Press release

Submerged Arc Welding - the Most Practical Steel Pipe Welding Technology

Submerged arc welding (SAW) is one of the most efficient mechanized welding methods today. Its full name is automatic submerged arc welding, also known as automatic arc welding under the flux layer.Submerged arc welding technology is ideal for important applications such as pipelines, pressure vessels and storage tanks, rail manufacturing and large-scale construction. Available in the simplest form of single wire, double wire construction , series double-filament structure, multi-filament structure.

Submerged arc welding technology can benefit users in many welding applications. From increasing productivity to improving the working environment to ensuring consistent quality and more. Metal fabricators who are considering making changes to the submerged arc welding process should be thinking that there are many benefits to be gained from the process.

Advantages of submerged arc welding:

Submerged arc welding (SAW) technology is suitable for heavy industrial applications such as pipelines, pressure vessels and storage tanks, locomotive construction and heavy construction/excavation. Ideal for industries requiring high productivity, especially welding involving very thick materials, many benefits can be derived from the submerged arc welding process. Its high deposition rate and travel speed can have a significant impact on worker productivity, efficiency and production costs, which is one of the key advantages of submerged arc welding technology.

Other benefits include excellent weld chemistry and mechanical properties, minimal arc visibility and lower welding fumes, improved comfort in the work environment, and good weld shape and toe line.

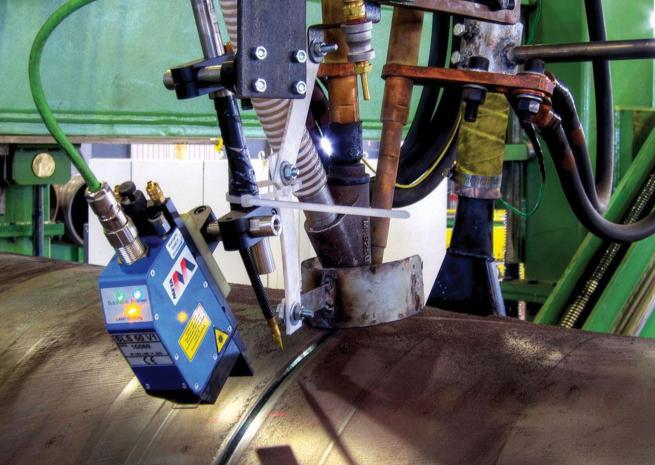

Submerged arc welding is a wire feeder that uses a granular flux to separate the arc from the air. As the name suggests, the arc is buried in the flux, which means that when the parameters are set, the arc is invisible as the next layer of flux flows out. Welding wire is continuously fed by a torch that moves along the weld. Arc heating melts a section of welding wire, part of the flux and base metal to form a molten pool, which condenses to form a weld covered with a layer of slag. Welding material thicknesses vary from 1/16" to 3/4", and single pass welds can be welded with 100% penetration. If the wall thickness is not limited, multi-pass welding is possible, the weld should be properly pre-treated, and the appropriate combination of welding wire and flux should be selected.

High quality of welding seam: The slag has good protection effect of air isolation, welding parameters can be kept stable through automatic adjustment, the technical level of the welder is not high, the welding seam composition is stable, and the mechanical properties are relatively good.

Good labor conditions: In addition to reducing the labor intensity of manual welding operations, it has no arc radiation, which is a unique advantage of submerged arc welding.

Submerged arc welding application range:

At present, it is mainly used for welding various steel plate structures. Weldable steel types include carbon structural steel, stainless steel, heat-resistant steel and its composite steel. Submerged arc welding is most widely used in shipbuilding, boilers, chemical containers, bridges, lifting machinery, metallurgical machinery manufacturing, marine structures, and nuclear power equipment. In addition, submerged arc welding is used for surfacing wear-resistant and corrosion-resistant alloys or for welding nickel-based alloys, copper alloys are also ideal.

Permanent Steel Manufacturing Co.,Ltd: https://www.permanentsteel.com

Address: #668,Lugu Avenue,Hi-Tech Industrial Development Zone,Changsha,China

Postcode:410205

Tel:0086-731-88787784

Fax:0086-731-89878292

E-mail: sales@permanentsteel.com

LSAW steel pipe: https://www.permanentsteel.com/productshow/lsaw-steel-pipe.html

SSAW steel pipe: https://www.permanentsteel.com/productshow/ssaw-steel-pipe.html

Seamless steel pipe: https://www.permanentsteel.com/product/carbon-steel-pipe.html

ERW steel pipe: https://www.permanentsteel.com/productshow/erw-steel-pipe.html

LinkedIn: https://www.linkedin.com/company/permanent-steel-manufacturing-co-ltd/

Permanent Steel Manufacturing Co.,Ltd is a professional manufacturer & exporter of steel pipes in China. Products including carbon steel pipe(SMLS pipe/ERW/LSAW/SSAW),stainless steel pipe,galvanized steel pipe,alloy steel pipe and the related products.We offer perfect service to our customers and bring in the highest quality steel pipes at the most competitive price for our Clients. Our entire operations are focused on the precise demands of our client needs.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Submerged Arc Welding - the Most Practical Steel Pipe Welding Technology here

News-ID: 2733518 • Views: …

More Releases from Permanent Steel Manufacturing Co.,Ltd

Seamless Pipes for Energy Equipment

Seamless pipes play an extremely important role in energy equipment, especially in systems that need to withstand harsh working conditions such as high temperature, high pressure, and corrosion. Since there are no welded seams in its manufacturing process, seamless steel pipe has higher structural integrity, uniform mechanical properties and excellent pressure bearing capacity, making it the preferred piping material in the energy sector. Permanent Steel Manufacturing Co., Ltd. has carefully…

Can Galvanized Steel Pipes be Painted?

Galvanized steel pipe is a common metal pipe, which is widely used in construction, water supply, HVAC and other fields due to its excellent anti-corrosion performance. However, with the diversification of usage scenarios, many people have begun to consider painting galvanized steel pipes to improve their aesthetics or further enhance their protective effect.

Basic characteristics of galvanized steel pipe

Galvanized pipes are metal pipes made by coating the surface of ordinary…

How to Remove Weld Spots from 304 Stainless Steel Pipes?

Welded pipes are made by welding, and the welds of 304 stainless steel pipes will leave more or less orange, blue, and black weld spots after welding, which are very difficult to remove. The presence of weld spots not only affects the appearance, but also accelerates corrosion in the atmosphere, reduces corrosion resistance, and has a certain impact on use. So, how to remove weld spots on 304 stainless steel…

How to Store Stainless Steel Elbows?

Stainless steel elbows are elbows made of stainless steel. The Stainless steel elbow is a kind of elbow fittings. Because of the material, they can remain rust-free and non-corrosive for a long time, so they are more reliable to use. And the service life is longer than that of iron, so many people now choose to use stainless steel elbows. Then after we buy the stainless steel elbow, its storage…

More Releases for Submerged

Ehong Steel - LSAW (Longitudinal Submerged Arc Welding) Pipe

LSAW PIPE [https://www.ehongsteel.com/manufacturer-price-fusion-bonded-epoxy-fbe-coating-pipe-lsaw-ssaw-erw-mild-steel-pipe-for-underground-pipeline-product/]- Longitudinal Submerged Arc Welded Steel PipeIntroduction:It is a long welded submerged arc welded pipe, usually used to transport liquid or gas. The production process of LSAW pipes involves bending steel plates into tubular shapes and then performing submerged arc welding to form long welded pipes.

Image: https://www.ehongsteel.com/uploads/IMG_6680.jpgImage: https://www.ehongsteel.com/uploads/IMG_6625.jpgImage: https://www.ehongsteel.com/uploads/IMG_3712.jpgImage: https://www.ehongsteel.com/uploads/lsaw-pipe-size.jpgImage: https://www.ehongsteel.com/uploads/lsaw-pipe-package.jpg

Standard: GB/T 3091

Steel Grade: Q235(Q235A Q235B Q235C Q235D) Q345(Q345A Q345B Q345C Q345D)

API 5L: Gr.A Gr.B X52 X60 X72

Image:…

Submerged in Innovation: Cryogenic Submerged Motor Pumps Arrive | Nikkiso Cryo, …

Cryogenic Submerged Motor Pumps Market 2023 Forecast: Unveiling Opportunities and Growth

Cryogenic Submerged Motor Pumps market report presents an overview of the market on the basis of key parameters such as market size, revenue, sales analysis and key drivers. The market size of global Cryogenic Submerged Motor Pumps market is anticipated to grow at large scale over the forecast period (2023-2029). The main purpose of the study report is to give…

Submerged Arc Welders Market Size, Share, Development by 2024

Global Info Research offers a latest published report on Submerged Arc Welders Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. This report focuses on the key global Submerged Arc Welders players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Submerged Arc Welders with respect…

Global Submerged Arc Welding Machine Market Insights, Forecast to 2025

Market Research Report Store offers a latest published report on Submerged Arc Welding Machine Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report.

This report focuses on the key global Submerged Arc Welding Machine players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Submerged Arc Welding…

Submerged Spiral Classifier Market: Competitive Dynamics & Global Outlook 2023

New report published by Global Info Research which offers insights on the global Submerged Spiral Classifier market.

Submerged spiral classifier with the spiral of overflow end completely immersed below liquid level is applied in classifying ore with particle size 0.15~0.07mm.Spiral classifier is widely used in closed circuit ball mill for grading ore, sliting gravity plant, grading granularity, ore beneficiation and dewatering. There are two types of spiral classifier, single spiral classifier…

Submerged Arc Welding Market Size, Share, Development by 2023

New report published by Global Info Research which offers insights on the global Submerged Arc Welding market.

Submerged arc welding involves the formation of an arc on a continuously fed bare wire electrode and the desired workpiece. The process makes use of a granular flux to produce protective gases, slag, and to add alloying elements to the weld pool.

Click to view the full report TOC, figure…