Press release

cab applications on the fly: packing plant labels 140 broccoli per minute

Gebr. Hoff en Zonen prepares fresh broccoli from own cultivation for delivery to supermarkets. In the packing hall in Andijk, a maximum of 140 broccoli per minute are shrink-wrapped in foil, weighed, labeled and sorted fully automatically. The labeling solution has been developed by cab and the local integrator Tegra Systems.Until 2018, one conveyor line had been available to process broccoli. The new requirement was to add a second line to the plant and increase the output. André van Teeffelen, Sales Engineer at Tegra Systems, sums up: “The customer demanded solid technology that takes the work of the employees and operates quickly, precisely and error-free even in the longterm. The technology also collects all data that is of interest for the grower of the product, its customers in retail and wholesale, or the consumer. It contributes to the verification and traceability of broccoli as well as to food safety and quality”.

Custom labeling

For Gebr. Hoff en Zonen, Tegra Systems put into practice an automated plant to shrink-wrap broccoli in foil, weigh, label and presort the vegetables after they had been poured in the conveyor line. Two Hermes+ systems are installed on each conveyor line for printing and applying labels. The first one is printing product information clearly legible on labels and applies them rapidly on each wrapped broccoli: What vegetable is it, what is its weight, which its commercial category? Which retailer will be delivered? Pre-printed decoration labels are applied by the second Hermes+. Finally, the broccoli arriving in rapid succession on the conveyor belt are sorted to the correct weight section.

Each broccoli differs. As a consequence, the printing systems have to apply labels dynamically on different sizes and shapes within a conveyor line. Further critical factors are the uneven surfaces of foils in use to shrink-wrap vegetables, and the quick succession at which broccoli pass the labeling stations one after the other.

Full labeling

“Hermes systems”, André van Teeffelen says, “can be very well integrated to conveyor lines with the help of stands, assembly aids, sensors or switches. The firmware enables fast printer programming. A minimum of efforts is required to maintain the devices. All this is exactly what we need in our plants”. cab for Hermes systems provides a large number of accessorial modules to apply printed labels on products – by tamping, rolling or blowing on labels, corner-wrap, on round materials such as cables or pipes. Any possible task can be solved. This versatility is unique on the market. In the case of Gebr. Hoff en Zonen, Tegra Systems decided for the air jet box 6114. Labels printed by the Hermes print unit are sucked by a fan. A powerful blast of air makes labels overcome distances of about 20 cm to apply on the broccoli without surface contact. No pressure is exerted on the vegetables.

» For a video of the application see www.cab.de/en/hoff-tegra

About 200 kilometers away from Andijk, Pakstation Venlo sorts tomatoes, peppers, lemons and zucchini in nets or foiled packing. In the matter of labeling, two Hermes+ print and apply systems have been assembled in each packing line by the system integrator Zomerdam: one of the systems in classical manner, the other one upside down. By this, items in motion can be labeled from top and below. Pakstation Venlo aims in making 60 or 100 packings per minute instead of 30, if necessary. Thereby, labels have to be attached visibly and the information on the labels have to be clearly readable.

» For a video of this application see www.cab.de/en/pakstation-video

Presscontact: Guntram Stadelmann, cab Produkttechnik GmbH & Co KG, Wilhelm-Schickard-Str. 14, 76131 Karlsruhe, Phone: +49 721 6626-285, Fax: +49 721 6626-249, Email: g.stadelmann@cab.de

Portrait of the company: cab is Europe’s leading manufacturer of devices and systems to label individual components, units, products and packaging. Healthy global growth, both technical and functional lead and competent customer support are prior goals of the company. There are 400 employees in Germany and in seven subsidiaries abroad as well as 820 distribution partners in more than 80 countries to meet the targets. www.cab.de/en

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release cab applications on the fly: packing plant labels 140 broccoli per minute here

News-ID: 1897177 • Views: …

More Releases from cab Produkttechnik GmbH & Co KG

Outstanding innovative strength - cab Produkttechnik awarded TOP 100

- Selection process on the basis of more than 100 test criteria

- Fourth decoration since 2017

- Award ceremony to be held in June in Heidelberg

cab has once again been awarded TOP 100. This indicates that the company belongs to Germany's most innovative SME. Christian Wulff is going to congratulate cab face-to-face at the award ceremony during the German SME Summit on June 26, 2026, in Heidelberg. The former German Federal Minister and Lower…

Smart, flexible, cost-effective - print and apply solutions @LogiMAT 2026

Label printing systems by cab have been enabling reliable marking for more than 50 years. Industrial companies appreciate the wide range of possibilities in incoming goods and stock, picking and packing, transport and shipping. Smart and cost-effective options will complement tried and tested marking disciplines at the cab booth.

cab will be presenting labeling heads designed for applying pre-printed self-adhesive labels fully automatically in linear or rotary plants, synchronous to the…

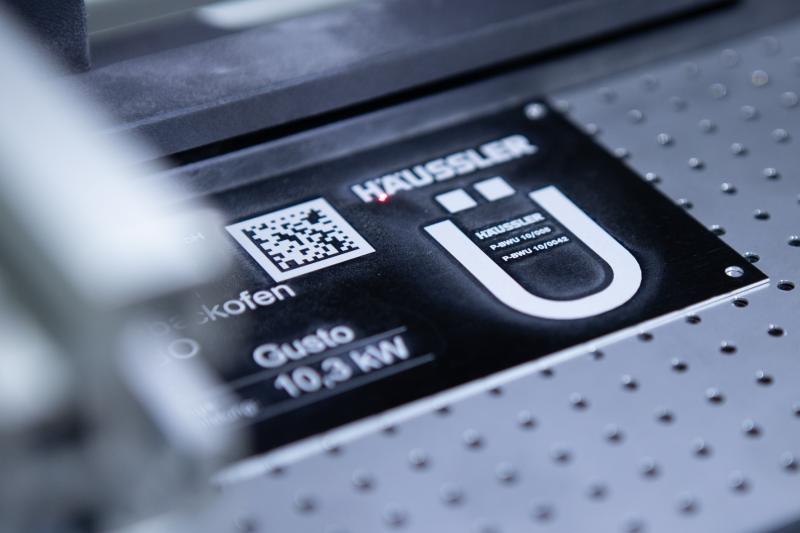

Tradition meets modern - Typeplate marking in a baking village

Karl-Heinz Häussler deals with grinding, kneading and baking. In the company's own baking village, around 100 employees design, manufacture and sell high-quality woodburning ovens and cookers, dough kneading machines, pasta makers and grain mills. Hobby bakers and professionals find guidance and inspiration in baking lessons and seminars. Every unit circulated by Häussler must be clearly identified in accordance with industry regulations. The typeplates are marked in reliable manner by cab…

cab and LRS unveil breakthrough label printing integration

cab and LRS have announced a major advancement in industrial label printing. As of the latest firmware 5.47.5 release, cab printers now fully support VPSX® bi-directional PJL delivery - unlocking a new era of precision, reliability, and flexibility for high-volume labeling environments.

This integration empowers organizations to streamline operations with intelligent label recovery and reprint capabilities. Whether due to a power outage or operator error, large batches of labels…

More Releases for Hermes

Asia Pacific Hermes Silk Sarees Market Set to Witness Massive Growth by 2032| Fe …

The Asia Pacific Hermes Silk Sarees market is estimated to be valued at USD 83.8 Mn in 2025 and is expected to reach USD 199.9 Mn by 2032, growing at a compound annual growth rate CAGR of 13.2% from 2025 to 2032.

➤ The latest Qualitative Research Report on the Asia Pacific Hermes Silk Sarees Market 2025, published by Coherent Market Insights, delivers in-depth insights into both global and regional markets,…

Il fondo d'investimenti Hermes-Sojitz lancerà la rete di hotel boutique Hermes …

Il fondo internazionale d'investimenti diretti Hermes-Sojitz ha iniziato di sviluppare la rete di hotel boutique Hermes Heritage Hotels. La collezione si comporrà di 12 alberghi situati nella parte nord dell'Italia. In futuro è previsto di uscire all’IPO e allargare la rete fino a 50 hotel boutique.

Il fondo internazionale d'investimenti diretti Hermes-Sojitz ha iniziato l'esecuzione del progetto di rete di hotels boutique Hermes Heritage Hotels. Alla fase iniziale collezione si comporrà…

Le fond d’investissement Hermes-Sojitz ouvre une chaîne des boutiques-hôtels …

Le fond international des investissements directs Hermes-Sojitz a commencé la réalisation du projet des boutiques-hôtels Hermes Heritage Hotels. Cette chaîne inclue 12 hôtels situés au nord de l’Italie. L’introduction en bourse est prévue aussi bien que l’extension du réseau jusqu’aux 50 boutiques-hôtels.

Le fond international d’investissement Hermes-Sojitz est en train d’élaborer le projet de la chaîne des boutiques-hôtels Hermes Heritage Hotels. Au début le réseau consistera de 12…

Hermes-Sojitz Investment Fund will launch new boutique hotels brand Hermes Herit …

Hermes-Sojitz International Investment Fund started implementing of new boutique hotels chain under Hermes Heritage Hotels brand. Collection will consist of 12 hotels located in the Northern Italy. The launch is expected in late 2018. In near future the fund is planning the expansion of the chain from 12 to 50 boutique hotels by attracting additional funding.

Hermes-Sojitz International Investment Fund started implementation of the boutique hotels chain project under the brand…

Hermes-Sojitz has launched the boutique hotels chain Hermes Heritage Hotels

Hermes-Sojitz international investment fund has launched its project of boutique hotels chain, Hermes Heritage Hotels. At the initial stage, the collection will include 12 unique hotels with 540 rooms located in the North of Italy. We are planning to enter the IPO and expand the chain to 50 boutique hotels.

The project involves renovation of historic Italian palazzos using the latest engineering technologies and modern design concepts of the best architectural…

Hermes Traducciones announces introduction of Plunet BusinessManager

Berlin/Madrid, 26 January 2010 – The Spanish translation company Hermes Traducciones has announced the introduction of Plunet BusinessManager as the company's central solution for business and translation management.

As one of the leading companies on the Iberian Peninsula with offices in Madrid and Malaga, Hermes consistently sets highest quality standards during the planning, management and controlling of translation projects.

"We decided to opt for Plunet because we had project management and…