Press release

Will automate and revolutionize slaughterhouses

RoBUTCHER, a European funded H2020 innovation project, will change the way slaughterhouses operate and therefore improve the working environment.The last months there have been several big outbreaks of COVID-19 in slaughterhouses and meatpacking plants in Europe. There are several responsible factors, including the typically cold and damp working areas being perfect environments for coronavirus to linger and spread, as well as difficulties keeping distance when personnel are working closely on fast-moving production lines.

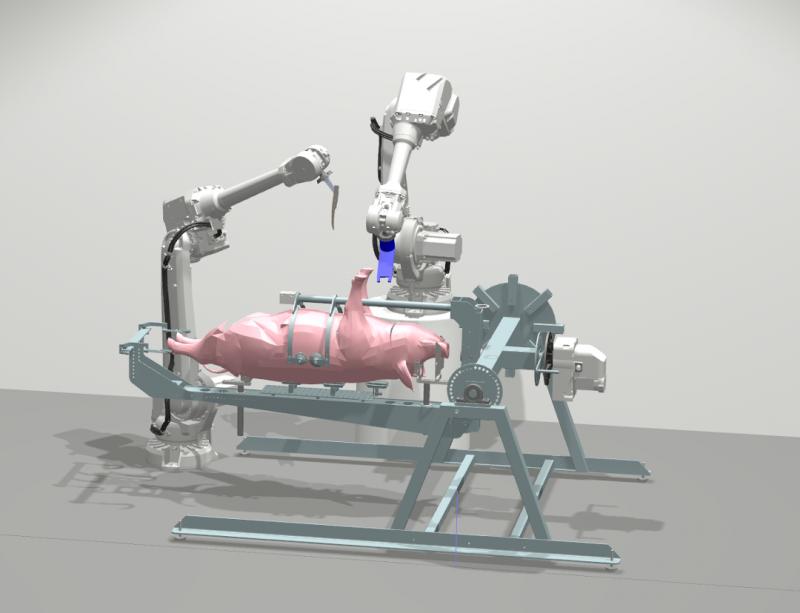

Today’s abattoirs use a «disassembly line» approach. Carcasses are processed as they move along a rail or conveyor, with personnel or machines performing limited serial operations within a short time window. The RoBUTCHER project that started in January this year aims to replace the conventional line production, with parallel production in autonomous “meat factory cells”. A meat factory cell contains robots that lift, hold, cut and debone the carcass, enabling distribution of primal cuts from these autonomous cells. In daily operation the human- operator will only monitor the process and there will be no need for human interaction with the robots. Human intervention must still be an option to handle abnormal situations.

The use of meat factory cells working in parallel offers robustness against equipment failure, scalability to different production volumes and flexibility to adjust to demand – when you need more capacity, you can have more cells running.

In the RoBUTCHER concept the robotic system will be able to understand and plan cutting trajectories based on the carcass that is presented. To achieve this, it will use a combination of detailed computed tomography (CT) data, real-time 3D imagery and human-expert cutting data for neural network training toward cutting trajectory planning. The fixation with line production in the meat sector has meant that automation solutions, particularly for slaughter, cutting or deboning processes, require big investments and are only accessible to the very largest of meat producers. The RoBUTCHER concept aims for smaller producers to be able to automate their production more cost effectively than is possible today.

– RoBUTCHER will use advances in artificial intelligence and robotics research to increase the accessibility of automation to meat producers, regardless of production volume, enabling much wider standardisation and optimisation of meat processing than today. It also aims to significantly improve the quality of the working environment within the sector, reducing the exposure of workers to dangerous and repetitive tasks, as well as increasing security and equality. The COVID-19 outbreak only makes the concept more relevant, as it will reduce the need for tightly packed working conditions which encourage the virus to spread, , says Alex Mason, project manager for RoBUTCHER.

Contact:

Project Co-ordinator : Alex Mason, phone +47 917 49 792 alex.mason@nmbu.no

Postal Adress:

Robutcher

Postboks 396 - Økern, 0513 OSLO

NORWAY

Facts about RoBUTCHER

The project has received 7,5 million euros by EUs Research and Innovation programme – Horizon 2020. It led by The Norwegian University of Life Sciences (NMBU) and contains of ten partners within robotics, digital solutions, academia and meat industry.

Partners:

- Norwegian University of Life Sciences

- Animalia (Norway)

- Óbuda University (Hungary)

- Danish Technological Institute (Denmark)

- Max Rubner-Institut (Germany)

- NORSUS (Norway)

- Byte Motion (Sweden)

- Ciklum (global)

- RobotNorge (Norway)

- FACCSA (Spain)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Will automate and revolutionize slaughterhouses here

News-ID: 2134459 • Views: …