Press release

The world's most expensive label and how to avoid it

When the world wastes a third of all its food, businesses can't afford to be complacent about coding and labelling their packaged food productsPerhaps among the most important pieces of information, we read daily are the labels on our food. In a small space, they pack in the detail, telling us what's inside, how to cook it, how to serve it, what it's made of, and when it stops being good to eat.

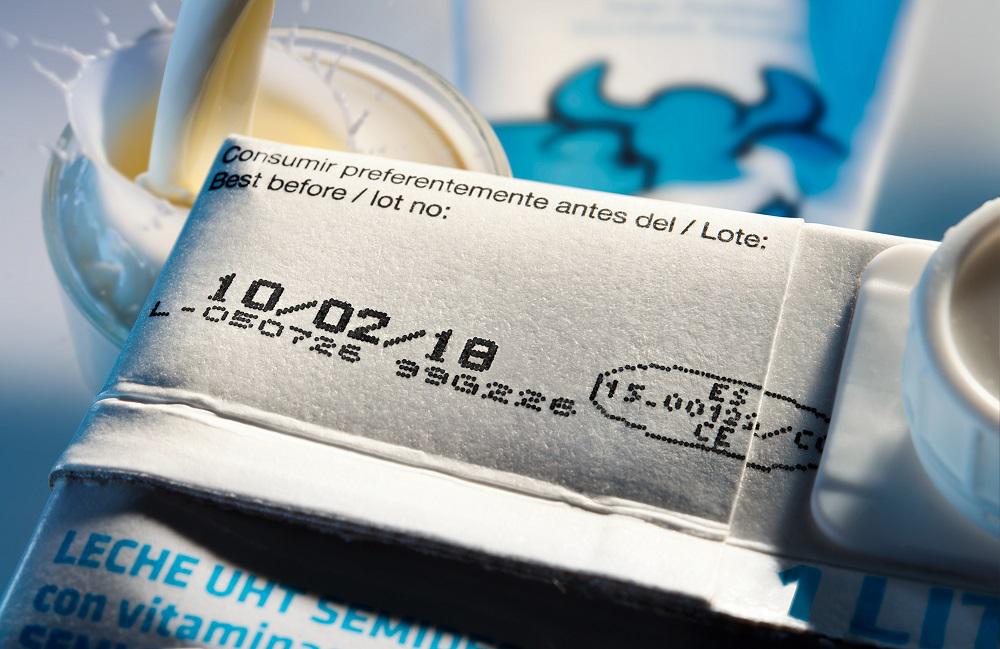

Take a closer look and you'll see that labels also carry other information which we might not pay attention to, but which ensure the food we eat is safe and kept at a high standard. These are called production codes, which allow a manufacturer to see what batch a product is from, which production line it was made on, even where an individual item was filled and sealed.

Printing a date or a product code on food packaging doesn't sound like the realm of high tech, but any smudging and smearing of bad printing can make food untraceable, and mislabelling due to human error can make perfectly good, but wrongly labelled food, unsellable.

Not only is it important that the food we eat is traceable from a standards perspective, it's also a moral issue: the Food and Agriculture Organization of the UN claims that "roughly one-third of the edible parts of food produced for human consumption gets lost or wasted globally" - around 1.3 billion tons per year.

If accurate labelling can prevent waste, saving businesses money and giving them confidence that their food can be shown to be of a high standard, then printing technology is very important indeed.

Take Emmi for example, which processes around a million tons of milk at 25 different production facilities around Switzerland. The company is number one in the Swiss market for milk. At their plant in Ostermundigen they process 330 tons of milk every day - around a tenth of all the milk they work with - producing 1,500 different products which are all filled and packaged on 20 production lines.

Understandably, keeping track of what was processed and where is a complex and vital task. The bestsellers from this particular Emmi plant are cups of caff? latte which come in ten variations - correct labelling and clear printing is critical to ensuring the right cup is marked up as containing the right coffee.

"No cup leaves the plant without information about the production line on which it was filled," explains plant manager Isidor Lauber: "The date it was filled, and the best before date, as well as which lane the individual cups were filled and sealed on."

This is no small undertaking - 36,000 cups are filled every hour on the plants ten-lane machines, and the printing needs to keep pace while delivering clarity. Hitachi's continuous inkjet printers are among the most advanced in the world, and Emmi has found them to be entirely reliable in the labelling and coding of their milk products, even working well at a production temperature of 50?C on the yogurt line.

Similarly, major German dairy found Hitachi's end-to-end printing system to be invaluable at their factory in Spain factory in Viladecans near Barcelona. With work orders changing up to 15 times a day, a lot of manual effort was required to make sure the right data went on the right product. The number of changes left room for human error, with all the associated costs of waste that comes from incorrect coding and mislabelling.

Hitachi implemented a system which integrated the printers with the dairy's Manufacturing Execution System (MES), meaning that, as bulk orders were being handled and instructions sent to the production lines, the printers were part of this, saving production line operators from having to input the data into the printers manually.

"The new automated process means we can have much greater confidence in the way our units are labelled," says their Head of Operations. "We can now initialise our printers at the same time we initialise MES. The process is simpler which means it's harder for our products to be wrongly coded or marked."

When unclear or mislabelled food products can result in product recalls, lawsuits and high-profile brand damage, it's clear that the world's most expensive label is a wrong label. But by streamlining, simplifying, and integrating printing into the manufacturing process as a whole, as well as ensuring the technology is spot on to deliver clarity and accuracy, regardless of the ambient temperature or what the surface is to be printed on, food manufacturers and processors can save money - and be part of the solution to global food waste as they do it.

https://youtu.be/8xIIsg2DBvI

Hitachi Europe GmbH

Marketing

Niederkasseler Lohweg 191

40547 Duesseldorf

Germany

Hitachi Europe Ltd. is the parent company to Hitachi Europe GmbH, "Industrial Components & Equipment group" and a wholly owned subsidiary of Hitachi, Ltd., Japan. Headquartered in Maidenhead, UK, it has operations in 13 countries across Europe, the Middle East and Africa and employs approximately 550 people. Hitachi Europe comprises of nine business areas: rail systems; power and industrial systems; information systems; digital media and consumer products; display products; industrial components and equipment; air conditioning and refrigeration systems; manufacturing systems; and procurement and sourcing. Hitachi Europe also has three Research and Development laboratories and a design center in Europe. www.hitachi-industrial.eu

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The world's most expensive label and how to avoid it here

News-ID: 1992987 • Views: …

More Releases from Hitachi Europe GmbH

Driving Energy Efficiency and Sustainability: Hitachi's H-Vision Method Delivers …

June, 2025 As global industries face increasing pressure to improve energy efficiency, reduce emissions, and contribute to global climate goals, Hitachi (HIES-EU) offers a proven solution that is gaining renewed relevance: H-Vision.

Developed by the company's Energy Efficiency & Sustainability Business Unit, H-Vision is more than just a monitoring tool-it's a comprehensive energy intelligence method that enables companies to understand, control, and continuously improve their energy consumption across facilities and…

Fachpack : Human centered maintenance and repair technology using AI, AR and Hum …

Düsseldorf, 17th July 2019

Nowadays, maintenance & repair (M&R) industry is facing challenges such as a shortage of skilled workers and increased complexity of machine maintenance operations. On one hand, it has become increasingly important to assist maintenance workers not only in the training phase but also in the operation phase to handle various and sometimes complex maintenance task in a specific manufacturing environment in order to ensure work quality and…

An Insignificant Detail - Printing on Window Spacer

The Spacer is the outside seal on a glass edge. It is relative to the frame and the glazing only adjusted in a small area ratio. In fact, the growing influence of the Spacer should not be underestimated.

In accordance with European standards (EN 14351-1/SIA 331), the manufacturer is required to print important information on the Spacer, including:

■ Manufacturer’s name

■ Production number

■ ug - value / g value (technical data covering…

Coding Solution for the Dairy Industry

The traceability requirements for the dairy industry creates a need for more and more tagged information. Today's dairy processors and packers use a wide variety of technologies and materials. To handle this diversity of materials, needs and requirements of customers and industry pose a challenge for industrial printers.

The key requirements of coding and marking equipment in the dairy industry are accuracy and machine durability. It is important that you achieve…

More Releases for Emmi

Dairy Food Market Is Booming So Rapidly | Amul, Chobani, Emmi Group

The Global Frozen and Freeze-dried Pet Food Market size is estimated at $5.1 Billion in 2025 and is forecast to register an annual growth rate (CAGR) of 11.2% to reach $13.3 Billion by 2034. Download now

The latest study released on the Global Dairy Food Market by USD Analytics Market evaluates market size, trend, and forecast to 2034. The Dairy Food market study covers significant research data and proofs to be…

Organic Milk Products Market Growth Holds Strong | Nestle, Danone Group, Emmi

A new business intelligence report released by USD Analytics with title "Global Organic Milk Products Market Report 2030 " has abilities to raise as the most significant market worldwide as it has remained playing a remarkable role in establishing progressive impacts on the universal economy. The Global Organic Milk Products Market Report offers energetic visions to conclude and study market size, market hopes, and competitive surroundings. The research is derived…

Goat Milk Market Next Big Thing | Emmi AG, Lactalis, Hay Dairies, Meyenberg

The latest study released on the Global Goat Milk Market by AMA Research evaluates market size, trend, and forecast to 2027. The Goat Milk market study covers significant research data and proofs to be a handy resource document for managers, analysts, industry experts and other key people to have ready-to-access and self-analyzed study to help understand market trends, growth drivers, opportunities and upcoming challenges and about the competitors.

Download…

Organic Milk Market is Booming Worldwide | Organic Valley, Emmi, Yeo Valley

The latest research on "Organic Milk Report 2021" offered by HTF MI provides a comprehensive investigation into the geographical landscape, industry size along with the revenue estimation of the business. Additionally, the report also highlights the challenges impeding market growth and expansion strategies employed by leading companies in the "Market".

Get Free Sample PDF including full TOC, Tables and Figures and Available customizations) in Organic Milk: https://www.htfmarketreport.com/sample-report/3088510-organic-milk-market-3

Proceeding further, the business intelligence…

Skim Yogurt Market Boosting the Growth Worldwide | Nestle, Danone, Chobani, Emmi …

Advance Market Analytics published a new research publication on "Skim Yogurt Market Insights, to 2027″ with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Skim Yogurt market was mainly driven by the increasing R&D spending across the world.

Some of the key players profiled in…

Global Ultrasonic Toothbrush Market 2017 - Philips Sonicare, Ultrasonex, EMAG Em …

Ultrasonic Toothbrush Market Research Report

A market study based on the " Ultrasonic Toothbrush Market " across the globe, recently added to the repository of Market Research, is titled ‘Global Ultrasonic Toothbrush Market 2017’. The research report analyses the historical as well as present performance of the worldwide Ultrasonic Toothbrush industry, and makes predictions on the future status of Ultrasonic Toothbrush market on the basis of this analysis.

Request For Sample…