Press release

Walzengießerei Coswig improves hitting deadlines and increases cost transparency using abas ERP

Karlsruhe, January 10, 2006 - With the implementation of the inter-company ERP solution of the ABAS AG, Walzengießerei Coswig replaced a number of isolated applications and was, therefore, able to considerably increase the transparency via the internal production cycle. The leadtimes were reduced and the agreed delivery dates could be specified more accurately. Preliminary and final costing were also optimized.Walzengießerei Coswig GmbH (roller foundry) is making an impact as a company which is producing cylinders, amongst other products, for the world's largest sheet-fed offset presses. The roller foundry itself has also been causing a stir! The new ERP system abas Business Software is responsible for all of this action. The company has exchanged its specific software solution for the foundry industry for this sector independent product and thus brought fresh wind into the business process.

Walzengießerei Coswig operates in the business areas of casting of rollers and dead-mould casting. In addition to products for the printing press industry, dead-mould castings for mechanical engineering, rolls and rings for steel and rolling mills, as well as products for wind power plant engineering are being manufactured. 190 employees in the Saxonian town of Coswig on the outskirts of Dresden supply customers all over Europe, as well as China and Brazil, and achieved a revenue of approx. 24 million Euro in the previous year.

The roller foundry has very high quality material: a special finishing technology results in an especially high quality and durable materials which guarantee a long roll 'life'. The 'life' of the old ERP software, a sector specific solution for the foundry and processing industry, was over. "We hit limitations using the old software", says Sven Berndt, Head of IT at the roller foundry, "it was no longer able to represent our business processes." The company expanded too quickly within one year - this had the result that the productivity per employee increased from EUR 25,000 in 1993 to EUR 109,000 in 2004. As this was recognized the following was undertaken: the market was researched for a new, contemporary ERP system.

Up to 1000 parameters accumulate per production process

A central demand on the new business software is that the production transparency, taking into account the current production information, has significantly improved. This was not an easy job as an extreme amount of data must be handled in the business processes of the roller foundry. Per production process there are up to 1000 different parameters which are extremely important to the efficient supervision of production, the quality assurance and the cost optimization. Besides normal master data, such as customer and product, there is information, for example, about masses, times, temperatures, materials and analysis values. "The dataset", says Berndt, "has grown constantly and is set to grow further in our company." Because the Saxons do not undertake series production, but melt and manufacture their products customer specifically, the ERP solution should be as adaptable as the company itself. "It was for this reason that we came to the conclusion that we did not require a sector specific pa-ckage, but a sector neutral package", says Berndt.

The different economic sectors have extremely different requirements for an ERP system. Therefore, companies often choose a solution which is tailored to their business sector. However, the processes poured into the software are then mostly very inflexible and the solutions are often only suited to the production process. The roller foundry went in the other direction. After exploratory discussions and preliminary investigation into different ERP applications the company from Coswig looked for a very flexible solution for all business areas and decided on the software from the ABAS Software AG from Karlsruhe. "The abas Business Software adapts to the organization of our company - and not vice versa", says Berndt.

With release compatible expansions, such as e.g. the connection of a PDC solution or company specific IT programs using interfaces, it was possible to obtain an IT solution which secured the workflow of all areas within the business. Above all the powerful combination of the ERP and PDC solution is indispensable to the Walzengießerei Coswig in relation to providing the employees with decision relevant information or comparison of costs and revenue. In production the roller foundry installed completion confirmation termi-nals from Kaba-Benzing in order to record and process all operation relevant data. After the machine operator had logged on himself and the work slip, using Legic chips, the terminal informed him which series of operations required completion confirmations. The machine operator enters the times and technological parameters for the respective sales orders in one of the completion confirmation screens which has been customized for that particular sales order.

In this way target and actual data can be compared, differences can be determined and the required measures can immediately be taken which in turn optimizes flexibility of processes.

Furthermore, with this system the procedures could be streamlined and laborious duplicate entries were no longer necessary. Previously the machine operator made a note of the data in order to enter them into an access database or an excel table at a later date. These were then taken from the database once a month by a secretary and transferred into the computer, "we now have a solution in which only one person has to record the data accordingly", emphasizes Berndt. That is, for example, also "a really successful action" for product traceability.

Exact preliminary and final costing improve cost transparency

An exact preliminary and final costing could also be realized; these days they form the basis for a substantially improved cost transparency. The IT partner, alltrotec GmbH from Dresden, performed additional programming for the preliminary costing in abas ERP so that it was exactly tailored to the needs and requirements of the company in Coswig. The preliminary costing is carried out on the basis of the series of operations recorded in the BOM and its materials. The final costing occurs on the basis of the recorded data. The materials are directly read from the process computer on the melting furnace. This is where the lots and the melting process are controlled. The industry PC generated a lot log of which material and how much of it is in the lot, then it allocates the production numbers and records both in Access. From there these data are transferred into the PDC database of abas ERP by the click of a button. "It works excellently", Sven Berndt expresses his satisfaction with the interface. Also, other individual queries and evaluations are mostly still carried out in Access. "Our users are used to working with this program", states Berndt. Because of this the compatibility to the Microsoft world was the main factor in the decision made by the company from Coswig. Bernd knows that the ERP system running using Linux fulfills these key qualifications. The combination of abas ERP and Linux is appraised by the Head of IT as "absolutely reliable, we have had no system crash since installation."

Approximately two years ago the real operation of abas Business Software began. Before this the new programs had been tested on a demo client. Bernd talks about the package and the good experiences from the previous 24 months: "It was the right decision." The reason for his high opinion is "the high degree of flexibility" - the 37 year old exemplifies that the business processes which are constantly changing can always be flexibly represented by ABAS. Berndt quotes the increase in revenue as an example: In 2004, the roller foundry gained an increase of 33 percent reaching EUR 24 million with almost the same amount of personel. Part of the increase in revenue is due to the new machines - however, it is also due to the investment in a modern software which put a business dynamic into gear and which optimized the processes.

Isolated applications which were previously common practice are passé because the abas Business Software can cover all business processes. Many employees had more or less put together their own databases which, however, did not support the business processes because not everyone in the company was able to access this information. In contrast, a continuous workflow could be achieved using the ERP solution. "Here a uniform database was created", says Berndt, "if one introduces such a system then naturally all should also be able to work with it."

Customers receive exact information on the production progress

For example, the material data which come out of the process computer at the melting furnace are immediately recorded and read-in to abas ERP which means that the information is available to the work schedulers close to realtime. The planners therefore always know exactly at which point the production process for each product is. "We have a much greater transparency of the internal production process", emphasizes the Head of IT. Thus, for example, the company can tell the customer exactly how far their product is in the completion and when it can be delivered. "This did not happen before to this degree." "The strategical goal was to optimize the cooperative work with customers and vendors,", says Berndt, "we were able to achieve this in this way."

If sales orders need to be changed at short notice or bottlenecks need to be controlled, "I always have my products and materials in view and can give exact information about them". Thus, the roller foundry is supported by the ERP system with cut delivery times and an improved adherence to delivery times.

Despite the fact that the company from Coswig is extremely pleased with the new ERP software, the efforts in the IT area are not yet over. For example, the efficiency of the external data access is to be increased for the external sales force and the topic of digital tax auditing (GDPdU) is to be pressed on with. The abas Business Software comes into play here also. It provides an archiving tool which collects the business relevant processes/transactions for the digital tax audit, e.g. Emails with requests, purchase orders or sales orders. "These are immediately accessible if the tax office asks for them", says Berndt.

Further planning shows: the abas Business Software will also be customized in the future to the requirements of the roller foundry. The conversion phase is not yet over in the company from Coswig. Despite this the ERP solution for the roller foundry has proven itself to be a hit, the experiences from the past two years have been very positive - even though there was resistance at times during the implementation period, for example from departments or employees within the company who wanted to keep their isolated applications. "Such isolated solutions could be more advantageous to individuals or a department than a general solution, but are always a stumbling block for optimizing the overall process", says Sven Berndt from experience. He made sure he had the support of the management for the implementation of such a department spanning ERP project. "This is absolutely essential and fortunately we have 100% backup."

***

Company profile of the ABAS Software AG

More than 1,700 customers have opted to use ABAS as their IT specialist and for the integrated abas Business Software, which has become one of the most successful ERP programs on the international market during the past few years. ABAS has as their customers top companies (with 10 to 1000 employees) from various business sectors. The list of references includes well-known companies such as Würth Elektronik, Dortmunder Westfalenhallen, Mafell, Robbe, Lufthansa LEOS and HOMA Pumpenfabrik. The ABAS Software AG has established a qualified partner network of over 450 IT organizational and application consultants for their customer support. The abas Software Partners provide on-site support and a range of services including implementation, hardware and network support, customization and a helpdesk.

Around 40 abas Software Partners ensure quick reaction times and a high quality service. International partners in Germany, Austria, Switzerland, the Netherlands, Hungary, Poland, Rumania, Bulgaria, Turkey, the Czech Republic, France, Spain, Italy, Saudi Arabia, Iran, Indonesia, Malaysia, China, Hong Kong, Australia, Latin America and the USA represent the ABAS Software AG throughout the world. The partner network is continuously expanded.

abas Business Software – product portrait

abas Business Software is a flexible, adaptable and future-proof complete business solution (ERP, PPC, MRP, eBusiness) for medium-sized businesses. The flexible ERP standard software optimizes the business processes in the company. Manifold optional web and eBusiness applications can be implemented. The clear structure and well thought-out implementation strategy of abas Business Software enables a short implementation period, as well as a trouble-free integration into the company structure. Specific requirements can be integrated into abas ERP at a minimal cost. New functions and technologies are constantly added to the standard software. As a result, abas users are always using the most up-to-date product. abas Business Software can run using Linux, Unix and Windows. ABAS has supported the open source operating system Linux on the server-side since 1995. Approximately 80% of over 1,700 abas installations are based on Linux. abas Business Software is offered in the front end range of Linux from Version 2003 onwards. Linux has proven to be a cost effective, stable and high performance system on both the server and the client side. The service spectrum includes: Sales/sales order processing/shipping, purchasing/purchase orders, warehouse management, scheduling, logistics, materials management/MRP, production/PPC, financial accounting, fixed asset accounting, cost accounting, controlling, eBusiness, etc.

ABAS Software AG

Suedendstr. 42

76135 Karlsruhe

GERMANY

Tel. +49 721-9672301

Fax +49 721-679651

info@abas.de

www.abas.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Walzengießerei Coswig improves hitting deadlines and increases cost transparency using abas ERP here

News-ID: 3018 • Views: …

More Releases from ABAS Software AG

Managing Trust @ CeBIT 2012 with ABAS

Experiencing abas Business Suite (ERP, DMS, BI, Mobile Solutions) in hall 5, stand C18

Karlsruhe, Germany, January 19, 2012 - From March 6th to 10th, 2012, ABAS Software AG and its software partners from around the world will demonstrate abas Business Suite (ERP, DMS, BI, Mobile Solutions), the complete package for midsize companies, in hall 5, stand C18.

ABAS, the company you can trust!

Trust is essential to every business. So, implementing an…

ABAS Software AG supports European Automotive Project

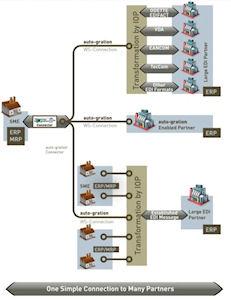

With “Auto-gration”, ABAS Software AG supports SME’s in the supply chain sector

Karlsruhe, Germany, January 19, 2012 – ABAS Software AG announces that the company will support the project “Auto-gration”, led by the European Commission. Goal of the project is to integrate small and medium enterprises into the automotive digital supply chain.

Enhancing the integration of SME’s

By supporting Auto-gration, ABAS is partnering with their clients to run pilot projects. The…

American Conveyor implements abas Business Software to “manage costs and impro …

A completely integrated and comprehensive ERP system

Karlsruhe, Germany / Sterling, VA, January 19, 2012 - abas-USA announced that American Conveyor has chosen abas Business Software as its enterprise software for the future.

abas Business Software provides real time visibility to all aspects of the business

Dave Freemen, President of American Conveyor, said, “As a small company, American Conveyor had specific requirements of a completely integrated and comprehensive ERP system. We also…

abas ERP: increased value with every new version

abas Business Software‘s evolutionary upgrade path means continual seemless upgrades without reimplementation

Karlsruhe, January 18, 2012 - Many innovations in the current abas Business Software version make daily work with the ERP system even more efficient and easy. For example, using the portal application, the purchasing and sales employee can now bundle the most important role-based information on one screen.

Further actions or analysis can be executed directly from the screen. Mobile…

More Releases for ERP

Casting ERP Software - Top Foundry ERP Software Solutions by CBS Software Soluti …

The metal casting and foundry industry is one of the most complex segments of manufacturing. From raw material procurement and melt planning to production scheduling, quality control, and dispatch, every stage demands precision, traceability, and cost efficiency. Traditional manual processes and generic ERP systems often fail to address these industry-specific challenges. This is where Casting ERP Software and Foundry ERP Software play a crucial role.

A purpose-built Casting ERP system helps…

Medical Resource Management ERP Market Is Booming Worldwide | Major Giants GHX, …

HTF MI just released the Global Medical Resource Management ERP Market Study, a comprehensive analysis of the market that spans more than 143+ pages and describes the product and industry scope as well as the market prognosis and status for 2025-2032. The marketization process is being accelerated by the market study's segmentation by important regions. The market is currently expanding its reach.

Key Players in This Report Include:

SAP Ariba Healthcare, Oracle…

ERP Linker Unveils Next-Gen ERP Integration for E-Commerce Growth

ERP Linker, a recognized innovator in ERP automation and e-commerce integration, announces the launch of its advanced integration suite designed to enable seamless synchronization between leading ERP platforms-such as SAP, NetSuite, Oracle, SYSPRO, and Plex-and top e-commerce engines including Shopify, BigCommerce, and WooCommerce.

Modern businesses are confronted with the challenge of maintaining operational efficiency and data accuracy across multiple systems. ERP Linker's unique solution addresses this by transforming complex ERP logic…

Healthcare ERP Market - Simplify, Optimize, Excel: Empowering Healthcare with ER …

Newark, New Castle, USA: The "Healthcare ERP Market" provides a value chain analysis of revenue for the anticipated period from 2023 to 2031. The report will include a full and comprehensive analysis of the business operations of all market leaders in this industry, as well as their in-depth market research, historical market development, and information about their market competitors.

Healthcare ERP Market: https://www.growthplusreports.com/report/healthcare-erp-market/8453

This latest report researches the industry structure, sales, revenue,…

ERP Integration with Big Data to Fuel ERP Market's Growth

Triton Market Research presents the Global Enterprise Resource Planning Market report segmented by Application (Supply Chain, Inventory Management, Finance, Customer Management, Human Resource (HR), Manufacturing Module, Other Applications), Enterprise Size (Small Enterprises, Large Enterprises, Medium Enterprises), Verticals (IT and Telecom, Retail, Banking, Financial Services, & Insurance (BFSI), Manufacturing, Military and Defense, Government, Healthcare, Other Verticals), and by Geography (Europe, Middle East and Africa, Latin America, Asia-Pacific, North America). The report…

Best ERP Software in India | Cloud Based ERP Software in India

ERP software systems are the best software systems that prove to be of great help in operations planning, administration and to optimize Internal Business Processes, Comprising of Manufacturing, Supply Chain, Finance, CRM, Human Resources as well as warehouse management. With the help of these solutions, a typical ERP software integrates the data and processes of an organization into a single unified system.

Tech Cloud ERP Software Solutions offer the best ERP…