Press release

Blechexpo 2019: Precision lubrication, corrosion protection, retrofitting for press shops

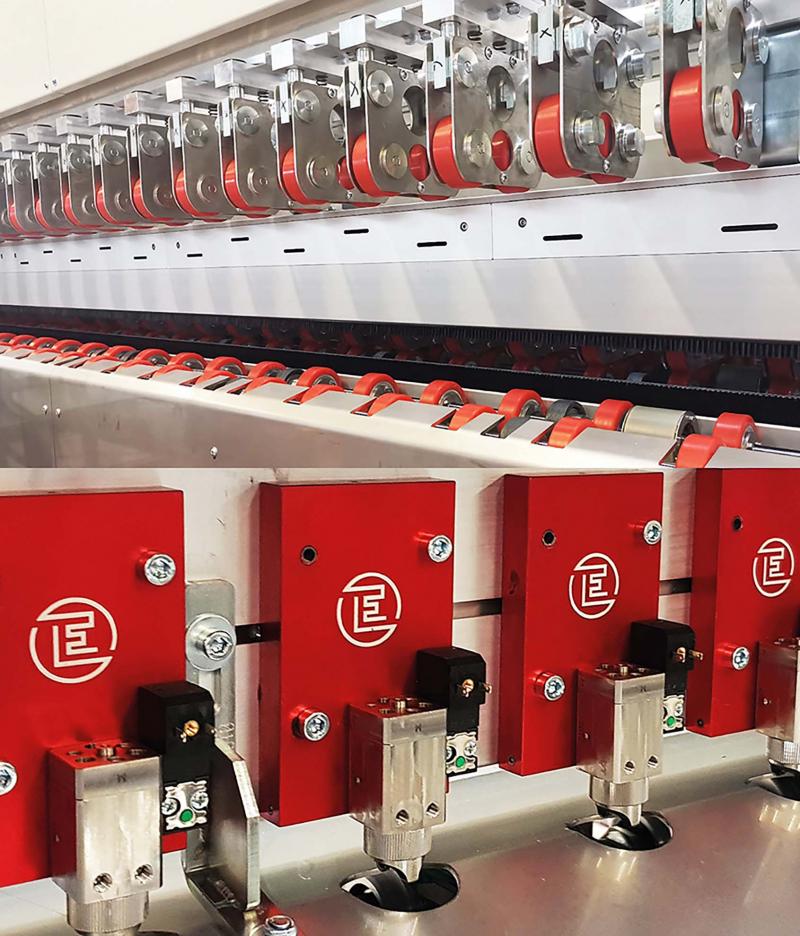

Bretten, Germany - Eckardt Systems highlights a variety of topics at the upcoming Blechexpo trade fair in Stuttgart. The specialist for lubrication, cleaning and preserving technology introduces a new control concept for its lubrication systems. The multifaceted issue of corrosion protection also takes center stage as do innovative retrofitting concepts for press shops. In addition, the company shows a budget version of the EOS spray lubrication system.The revised system control concept includes a touchscreen colour display and provides multilingual support. Interaction with the press line has been enhanced by a couple of featrues such as the automatic change of lubricant recipies and the communication of component and system malfunction. Among the many setup and control option addeds are the separate activation of spray patterns with regard to blank or coil widths and the individual control of the top and bottom stroke when roller lubrication systems are connected in series.

The spray chamber of the EOS X system for blank and coil widths of up to 2100 mm is also on display at Blechexpo. Eckardt positions the machine with its compact, robust design and streamlined functionality as a space saving, cost-effective solution among the EOS spray lubricator model range.

Retrofitting is another core which gets its share of attention in Stuttgart. Eckardt focuses on the combination and joint control of dry cleaning and spray lubrication and the substantial benefits it holds in store for the workflows in the press shop regarding process reliability, saving resources and overall work efficiency.

Eckardt makes the business segment of corrosion protection another focus of its participation at Blechexpo. The company offers solutions for the protection of components with exposed metal parts following the hot forming process as well as for the coating of parts following welding and riveting. Purpose-built hybrid systems provide electrostatic spraying which makes the oil adhere much better to perpendicular or cylindrically shaped surfaces. In comparison with competitive products the Eckardt corrosion protection systems include a larger spraying chamber with more spray nozzles distributed across the whole width, so that all areas even of the most individually shaped surfaces can be reached.

Press contact:

Stefan Müller-Ivok

Marketing & Communications Manager

Eckardt Systems GmbH

Westliche Gewerbestr. 2

75015 Bretten

Germany

M: +49 176 5791 2240

T: +49 7252 9420-0

s.mueller-ivok@eckardt-systems.com

Founded in 1992 Eckardt Systems manufactures lubrication systems as well as cleaning and preservation systems for industrial production. Today, the second generation of this family-run company employs some 30 people.

The product range includes roller lubricators, squeeze-on lubricators and spray systems, available in different versions for different widths of materials. Eckardt also produces oil mist separators and complete systems to customer-specific specifications. as well as customized systems, for example for hydroforming (IHU). In addition, the company offers numerous spray and spit nozzles as well as dosing systems for the lubrication segment. We also supply lubricants and oils under our own brand name ROTOL.

Furthermore, Eckardt serves the process field preserving with corrosion protection systems, which are used primarily in the hot forming process as well as to prepare parts and assemblies for transport. The dry cleaning systems for sheet metal and blanks offer an economical, environmentally-friendly low maintenance alternative to the wet cleaning systems often in use.

Eckardt produces all of its systems and plant at the company headquarters in Bretten, near Karlsruhe, Germany. The depth of our in-house manufacturing capabilities is widely recognized. We run our own electronics development department as well as a nozzle testing laboratory dedicated to optimizing spraying processes and performing fault analyses in customer systems.

Eckardt offers its customers comprehensive advice on all aspects of the lubrication process beginning with an extensive survey of the production environment through to the best-possible integration in upstream and downstream process steps. In the field of engineering Eckardt technology is adapted to precisely suit existing conditions and processes on site and can be individually modified to meet requirements. Installation, commissioning and general system refurbishments round off the spectrum.

The company serves customers in all regions of the world. We focus on the automotive and supplier industries; however, small companies offering sheet metal punching services also profit from our know-how as manufacturer of quality products.

www.eckardt-systems.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Blechexpo 2019: Precision lubrication, corrosion protection, retrofitting for press shops here

News-ID: 1852136 • Views: …

More Releases from Eckardt Systems GmbH

Manual lubrication, flexible and ergonomic: EOS Move by Eckardt

Bretten/Germany, July 2019: Eckardt Systems, manufacturer of lubrication, cleaning and preservation systems for industrial production, introduces a new spray nozzle system for manual blank lubrication: EOS Move.

In comparision with conventional systems EOS Move swaps roles, since it is the spray bar that moves – not the blank. This enables the entire process – blank insertion, blank lubrication and blank removal – to be conducted requiring significantly less working space,…

More Releases for Eckardt:

Back to Life: A Journey of Resilience, Healing, and Transformation

Tim Wurfel's 'BACK TO LIFE' project transforms personal adversity into a global mission of resilience and rehabilitation, offering hope, holistic healing, and accessible recovery tools for stroke and cancer survivors.

Image: https://lh7-rt.googleusercontent.com/docsz/AD_4nXf6jZpVEtBnokE334DAV_UulfewPISyNomAEEMX9dllsNU8YC87bDv1Jag_3U4Qqx19R4qjT1gCl80loHDBrSaRcDGfhlBhWKa8OE0BCSaseWh-H7RWKypAHMBMbbNJX37qOYrb33T236FnPD5LCXE?key=y8I2snP2rJWKGTQsQ7Smdw

"If you have hope, you have everything you need." These words define the mission of Tim Wurfel, a man who has transformed his personal journey of struggle, recovery, and self-discovery into a movement that inspires and empowers others facing similar…

Global Hollow Cone Spray Nozzles Market to Witness a Pronounce Growth During 202 …

Market Research Report Store offers a latest published report on Hollow Cone Spray Nozzles Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report.

The Hollow Cone Spray Nozzles market was valued at xx Million US$ in 2018 and is projected to reach xx Million US$ by 2025, at a CAGR of xx% during the forecast period. In this study, 2018 has…

Flat Fan Spray Nozzles Market Size, Share, Development by 2024

Global Info Research offers a latest published report on Flat Fan Spray Nozzles Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. This report focuses on the key global Flat Fan Spray Nozzles players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Flat Fan Spray…

Hollow Cone Spray Nozzles Market Size, Share, Development by 2024

Global Info Research offers a latest published report on Hollow Cone Spray Nozzles Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. This report focuses on the key global Hollow Cone Spray Nozzles players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Hollow Cone Spray…

Solid Stream Spray Nozzles Market Size, Share, Development by 2024

Global Info Research offers a latest published report on Solid Stream Spray Nozzles Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. This report focuses on the key global Solid Stream Spray Nozzles players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Solid Stream Spray…

Manual lubrication, flexible and ergonomic: EOS Move by Eckardt

Bretten/Germany, July 2019: Eckardt Systems, manufacturer of lubrication, cleaning and preservation systems for industrial production, introduces a new spray nozzle system for manual blank lubrication: EOS Move.

In comparision with conventional systems EOS Move swaps roles, since it is the spray bar that moves – not the blank. This enables the entire process – blank insertion, blank lubrication and blank removal – to be conducted requiring significantly less working space,…