Press release

How To Determine the Best Equipment for the Booming Lead-Acid Battery

Lead-Acid Batteries are used every day in areas ranging from freight trains to lawn tractors. The batteries are popular because for the most part, they don't require a ton of maintenance, they are extremely durable, reliable, and recyclable.Current Market Trends

Even though the lead-acid battery process has stayed very much the same over the course of its existence, customers still want to perfect their curing recipes and processes to minimize waste and improve efficiency-not only efficiencies within the manufacturing process but also efficiency in the batteries themselves.

Curing and drying are integral steps in the lead-acid battery manufacturing process. It's extremely important for the curing chambers to maintain specific conditions including temperature and humidity. Typically, manufacturers keep their specifics (time, temperature, humidity) of this step guarded closely.

Four Key Global Battery Manufacturing Trends:

1. Improve plate processing by implementing robotic stacking of the plates rather than manual stacking to reduce human exposure to lead.

2. Reduce curing times while maintaining advanced crystal growth.

3. Find innovations of separator materials and ingredients in the lead oxide recipes to prolong battery life and defend against stratification.

4. Improve manufacturing solutions in lead-acid battery manufacturing facilities to improve quality and battery production per square foot of factory.

How to choose the best OEM partner for your battery production?

Look for an OEM with:

- Long track record of providing lead-acid battery technology with efficient equipment

- Experience in supporting both large and small global companies

- Ability to support customers with state-of-the-art curing chambers

- Capabilities around the development of custom curing ovens and drying chambers

Most importantly… find a company familiar with the challenges in operating a battery production line efficiently and knows how to reduce bottlenecks. For example, proper utilization of the curing chambers' design and size can be a challenge. If the chamber design is undersized, the production rate will fall short. If the curing chamber is over-sized, excessive curing time cycles will occur. The right sized curing chamber can greatly reduce overall cycle times and energy consumption.

About International Thermal Systems

ITS works with global customers to determine their need, develop the right solution, install and start up the equipment. From here, it is the continuous interaction from which the customer can lean on the ITS expertise to maximize the efficiency of their cycle.

ITS is a true partner rather than just another vendor. We stand behind the craftsmanship of our ovens long after they leave our facility. Our products are different from others in the market due to their ability to reduce lead dust in the air during the manufacturing process.

ITS current equipment offerings for lead-acid battery manufacturing include:

HydroCure ™ Chambers: A combination Humidity/Drying chambers that are recognized in the battery industry as the leader in reliability, innovative and intuitive operator friendly design. ITS has installed 1000's of HydroCure™ Combination Humidity/Drying Chambers throughout the world.

FlashMaid ™ Dryer: These machines are built specifically for the customer's manufacturing line. The FlashMaid is unique in the industry as it cleans (hence "Maid) itself following the drying process, a feature competing OEM products lack. This feature allows for less free lead in the air, less down time for maintenance, enhanced temperature uniformity on the parts, less wasted energy through heat absorption, and less restricted air flow because of trapped dust inside the dryer ductwork.

The ITS battery division also specializes in Trim Dryers (Thermal Degreasers), Fume Hoods, Battery Case Washers, Custom Conveyor Ovens, Solder Pots, and any other custom equipment that your factory requires.

ITS continues to innovate and deliver solutions with ever-increasing efficiency, smaller footprints, and lower energy consumption to help you meet sustainability goals.

Contact a representative today to arrange an on-site consultation to learn how ITS provides a state-of-the-art solution for you.

https://www.internationalthermalsystems.com/lead-acid-battery-equipment-manufacturer/

International Thermal Systems LLC

3000 North 114th Street

Wauwatosa, WI 53222 USA

Main: 414-672-7700

Press:

Nanette Gregory

nanette@nsgconsultinginc.com.

ITS - International Thermal Systems is a global original equipment manufacturer of industrial ovens, furnaces, and aqueous washers for automotive, aerospace, power generation, battery manufacturing, building products, foundry, and metal packaging industries. ITS is in Wauwatosa, Wisconsin, USA, with another manufacturing facility in Shanghai, China. Learn more by visiting us online:

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How To Determine the Best Equipment for the Booming Lead-Acid Battery here

News-ID: 2614122 • Views: …

More Releases from International Thermal Systems

International Thermal Systems Works with Customer, to Design a New Aluminum Beve …

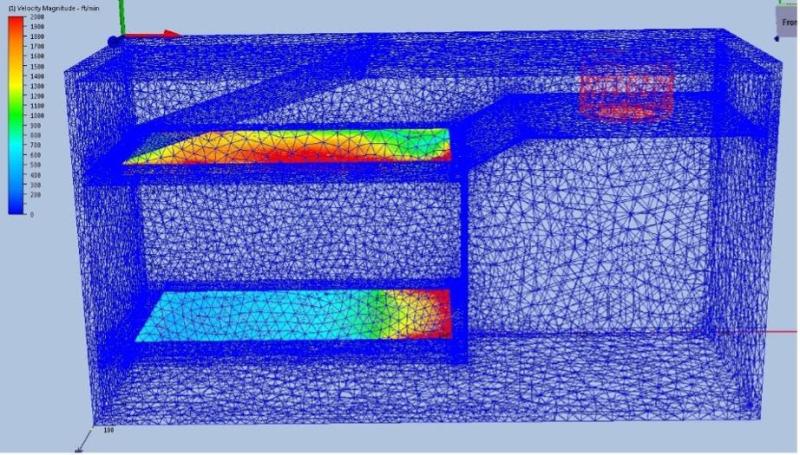

The ITS R&D and Engineering departments are one-of-a-kind in both the heat processing and aqueous washing industries. Together, these departments work to help our customers solve specific processing issues before the customer commits to an equipment purchase.

At ITS, we typically start the validation of customer-specific heating/washing processes for a new machine by having our R&D lab use our versatile lab oven and washer, in-house heat transfer program, and Computational Fluid…

International Thermal Systems (ITS) Offers Upgrades Existing / Obsolete MicroLog …

Many manufacturing facilities rely on MicroLogix controllers to automate their processes efficiently. However, as technology evolves, older MicroLogix controllers can become obsolete, leading to performance issues and increased downtime.

Manufacturers face several challenges with older controllers such as:

1. Limited Capabilities: Older MicroLogix controllers may lack the processing power and memory required for modern automation needs, limiting their functionality, and slowing down your processes.

2. Compatibility Issues: As newer software and hardware components…

International Thermal Systems Revolutionizes Industrial Manufacturing with Innov …

Cutting-edge solutions offer enhanced efficiency and sustainability for manufacturing processes. International Thermal Systems, a global leader in thermal processing solutions, proudly announces the use of groundbreaking RollSeal® Door technology in their ovens. This innovative solution is set to transform industrial manufacturing processes by significantly improving efficiency, sustainability, and overall performance.

The ITS RollSeal® Door retrofit brings a compact, energy efficient, and safe design to batch and conveyor style thermal processing…

Five Principles for Designing Industrial Manufacturing Equipment to Meet Your Su …

Energy-intensive industries such as manufacturers in the automotive, aerospace, power generation, battery manufacturing, building products, foundry, ice builders, and metal packaging often have higher energy consumption costs compared to other industries.

In 2021, the industrial sector accounted for 35% of total U.S. end-use energy consumption and 33% of total U.S. energy consumption. https://www.eia.gov/energyexplained/use-of-energy/industry.php

Here are five principles to follow when looking for new equipment that will lessen your company's impact on…

More Releases for OEM

OEM Partnership Guide: Working with a Touch-free Automatic Kitchen Garbage Can O …

With increasing global demand for smart home solutions, Sinoware International Ltd, a top provider in household products industry, is pleased to unveil expanded OEM partnership initiatives.

Sinoware has established itself in Jiangmen--China's premier stainless steel industry zone--as an indispensable touch-free automatic kitchen garbage can OEM manufacturer for global brands seeking to incorporate high-tech sanitation solutions into their portfolios.

By combining their decades-old tradition of metal craftsmanship with cutting-edge infrared and…

Revolutionizing OEM Coatings With Sustainable Solutions Trend: A Crucial Influen …

Which drivers are expected to have the greatest impact on the over the oem coatings market's growth?

The surge in requirements from final consumer industries is forecasted to boost the expansion of the OEM coatings market. These coatings, referred to as OEM, are utilized during the integration of other firms' products into the substrate process or application. They prove to be beneficial for a variety of end-user sectors, including automotive and…

OEM Technology Partnerships Launches Brokerage Specializing in 100+ OEM Technolo …

San Francisco, California, USA - February 13, 2025 - OEM Technology Partnerships is thrilled to announce the launch of its specialized brokerage focused on connecting businesses with a comprehensive portfolio of over 100 Original Equipment Manufacturer (OEM) technologies. This new venture is poised to revolutionize how companies access and implement cutting-edge solutions across diverse industries.

Leveraging deep industry expertise and a vast network of OEM partners, OEM Technology Partnerships offers a…

OEM or ODM Watches? What's the Difference?

When searching for a watch manufacturer for your store or watch brand, you may come across the terms OEM and ODM. But do you truly understand the difference between them? In this article, we will delve into the distinctions between OEM and ODM watches to help you better grasp and choose the manufacturing service that suits your needs.

Image: https://www.naviforce.com/uploads/15a6ba3911.png

What's OEM / ODM Watches [https://www.naviforce.com/products/]

OEM (Original Equipment Manufacturer) watches are produced…

OEM Partnership with Extreme Networks

ComputerVault announces an OEM partnership with Extreme Networks and has certified its switches for use with ComputerVault enterprise software to deliver virtual desktop infrastructure (VDI).

Extreme Networks industry leading switches deliver ComputerVault Virtual Desktops at faster than PC speeds in the LAN and WAN.

“ComputerVault is very excited to work with Extreme Networks. Not only are their switches very reliable, but their exceptional performance guarantees a great user experience”, said Marc…

Humidity Measurement Module for OEM Applications

The EE1900 humidity module from E+E Elektronik is optimised for the measurement of relative humidity (RH) or dew point temperature (Td) in climate and test chambers. With outstanding temperature compensation across the working range from -70 °C to 180 °C (-94 °F to 356 °F) and the choice of stainless steel and plastic probes, the module is suitable for a wide range of applications.

High Accuracy in Harsh Environment

The excellent…