Press release

DIENES develops 4-fold simultaneous core cutter for three different core diameters

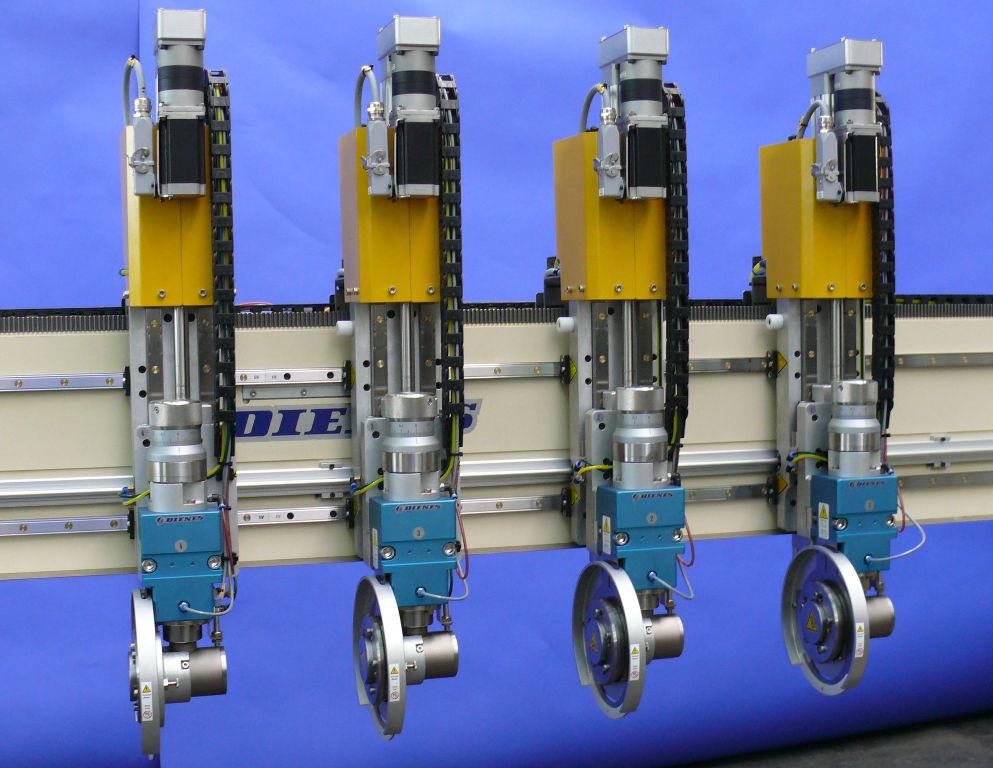

With four times higher speed, efficient flexibility and high service life – the new core cutter from DIENES is a trendsetting solution to support individual processes in the cutting of cores for the rewinding of different materials, e. g. paper, film or foilDIENES is the worldwide leading manufacturer and turnkey provider of industrial slitting tools as well as solution-oriented slitting systems, which live up to nationally and internationally expectations. One of the most recent innovations from DIENES in the area of slitting systems is a 4-fold simultaneous core cutter, which was developed for the processing of cores in the hygiene industry. Based on its outstanding flexibility and capacity the system can also be used for the manufacturing of cores in other industries, e. g. paper, film or foil.

Individual targets require individual developments

The development of the 4-fold simultaneous core cutter was carried out on customer specific order to cut cardboard cores with three different diameters – in this case 75, 150 and 170 mm – as well as a minimum core width of 5 mm (at an initial state of the core unit of 3.800 mm width). The core cutting unit was to be integrated in an existing slitter-rewinder and replaced the previous core cutter – which only had one slitting unit – because this unit slowed down the whole process. A retrofit of this unit therefore was economical sensible to achieve a higher slitting speed as well as an improved cutting quality.

The DIENES in-house development team met the high customer demands and developed a 4-fold simultaneous core cutter with four efficient cutting units, each consisting of a core cutting knife holder and a corresponding linear adapter. The four slitting units contribute significantly to the increased speed for the core cutting process. Especially in comparison to the slitting unit (1) used previously. In addition the slitting units – each equipped with a motor – are simultaneously and independently adjustable. The complete control of the system is done via a user friendly and safe touch panel outside the slitting area. The required information for the cutting, such as number and width of the cores, receives the system directly from the control panel of the slitting system, which is cutting the material to be rewound. It transfers the slid width to the core cutter, which calculates the “slitting recipe” subsequently, meaning the corresponding core width and if necessary the spacers between the actual cores. These spacers grant a fault-free winding of the material in the following process. Additionally, the system provides a positioning accuracy of +/- 0,15 mm.

Furthermore the slitting pressure applied to the knife holder can be adjusted with the control panel. It is possible to work with two different pressures during the slitting process. The lower pressure is used to generate a groove in the material. The higher pressure completes the cut. Thus the cutting of a spiral is avoided – especially with thick material. If requested it is possible to block and park individual slitting units within the system. The chosen slitting recipe will then be carried out only by the active units.

Thought out down to the smallest detail

The integrated linear adapter has two basic functions: first, the mounting of the knife holder and second, its movement to the desired position in the system. In addition this adapter impresses with its electrically movable vertical stroke (approx. 120 mm), which allows the quick vertical adjustment to different core diameters. In this case these diameters were 75, 150 and 170 mm. But the system is also realizable with other individual requirements concerning the core diameters.

The used knife holder type DS 8 in core cutting design belongs to the most recent knife holder generation developed by DIENES and is also well thought out and innovative. Beside its stability and corrosion resistance the DS 8 impresses with a wide range of safety features, such as our 360° hand guard as well as a locking pin and bayonet knife fixing. This makes the knife exchange safer and easier for the machine operator without increasing the setup time. After the basic adjustment the exact electrical setting of the immersion depth results in a lower knife wear. If regrinding is required the immersion depth can easily be readjusted via the control panel. Furthermore the knife holder has two separate vertical stroke compressed air connections. The first connection is responsible for the downward movement of the knife holder into the material, the second one for actively releasing the knife holder from the material.

Benefits of our 4-fold simultaneous core cutter at a glance

- Speed of the core cutting

- Four times higher speed as the previous solutions and therefore a more economical production

- Flexibility with three different core diameters and small / varying slit widths

- Improved cutting quality

- User friendly operation with secure touch-panel

- Higher service-life due to less knife wear

For questions about our 4-fold simultaneous core cutter or all other DIENES products please contact our sales team +49 (0) 2206 605-0 or via e-mail sales@dienes.de

Please also visit our website www.dienes.de for more information.

In 1913 the company was established by Karl Rudolf Dienes in Remscheid, Germany, and can now look back on more than 100 successful years, several international locations as well as numerous pioneering innovations and patents. Today, the owner-managed traditional company has its company headquarters in Overath near Cologne in Germany and provides more than ever integrated and innovative solutions in the fields of knives, knife holders, slitting systems and valves.

DIENES Werke für Maschinenteile GmbH & Co. KG

Koelner Strasse 7

51491 Overath

Press contact

Petra Boehme

Marketing

E-Mail: presse@dienes.de

Telefon: +49 2206 605-0

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release DIENES develops 4-fold simultaneous core cutter for three different core diameters here

News-ID: 284377 • Views: …

More Releases from Dienes Werke für Maschinenteile GmbH & Co. KG

DIENES knife holder DS µ receives the C2 European Innovation Award 2013

High precision and with optimum functionality: The knife holder DS µ from DIENES, the worldwide leading manufacturer and turnkey provider of industrial slitting tools, adjusts to the user’s highest demands in the field of high-tech foils, such as battery foil. This innovative, market influencing development of DIENES received recently the C2 European Innovation Award 2013 and the C2 American Innovation Award.

Thanks to 100 years of experience DIENES knows exactly what…

More Releases for Germany

Robot End Effector Market Size in 2023 To 2029 | Schunk (Germany), Schmalz (Germ …

The report offers a detailed measurement of the drivers, development, and prospects that have a direct impact on the Robot End Effector market. The market study contains an in-depth analysis of the international Robot End Effector Market based on the key boundaries that encompass the drivers, sales inquiry, market limits & share. The report further highlights assessing the market size of four key regions, namely North America, Europe, Asia-Pacific, and…

Germany Agriculture Market, Germany Agriculture Industry, Germany Agriculture Da …

Agriculture is important sector for the Germany’s food security and also a provider of jobs. More than half of country’s national territory is used for farming. Approximately 1 million people currently work part-time or full-time in agricultural holdings. Key agricultural products include milk, cereals, potatoes, barley, cabbages, pork, beef, poultry, wheat, and sugar beets. In some regions fruits & vegetables, wine and other horticultural products play a significant role. Agricultural…

High Voltage System Market 2020: Top Key Players Are Bosch (Germany), Continenta …

High Voltage System Market Overview:

Research report on The High Voltage System Market by ‘Market Growth Insight’ covers deep analysis on key factors that directly influence the market growth including impact of COVID-19. The report is a thorough study of drivers, opportunities, restraints, challenges, and risks associated with the High Voltage System market to help the players plan their growth activities and strategies carefully, while considering these crucial factors. The High…

Product Engineering Services Market Outlook 2024 By Key Players: Accenture PLC(G …

Product Engineering Services Market reports report offers a comprehensive evaluation of the global market analysis (2019-2024). This 94 pages research study involves the extensive use of both primary interviews and secondary research data sources. The report consists of market share, size, CAGR, industry analysis, go to market strategy, SWOT analysis, sales, revenue, key players, information on products and application, competitive insights, value chain, and macroeconomic analysis etc.

The product engineering is…

High Voltage System Market Scenario Highlighting Major Drivers & Trends, 2019 � …

High Voltage System Industry research report delivers a close watch on leading competitors with strategic analysis, micro and macro market trend and scenarios, pricing analysis and a holistic overview of the market situations in the forecast period. It is a professional and a detailed report focusing on primary and secondary drivers, market share, leading segments and geographical analysis. Further, key players, major collaborations, merger & acquisitions along with trending innovation…

Global Contrast Sensor Market 2025 | BALLUFF(Germany), CONTRINEX(Swizerland), Di …

Researchmoz added Most up-to-date research on "Global Contrast Sensor Market Insights, Forecast to 2025" to its huge collection of research reports.

The Contrast Sensor market was valued at Million US$ in 2017 and is projected to reach Million US$ by 2025, at a CAGR of during the forecast period. In this study, 2017 has been considered as the base year and 2018 to 2025 as the forecast period to estimate the…