Press release

GPI Prototype announces addition of EOSINT M 280 Direct Metal Laser Sintering (DMLS) Machine

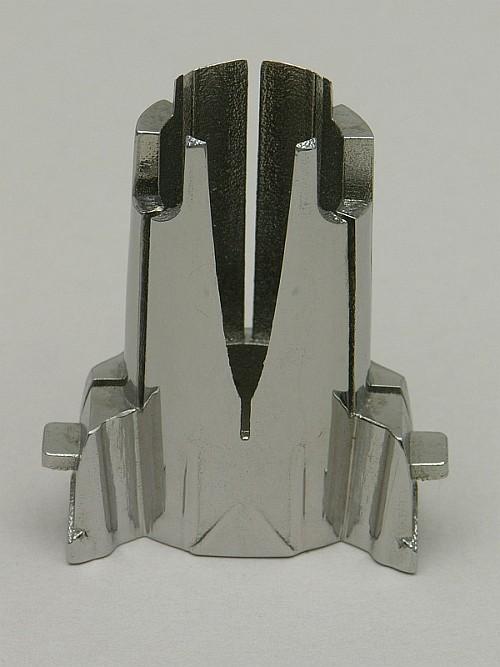

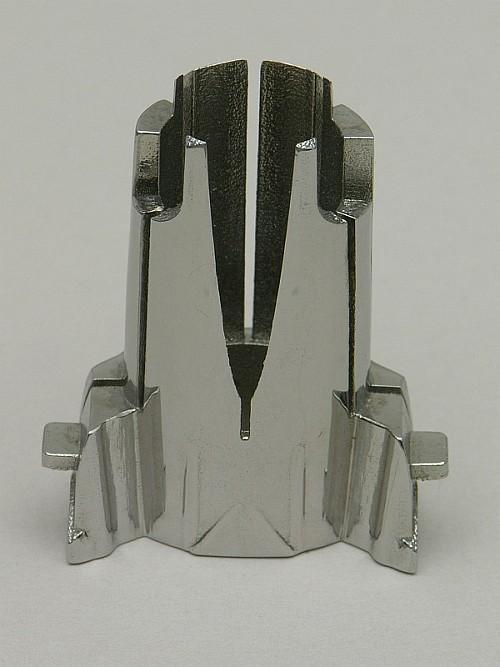

GPI Prototype announced that it has completed the installation of an EOSINT M 280 machine from EOS. The EOSINT M 280 is an updated version of the EOSINT M 270 currently being used at GPI to build metal parts additively. The addition of a second machine establishes GPI as a leader in rapid prototyping and expands their DMLS material selection to include aluminum and titanium.GPI is committed to showcasing their additive technology at industry events and informing customers of the benefits and cost savings of additive manufacturing vs traditional machining. On September 14th-15th, 2011 at the ODT Conference & Exhibition in Fort Wayne, Indiana, GPI will be showcasing parts made via DMLS at booth #803. GPI will also be exhibiting at Design & Manufacturing Midwest on September 20-22, 2011 in Chicago, IL at booth 2234. GPI has established a foothold in a variety of markets including medical, aerospace, automotive & consumer products.

DMLS offers many advantages vs traditional tooling including the ability to manufacture complex geometries and shapes not possible with CNC machining. Conformal cooling channels can also be integrated into designs to dramatically reduce injection molding cycle/lead times and lower costs. GPI offers 8 material choices for DMLS including Stainless Steel, Cobalt Chrome, Maraging Steel, Bronze Alloy, Titanium Alloy, Aluminum & Nickel Alloy. Parts can be built in 20 micron layers with a turnaround time of a few days.

Top-quality, accurate, clean prototypes can be built in hours and shipped to the customer in a few days.

Additional services include Stereolithography (SLA), Selective Laser Sintering (SLS), 3D Printing (3DP), Fused Deposition Modeling (FDM), Room Temperature Vulcanization (RTV), Investment Casting, Tooling, CNC Machining, Finishing & Painting, Laser Scanning & Packaging solutions. These services are priced very competitively in the industry while providing the best in quality and customer service.

More information is available on GPI’s full range of services at their website http://www.gpiprototype.com or by contacting a sales representative at 847-615-8900. GPI Prototype was founded in 2007 and employs 27 people from their headquarters in Lake Bluff, IL.

GPI employees are available to answer questions regarding Direct Metal Laser Sintering and the creation of metal parts through Additive Manufacturing.

940 North Shore Dr

Lake Bluff, IL 60044

Tim Ruffner

847-615-8900

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release GPI Prototype announces addition of EOSINT M 280 Direct Metal Laser Sintering (DMLS) Machine here

News-ID: 190894 • Views: …

More Releases from GPI Prototype

GPI Prototype Announces Addition of Third Direct Metal Laser Sintering Machine

GPI Prototype announced that it has completed the installation of a third DMLS machine from EOS. The additional EOSINT M 270 joins the EOSINT M270 & M280 machines currently being used at GPI to build metal parts additively. The addition of a third machine establishes GPI as a leader in metal rapid prototyping and expands their DMLS material selection to include aluminum.

DMLS offers many advantages vs traditional tooling…

GPI Prototype Presents Additive Manufacturing technologies at Design & Manufactu …

GPI Prototype announced that it is showcasing and presenting its additive manufacturing capabilities at the Design & Manufacturing Texas show in Fort Worth, Texas March 14-15, 2012. GPI Prototype will be available to answer questions regarding additive manufacturing and rapid prototyping at booth 1127. GPI will also be exhibiting at NPE 2012 in Orlando, Florida from April 2-5, 2012 at booth 65039. GPI is committed to showcasing…

GPI Prototype to present Additive Manufacturing technologies at RAPID 2011 Confe …

GPI Prototype announced that it will showcase and present its additive manufacturing capabilities at the RAPID 2011 Conference & Exposition in Minneapolis, Minnesota on May 23rd-26th, 2011. GPI Prototype will be located at booth 514 and be available to answer questions regarding additive manufacturing and rapid prototyping. GPI is committed to showcasing additive technology at industry events and informing customers of the benefits and cost savings of additive…

GPI Prototype to present Additive Manufacturing technologies at the EASTEC 2011 …

Lake Bluff, Illinois – GPI Prototype announced that it will showcase and present its additive manufacturing capabilities at the EASTEC 2011 Exposition in West Springfield, Massachusetts on May 17th-19th 2011. GPI Prototype will be located at booth 5612 and be available to answer questions regarding additive manufacturing and rapid prototyping. GPI will also be exhibiting at the RAPID 2011 Conference & Exposition in Minneapolis, Minnesota from May 24th-26th…

More Releases for EOS

EOS (EOS) Price Prediction: Bitcoin Hyper (HYPER) Takes the Lead in Trend Moment …

The crypto market is shifting as Bitcoin Hyper establishes clear leadership in momentum. This introduction frames an EOS price prediction in the context of HYPER (https://bitcoinhyper.com/) momentum and broader crypto trend momentum.

Institutional flows are responding to strong Q3 S&P 500 earnings, with FactSet reporting 13.4% EPS growth as of Nov. 21 and blended revenue growth near 8.4%. Big technology names such as NVIDIA, Apple, and Microsoft, alongside ETFs like VGT…

EOS SECURE: Precision and Innovation in Lock Cylinder Manufacturing

Zhongshan, China - EOS SECURE, a leading manufacturer of high-precision lock cylinders, continues to set industry benchmarks with its advanced mechanical and electronic locking systems. Since its establishment in 2011, the company has built a global reputation for excellence, exporting to over 50 countries including Europe, North America, and Southeast Asia.

Precision Engineering at Its Core

EOS SECURE operates a 7,000 sqm ISO 9001/ISO 14001-certified factory equipped with state-of-the-art CNC machinery. This…

Kim Baker To Speak At National EOS® Conference

ST. LOUIS, MO - March 31, 2023 - Kim Baker, a highly respected corporate team builder/designer, speaker, and owner of Vivid Performance Group, announces she will speak at the 2023 U.S. EOS® Conference, April 19-21, 2023 in Indianapolis, IN.

The conference is designed for companies running on the Entrepreneurial Operating System, EOS®. It provides unique opportunities for leadership teams and decision makers from small to medium-sized entrepreneurial EOS-run companies to…

Tabetha Sheaver Joins EOS as a Professional Implementer

Tabetha Sheaver, a well-known and highly respected business consultant, has joined the Entrepreneurial Operating System® (EOS®) as a Professional Implementer. Sheaver will continue to serve as owner of St. Louis consulting firm Plus Delta and as a Fractional COO for a handful of select companies.

A business coach, facilitator and trainer with over 20 years of experience, Sheaver has consulted with Fortune 500 corporations but focuses the majority of her time…

3D Printing System Market Regional Outlook, Competitive Strategies, Factors Cont …

LOS ANGELES, United States: The research study presented in this report offers complete and intelligent analysis of the competition, segmentation, dynamics, and geographical advancement of the global 3D Printing System market. It takes into account the CAGR, value, volume, revenue, production, consumption, sales, manufacturing cost, prices, and other key factors related to the global 3D Printing System market. The authors of the report have segmented the global 3D Printing System…

Manual lubrication, flexible and ergonomic: EOS Move by Eckardt

Bretten/Germany, July 2019: Eckardt Systems, manufacturer of lubrication, cleaning and preservation systems for industrial production, introduces a new spray nozzle system for manual blank lubrication: EOS Move.

In comparision with conventional systems EOS Move swaps roles, since it is the spray bar that moves – not the blank. This enables the entire process – blank insertion, blank lubrication and blank removal – to be conducted requiring significantly less working space,…