Press release

Economic Cutting of Metal Tubes – from Aluminium to Titan

Berg/Germany, 11-26-2014Without metal tubes cut to a specified length – out of various metallic materials – many products cannot fulfil their proper functions. Thus an optimized and economic handling of the tubes before and during the cutting process is particularly important.

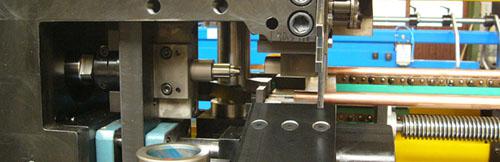

The German company Weerth Handling Systeme GmbH, Berg/Baden-Württember, has specialised from its foundation in 1986 on the chipless cutting and machined end conditioning of all kinds of tubes, up to 76 mm, as well as on storing and feeding equipment for tubes.

Based on its patent dating back to the 1980‘s Weerth developed a range of machines and plants for the chipless cutting process of metallic tubes.

They supply solutions from manually fed machines to machinery configurations that can be incorporated into existing production processes – always configured as per the needs of the specific client.

After cutting and/or end conditioning of the tubes they can be automatically stored via a specific system and later be supplied to a pre-defined other production step.

Due to the systems developed not only a significant material saving is realized – the loss of material in normal cutting processes by saws ranges between 2 and 3 mm/cut – but also additional production steps (like the following washing, deburring, etc.) can be deleted completely.

The tubes leave the machines clean and without major burrs, and the minimal diameter reduction during the cutting process allows – in the majority of cases – for a direct insertion of a mandrel, if needed, without reworking the section cut.

A permanent improvement of the machines is realized by the ongoing answering of new/advanced requirements by existing and new clients and thus a continuous development is guaranteed.

World-famous international companies – please also see the reference list on the website – e. g. from BMW to FESTO, or Volkswagen to PFW Aerospace, and others, trust in the well-engineered systems of Weerth, and use them as well in their German main plants as in foreign subsidiaries.

Additionally to the classical cutting of metal tubes – e. g. for the automotive, heating, air conditioning, ventilation, solar as well as furniture industries – a variety of fields of application is possible - like e. g. for battery clamps or hydraulic lines. Each and every task or client need is tested with regards to an economic application of the system.

Author:

Michael Richter, International Marketing- and Sales Consultant, offers, based on more than 40 years practical experience in strategic marketing in/to all 5 continents, assistance and/or training in internationalizing – from market research and marketing planning to implementation of the consultancy results – in Europe or worldwide. Country experience please see http://www.internationales-marketingkonzept.de/en/country_information/index.html

In addition he offers internal marketing seminars, especially orientated at the needs of the client companies.

Weerth Handling Syteme GmbH, Berg/Germany, is specialised in supplying chipless cutting systems for metalt ubes of all kinds.

Weerth-Handling-Systeme GmbH

Bachstrasse 10

88276 Berg-Weiler

http://www.weerth.com

info@weerth.com

Tel.: 0751-3629930

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Economic Cutting of Metal Tubes – from Aluminium to Titan here

News-ID: 300304 • Views: …

More Releases from Michael Richter - International marketing and sales consultant

Material-saving Cutting and Treatment of Metal Tubes

Berg/Germany, 18. 6. 2014

Metal tubes – from aluminum to titanium – are essential elements of many products. Consequently a material-saving and exact cutting of the basic material material combined with a directly linked further treatment results in cost savings and thus an increase of earnings.

Basing on own patents the chipless and low-burr cutting system of Weerth Handling Systeme Gmbh, Berg/Germany, including the special ‚tear-break‘-system, built-up its national…

Metal tubes: Handling and Processing by Systems of Weerth Handling-Systeme GmbH

Seekirch 11.2.2014

Update: Many industries need metal tubes cut to exact lengths (millimeters) for their products - out of many metals and alloys. Especially adapted and extremely economical working systems are supplied by Weerth Handling Systeme (WHS), Germany/Baden-Württemberg. The system advantages are considerable.

WHS is one of the first manufacturers worldwide, producing innovative machinery and plant for the chipless and low-burr-cutting of metal tubes, including the self-developed, patented, tear/break-system. WHS is a…

More Releases for Weerth

Material-saving Cutting and Treatment of Metal Tubes

Berg/Germany, 18. 6. 2014

Metal tubes – from aluminum to titanium – are essential elements of many products. Consequently a material-saving and exact cutting of the basic material material combined with a directly linked further treatment results in cost savings and thus an increase of earnings.

Basing on own patents the chipless and low-burr cutting system of Weerth Handling Systeme Gmbh, Berg/Germany, including the special ‚tear-break‘-system, built-up its national…

Metal tubes: Handling and Processing by Systems of Weerth Handling-Systeme GmbH

Seekirch 11.2.2014

Update: Many industries need metal tubes cut to exact lengths (millimeters) for their products - out of many metals and alloys. Especially adapted and extremely economical working systems are supplied by Weerth Handling Systeme (WHS), Germany/Baden-Württemberg. The system advantages are considerable.

WHS is one of the first manufacturers worldwide, producing innovative machinery and plant for the chipless and low-burr-cutting of metal tubes, including the self-developed, patented, tear/break-system. WHS is a…

Fast – Clean – Economical: Cutting metal tubes – from steel to titanium, u …

Seekirch, October 12, 2012

Metal tubes – out of various materials – are absolutely necessary in many modern products, despite numerous substitutions. Therefore it is wise to treat them material friendly as well as to minimize material loss in cutting processes..

Weerth-Handling-Systeme GmbH, Berg/Germany, have specialized in cutting and end forming of metal tubes up to a diameter of 76 mm, as well as in storing and feeding tubes for a…

Industrial tube and pipe processing – new website

Whatever the technical progress is: Without tubes and pipes of various metals and alloys a multitude of products is nearly unthinkable – from radiators, to cars or refrigerators, various machinery, solar plants, and more …

This is the speciality – for more than 20 years now – of Weerth-Handling-Systeme, Berg/Germany, one of the typical European ingenious SME’s.

The machinery developed and produced by Weerth – from the automatic or manual tube…