Press release

VITROBRAZE in IGBT copper coolers: From traditional diesel to modern electric car

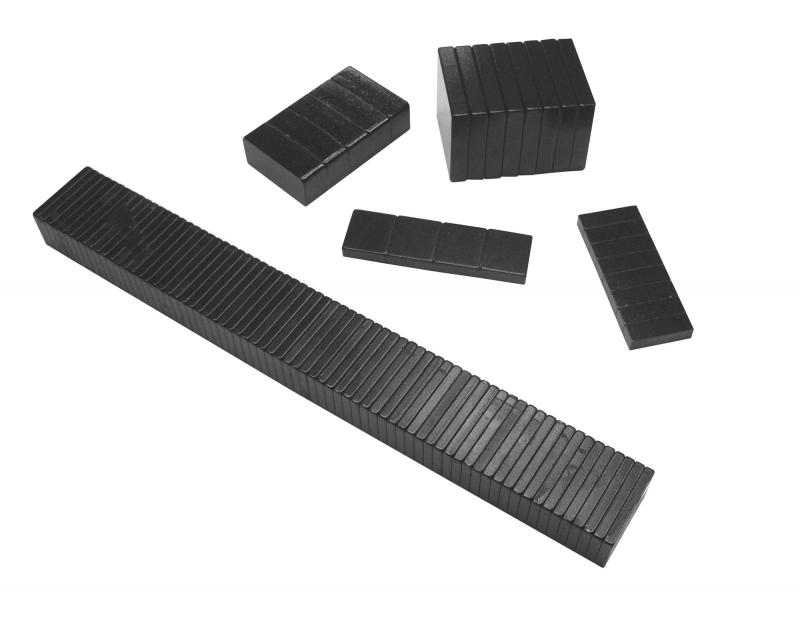

Copper coolers in automobiles are currently experiencing a renaissance after aluminium coolers dominated the market for a long time for price reasons. The reason for this is the use of IGBT modules in electric or hybrid-electric vehicles, which require very efficient heat dissipation for reliable operation. Amorphous copper-based brazing foils made of VITROBRAZE make the production of such highly efficient copper coolers possible.VITROBRAZE stands for 100% metallic brazing materials based on nickel, nickel-iron or copper - free of organic binders. The brazing foils are characterized by simple, uncomplicated processing as well as outstanding flow properties and uniform brazed joints of outstanding quality. They are ideally suited for flat, rectangular geometries with narrow cooling channels, without having to use flux or extract combustion gases from the organic binders. Thus, particularly compact and efficient coolers can be brazed in a health-friendly way.

The copper-based VITROBRAZE alloys VZ2250 and VZ2255 are primarily used for joining copper and brass heat exchangers in industrial and automotive applications. They are available as strip and can be adapted to the required geometry by cutting to length or punching. For use in automated production and assembly steps, preforms can be easily produced, reducing scrap and increasing production efficiency. In some cases it is also possible to replace expensive silver-containing brazing alloys with copper-based VITROBRAZE brazing foils. All this allows the construction of thermally high performant copper coolers at low manufacturing costs.

"The traditional market for copper coolers has been expanded to include IGBT coolers with the emerging of electric or hybrid electric vehicles. We are in contact with all major automotive suppliers worldwide and are already represented in the first models in IGBT coolers with our copper-based VITROBRAZE alloys", says Dr. Julia Hahn, Product Manager for amorphous materials

VACUUMSCHMELZE GmbH & Co. KG

FAO Norman Lemm

Director Business Intelligence & Communication

Gruener Weg 37

D-63450 Hanau

Phone: +49 6181 38-0

email: info@vacuumschmelze.com

VACUUMSCHMELZE (VAC) is among the world's most highly innovative developers of magnetic materials, inductive components and other related products. With a global network of Sales and Field Application Engineers, VAC designs and manufactures tailor-made solutions for a wide variety of industries, comprising renewable energies, automotive, industrial automation installation technology, and aviation.

For more information, visit www.vacuumschmelze.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release VITROBRAZE in IGBT copper coolers: From traditional diesel to modern electric car here

News-ID: 1981578 • Views: …

More Releases from VACUUMSCHMELZE

Improved magnetic properties at reasonable prices: New rare-earth permanent magn …

Hanau - Innovative ideas in product development - this is what characterizes the material specialists at VACUUMSCHMELZE (VAC), who continuously optimize the range of rare earth permanent magnets. The latest result of this development work is a new performance class of neodymium-iron-boron magnets, VACODYM 80X TP. The main features of this alloy are improved magnetic properties and higher environmental compatibility.

A reduction of volatile heavy rare earths, in this case…