waste and requires less time to cut the panels. The woodcutting in contrast to the glass cutting…