Press release

DSI Announces Specialized LPCVD Thin Film Coating Process for Complex Shapes/Surfaces

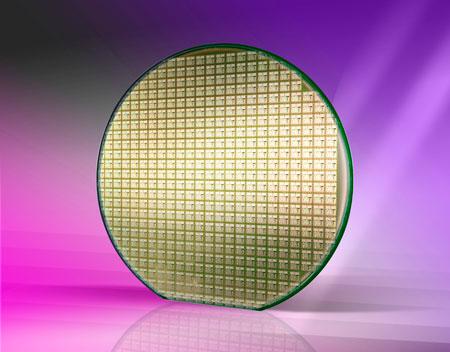

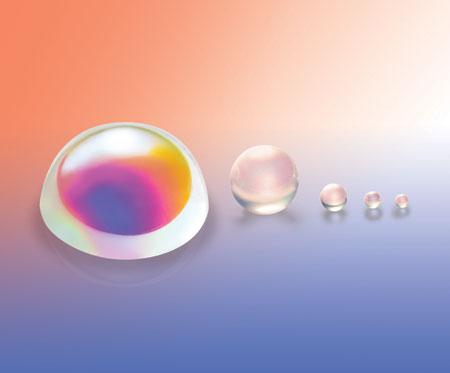

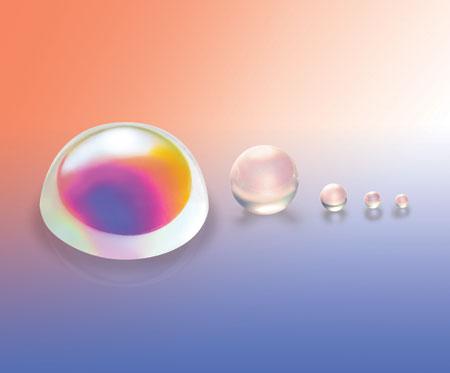

Deposition Sciences, Inc. (DSI®), global manufacturer of highly durable thin film optical coatings, announces the enhanced capability to apply highly specialized, durable coatings onto extremely complex shapes and multifaceted surfaces. Utilizing DSI’s proprietary IsoDyn™ LPCVD (low pressure chemical vapor deposition), this method is ideal for coating almost all types of optical glass crystalline materials, ceramics, and metals. It is also ideal for coating a wide variety of unusual geometries: from ball lenses to dome windows; from optical fibers to cold mirror reflectors.Director of marketing and sales, Michael Newell, notes, “We are very excited to announce this enhanced capability in uniform, optical thin film coatings. DSI’s IsoDyn LPCVD process, a high temperature process (approx. 500 degrees C), is used in the manufacture of micro-optics, interference filter coatings (such as single wavelength, dual band, and broadband AR), cold mirrors, conductive coatings and dichroics. Our enhanced method is permitting exceptionally conformal coatings on many complex substrate geometries.”

For more information, please visit: www.depsci.com.

Deposition Sciences, Inc. (DSI) – Santa Rosa, CA – www.depsci.com - For over 25 years, Deposition Sciences has produced the most durable optical thin film filter coatings in the industry. DSI’s coating capability ranges from the ultraviolet (UV), through the visible and includes near-infrared (NIR), midwave-infrared (MWIR) and out to the longwave-infrared (LWIR). At the heart of these coating capabilities for optics and other thin film technologies are DSI’s patented MicroDyn® reactive sputtering technology enabling superior multilayer thin film coatings, and the company's IsoDyn™ LPCVD method that permits exceptionally conformal optical coatings on complex shapes and sizes.

Deposition Sciences, Inc. (DSI)

3300 Coffey Lane

Santa Rosa, CA 95403

Contact: Tatiana Atkinson

Inside Sales Manager

Phone: 707-573-6785

Fax: 707-573-6748

Email: Solutions@depsci.com

Web Site: www.depsci.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release DSI Announces Specialized LPCVD Thin Film Coating Process for Complex Shapes/Surfaces here

News-ID: 252099 • Views: …

More Releases from Deposition Sciences, Inc. (DSI)

DSI® Introduces Solderable Coatings and Face Metallization Optical Coatings

Santa Rosa, CA – Deposition Sciences, Inc. (DSI®), global manufacturer of highly durable thin film optical coatings, introduces thin film solderable coatings and face metallization, available on a wide variety of substrates. Although silicon is the most frequently used substrate, the coatings can be applied to virtually all commonly used optical materials. The new thin film coating capabilities are enabled by DSI’s proprietary MicroDyn® sputtering deposition technology. The face metallization…

DSI® Introduces High Laser Damage Threshold (LDT) Coatings

Santa Rosa, CA – Deposition Sciences, Inc. (DSI®), global manufacturer of highly durable thin film optical coatings, introduces a new line of high laser damage threshold (LDT) coatings. Designed for use with lasers and other high energy systems, these coatings are ideal for diode, diode-pumped solid-state (DPSS), and gas lasers. DSI’s new products feature laser damage threshold levels as high as 25 MW/cm2. …

DSI® Introduces High Laser Damage Threshold (LDT) Coatings

Rosa, CA – Deposition Sciences, Inc. (DSI®), global manufacturer of highly durable thin film optical coatings, introduces a new line of high laser damage threshold (LDT) coatings. Designed for use with lasers and other high energy systems, these coatings are ideal for diode, diode-pumped solid-state (DPSS), and gas lasers. DSI’s new products feature laser damage threshold levels as high as 25 MW/cm2.

High…

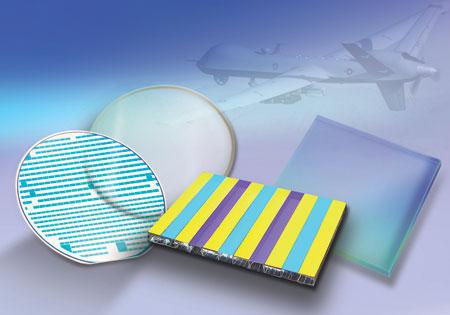

DSI® Announces Highly Durable, Optical Thin Film Coatings for Unmanned Aircraft …

• Deposition Sciences will present ruggedized optical coatings for unmanned systems in booth # 3053 at AUVSI (Washington, D. C.), August 13 - 15, 2013. To view DSI’s online press kit, please go to: virtualpressoffice.com/kit/kg7m.

Santa Rosa, CA – Deposition Sciences, Inc. (DSI®), global manufacturer of highly durable thin film optical coatings, announces plans to showcase specialized optical thin films for unmanned aircraft systems at AUVSI, Walter E. Washington Convention Center,…

More Releases for DSI

New flexBridge HDMI to MIPI-DSI Interface-Bridging for LCD Panels

Display Solution launches the first member of its innovative Bridge Module Concept for LCD Video Interfaces like TTL, HDMI, e/DP, LVDS and MIPI-DSI

Display Solution AG, a leading industrial TFT display and Digital Signage LCD solutions specialist, launches the HDMI-to-MIPI-DSI module, the first member of their new in-house developed and manufactured flexBridge product family.

flexBridge is an innovative Video Interface-Bridging Module (BM) Concept for various combinations of different video sources and…

DSI® Introduces Solderable Coatings and Face Metallization Optical Coatings

Santa Rosa, CA – Deposition Sciences, Inc. (DSI®), global manufacturer of highly durable thin film optical coatings, introduces thin film solderable coatings and face metallization, available on a wide variety of substrates. Although silicon is the most frequently used substrate, the coatings can be applied to virtually all commonly used optical materials. The new thin film coating capabilities are enabled by DSI’s proprietary MicroDyn® sputtering deposition technology. The face metallization…

DSI® Introduces High Laser Damage Threshold (LDT) Coatings

Santa Rosa, CA – Deposition Sciences, Inc. (DSI®), global manufacturer of highly durable thin film optical coatings, introduces a new line of high laser damage threshold (LDT) coatings. Designed for use with lasers and other high energy systems, these coatings are ideal for diode, diode-pumped solid-state (DPSS), and gas lasers. DSI’s new products feature laser damage threshold levels as high as 25 MW/cm2. …

DSI® Introduces High Laser Damage Threshold (LDT) Coatings

Rosa, CA – Deposition Sciences, Inc. (DSI®), global manufacturer of highly durable thin film optical coatings, introduces a new line of high laser damage threshold (LDT) coatings. Designed for use with lasers and other high energy systems, these coatings are ideal for diode, diode-pumped solid-state (DPSS), and gas lasers. DSI’s new products feature laser damage threshold levels as high as 25 MW/cm2.

High…

DSI CONQUERS THE BIG APPLE WITH NEW MANHATTAN NY OFFICE

New York, NY (March 1, 2011) – More directly servicing the needs of East Coast clients, Dependable Solutions, Inc. has opened offices in New York City at 1325 Ave of the Americas, 27th Floor. While helping the company keep up with the growing demand for stronger brand licensing solutions, DSI’s New York office will be able to better help licensors, agents and licensees learn how to improve their brand…

DSI Offers Infrared Narrow Bandpass Optical Filters for Spectroscopy

Deposition Sciences, Inc. (DSI), manufacturer of highly durable thin film optical coatings, introduces advanced Infrared Narrow Bandpass (IR NBP) Filters for industrial, medical, and biological sciences instrumentation. The improved narrow bandpass optical filters offer high spectral performance, with accurate center wavelength placement, and good temperature stability which makes the infrared NBPs ideal for spectroscopic applications such as advanced gas-sensing. The NBP filters’ IR spectral range enables the user…