Press release

Flexographic Printing Inks Market Expected to Expand at a Steady CAGR of 4% through 2031

Global Flexographic Printing Inks Market IntroductionFlexographic printing offers several advantages over traditional lithographic printing presses. It has a shorter startup time and can print using a wide variety of inks on almost any substrate. Popularity of flexographic printing is rising due to its speed, cost-effectiveness, and reduced toll on the environment.

Read report Overview:

https://www.transparencymarketresearch.com/flexographic-printing-inks.html

Application of ink is the most important part of the printing process. Flexographic printing has extremely high press speeds and is suited for long runs - a good consideration for medium to large print jobs that need to be completed as quickly as possible. Flexographic ink is available in three major varieties: water-based, UV curable, and solvent-based. The substrate type - or printing surface - ultimately dictates the ink that is likely to be used for each application. Solvent-based inks are less popular due to their harmful impact on the environment, despite the fact that they are safe for usage in food packaging and other household applications.

Flexographic inks are primarily used in the process of flexography to print ink on materials such as plastic bags, newspapers, catalogs, food packaging, corrugated cardboard, cardboard boxes, and other types of packing mediums. Flexographic printing ink offers superior adhesion to non-porous surfaces such as metals, glass, polypropylene, and vinyl while maintaining excellent press open time and notable alkali resistance. Thus, rise in application of flexographic printing inks is anticipated to drive the market during the forecast period.

Request For Sample :

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=2329

High Demand for Flexographic Printing Inks in Food Packaging Industry to Propel Global Market

Flexography is a modern version of letterpress printing. This traditional method of printing can be used on almost any type of substrate including corrugated cardboard, cellophane, plastic, label stock, fabric, and metallic film. The flexographic printing process employs quick-drying, semiliquid inks. In this age of digital printing, flexography is preferred for large orders and long print runs, particularly for packaging products and labeling. Flexographic printing uses non-toxic inks and has a quick drying time. This printing method is extensively employed for the printing of bold designs, and extremely attractive effects can be achieved using 3 to 45 colors.

This makes flexographic inks beneficial in the printing of food packaging. These inks can be used on the packaging of food products such as milk cartons, beverage containers, food containers, as well as disposable cups and containers. Therefore, high demand for flexographic printing inks in the food packaging industry is expected to drive the market.

Request for Customization :

https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=2329

Rise in Preference for Polyurethane Resin-based Inks

Rise in popularity of the flexible packaging format can be ascribed to the numerous benefits it offers over existing alternatives. It offers advantages such as extended shelf-life, lower transportation costs, and reduced material consumption and landfill contribution. This format is cost-effective and provides an ideal marketing opportunity with the ability to print on flexible packaging substrates. Enabling these benefits are continual improvements in substrate, ink, printing, and converting technology. One of the major areas of attention for flexo ink is resins. Various types of resins go into inks that are used for printing on flexible packaging such as styrene acrylics, polyurethanes, polyamides, and nitrocellulose. Unique requirements and challenges of such packaging are driving the preference for polyurethane resin-based ink systems.

Polyurethane resins are used in flexographic and gravure universal laminating ink systems, as they provide specific features such as direct pigment gridding, excellent adhesion, low odor/solvent retention, no yellowing performance, excellent anti-blocking, heat and water resistance, and high solid content. Therefore, increase in demand for polyurethane resins in flexographic printing is projected to drive the flexographic printing inks market.

Superior Print Quality and Good Adhesion Make UV-cured Inks Suitable for Various Printing Applications

In terms of type, the global flexographic printing inks market has been classified into water-based inks, solvent-based inks, and UV-cured inks. The UV-cured inks type segment held prominent share of 38.3% of the market in 2021. The segment is anticipated to grow at a CAGR of 3.5% by 2031. UV-cured inks offer superior print quality with no solvent replenishment and rapid readiness for use, good adhesion on flexible and many other substrates, high chemical and product resistance, and high running speeds. This also means that UV-cured inks are currently being considered in numerous printing areas.

UV curing flexo inks are being used for printing on nearly all the ranges of substrates used for finished products such as yogurt tops and cups, sugar, soup and spice sachets, flexible packaging, milk and juice cartons, pet food packaging, and even cigarette packs. Therefore, the UV-cured ink segment is expected to dominate the flexographic printing inks market during the forecast period.

Enquiry Before Buying:

https://www.transparencymarketresearch.com/sample/sample.php?flag=EB&rep_id=2329

Regional Outlook of Global Flexographic Printing Inks Market

In terms of region, Asia Pacific accounted for major share of the global flexographic printing inks market in 2021. Its share is expected to increase by 2031 due to large-scale production activities that take place in the region. Development in the industrial sector in China and India is projected to boost the usage of flexographic inks in Asia Pacific in the next few years. Growth of the flexographic printing inks market in Asia Pacific can also be ascribed to the increase in demand for flexographic printing inks in consumer goods packaging applications.

North America and Europe, cumulatively, held more than 50% share of the global market in 2021. Companies in these regions are renowned for developing new types of flexographic printing inks through research and development activities. Middle East & Africa and Latin America, cumulatively, accounted for about 10.0% share of the global flexographic printing inks market in 2021, owing to the presence of a large number of under-developed countries, such as Angola, Peru, and Sudan, in these regions.

Analysis of Key Players in Global Flexographic Printing Inks Market

The global flexographic printing inks market is highly consolidated, with a small number of large-scale vendors controlling the majority of the share. Most companies are investing significantly in comprehensive research and development activities, primarily to create environment-friendly products. Expansion of product portfolios and mergers and acquisitions are key strategies adopted by prominent players, which include Sun Chemical Corporation, Flint Group, Siegwerk Druckfarben AG & Co. KGaA, Toyo Ink SC Holdings Co., Ltd., and ALTANA AG.

Key Developments in Global Flexographic Printing Inks Market

On June 30, 2022, INX International Ink Co. delivered performance, efficiency, and sustainability to the shrink sleeve market with new ink products. INX International Ink Co. continues to cater to the market demand with innovative new ink products, as shrink sleeves gain more traction in the packaging arena. The latest development is INXFlex Contour, a dynamic UV and LED dual cure flexographic ink system designed to help produce distinctive shrink sleeve label solutions for brand owners.

On May 24, 2022, Siegwerk launched a new generation of NC inks manufactured at its fully automated production facility. The new generation of Siegwerk NC inks is currently the first series for flexible packaging printing that is manufactured at this site. Siegwerk is currently offering a new generation of water-based inks for flexographic printing in flexible packaging applications. These inks are produced with the state-of-the-art production equipment at the company's headquarters in Germany.

On August 18, 2020, Flint Group presented a quality evolution in flexographic printing. The print job was done with only six process colors - Cyan, Magenta, Yellow, Black, Green, and Violet - in the Flint Group supplied FlexiPrint MV, a next-generation NC-based ink system for high-performance surface print and lamination work.

The ink series offers maximized color strength and specific shades to support the highest quality and fixed pallet multi-color process work (high definition flexo).

Each of these players has been profiled in the flexographic printing inks market report based on parameters such as company overview, financial overview, business strategies, product portfolio, business segments, and recent developments.

Get Trending Report:

Waterproofing Membranes Market

https://www.transparencymarketresearch.com/waterproofing-membrane-market.html

Medical Plastics Market

https://www.transparencymarketresearch.com/medical-plastics-market.html

Adjuvants Market

https://www.transparencymarketresearch.com/adjuvants-market.html

Carbon Fiber Market

https://www.transparencymarketresearch.com/car

bon-fiber-market.html

Ferroalloys Market

https://www.transparencymarketresearch.com/ferroalloy-market.html

About Us

Transparency Market Research is a market intelligence company, providing business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants, use proprietary data sources and various tools and techniques to gather, and analyze information.Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact

Rohit Bhisey

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Email: sales@transparencymarketresearch.com

Website: https://www.transparencymarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Flexographic Printing Inks Market Expected to Expand at a Steady CAGR of 4% through 2031 here

News-ID: 2690027 • Views: …

More Releases from Transparency Market Research

Power Lawn and Garden Equipment Market Size Forecast to USD 188.4 Billion by 203 …

Power Lawn and Garden Equipment Market Outlook 2036

The global power lawn and garden equipment market was valued at US$ 93.9 Billion in 2025 and is projected to reach US$ 188.4 Billion by 2036, expanding at a steady CAGR of 6.6% from 2026 to 2036. Market growth is driven by increasing residential landscaping activities, rising demand for battery-powered equipment, expanding commercial landscaping services, and growing consumer interest in outdoor aesthetics.

👉 Get…

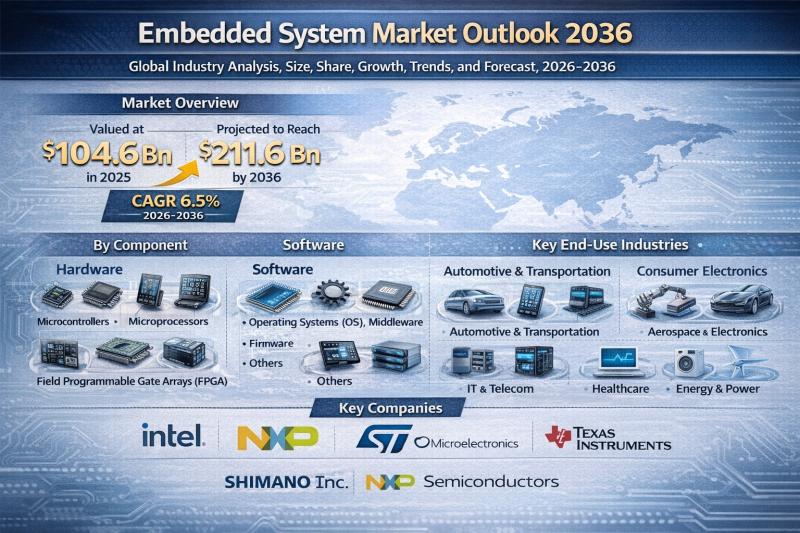

Global Embedded System Market to Reach USD 211.6 Bn by 2036, Expanding at 6.5% C …

The global embedded system market is poised for steady and sustained growth over the next decade, driven by rapid digital transformation across industries. Valued at US$ 104.6 Bn in 2025, the market is projected to reach US$ 211.6 Bn by 2036, expanding at a CAGR of 6.5% from 2026 to 2036. The increasing integration of embedded systems in automotive electronics, industrial automation, and IoT-enabled devices is positioning the industry as…

Industrial Fasteners Market Outlook 2036: Global Industry to Reach US$ 146.5 Bil …

The global industrial fasteners market was valued at US$ 104.6 Bn in 2025 and is projected to reach US$ 146.5 Bn by 2036, expanding at a steady CAGR of 3.1% from 2026 to 2036. The industry reflects consistent, volume-driven growth supported by expanding construction activities, infrastructure modernization, automotive production, and aerospace engineering advancements.

Between 2021 and 2024, the market demonstrated stable recovery post-pandemic, driven by revived industrial production and capital investments…

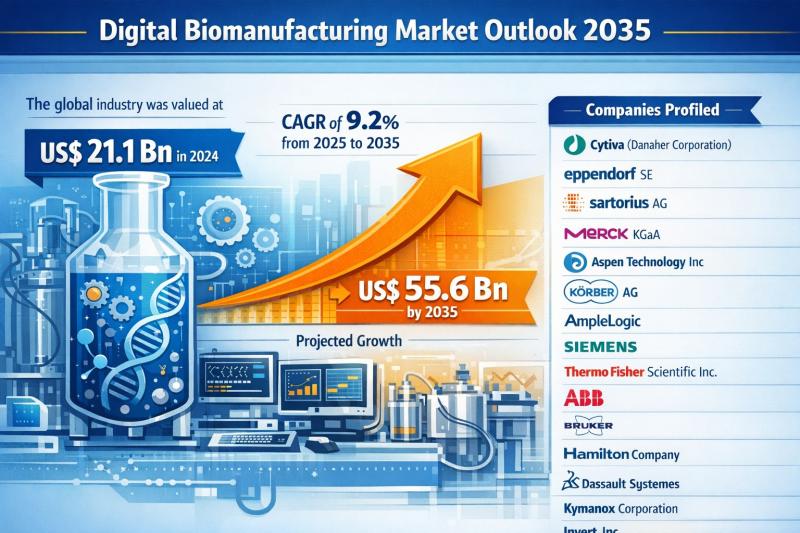

Digital Biomanufacturing Market Outlook 2035: AI-Driven MES, PAT, and Digital Tw …

The global digital biomanufacturing market was valued at US$ 21.1 Bn in 2024 and is projected to expand at a robust CAGR of 9.2% from 2025 to 2035, crossing US$ 55.6 Bn by the end of 2035. The strong double-digit expansion trajectory underscores the accelerating adoption of digital tools across biologics production facilities worldwide.

Between 2020 and 2024, the market witnessed steady adoption, supported by rapid digitalization efforts following pandemic-driven supply…

More Releases for Flexographic

Flexographic Ink Market

The global flexographic ink market is poised for significant expansion, with its valuation expected to rise from USD 4.48 billion in 2025 to USD 7.3 billion by 2035. This growth, moving at a compound annual growth rate (CAGR) of 5.0%, is underpinned by the rapid expansion of flexible packaging and the surging demand for corrugated cardboard within global e-commerce distribution channels.

Get Access of Report Sample : https://www.factmr.com/connectus/sample?flag=S&rep_id=11728

Flexographic Ink Market…

Flexographic Printing - A Complete Guide

Flexographic Printing (often called flexo printing) is a high-speed printing process used for packaging and labels. It uses flexible relief plates made of rubber or photopolymer to print on a wide variety of materials.

Download PDF:- https://www.theinsightpartners.com/sample/TIPRE00039436?utm_source=Openpr&utm_medium=10413

Flexographic Printing Market Segmentation

Offering

Flexographic Printing Machine

Flexographic Printing Ink

Application

Corrugated Packaging

Flexible Packaging

Labels & Tags

Automation Type

Automatic

Semi-automatic

Market leaders and key company profiles

Bobst

Mark Andy Inc.

Windmöller & Hölscher

Heidelberger Druckmaschinen AG

MPS Systems B.V.

NilpeterA/S

Amcor Plc

Rotatek

Koenig & Bauer AG

Comexi

Contact Us :

If you have any…

Transforming the Flexographic Printing Market in 2025: Flexographic Printing Mar …

What Is the Expected Size and Growth Rate of the Flexographic Printing Market?

The market for flexographic printing has experienced significant expansion in the past few years. Its size is projected to increase from $6.5 billion in 2024 to $7.11 billion in 2025, with a compound annual growth rate (CAGR) of 9.4%. Factors contributing to this historic growth include greater cost-effectiveness, faster printing speeds, versatility with different substrates, superior quality and…

Transforming the Flexographic Printing Market in 2025: Flexographic Printing Mar …

What Is the Expected Size and Growth Rate of the Flexographic Printing Market?

The market for flexographic printing has experienced significant expansion in the past few years. Its size is projected to increase from $6.5 billion in 2024 to $7.11 billion in 2025, with a compound annual growth rate (CAGR) of 9.4%. Factors contributing to this historic growth include greater cost-effectiveness, faster printing speeds, versatility with different substrates, superior quality and…

Flexographic Printing Technology Market Size in 2023 To 2029 | BOBST, SOMA Engin …

Flexographic Printing Technology market research delivers comprehensive insights into the current state of the market. It covers market size in terms of valuation, sales volume, and offers precise predictions for the market scenario over the estimated period. This research focuses on products, technology, manufacturers, suppliers, and regional segments within the Flexographic Printing Technology market. The report highlights market-driving factors, growth overview, industry volume, and market share.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐅𝐫𝐞𝐞 𝐏𝐃𝐅 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭…

Increasing Preference for Flexographic Printing over Other Printing Methods Driv …

Flexographic printing machines use a flexible printing plate, which is wrapped around a printing cylinder. The printing plate is inked using a roll of ink, and the image is then transferred to the substrate (paper or other material) as it passes through the printing press. Flexographic printing machines are used for a variety of print applications, including newspapers, magazines, packaging, and labels.

Request free sample copy of this research study: https://www.globalinsightservices.com/request-sample/GIS10174

Key…