Press release

Selection of the best control valve for flotation column and cell control

Froth depth in a flotation cell is an excellent indicator of flotation cell performance. The thicker the froth the more concentrate is entrained within. There are several factors which influence control such as air addition rate, flocculant dosing rate and pulp flow rate. Balancing the circuit is almost impossible without accurate and reliable control.There are a various types of valves which can be utilized in flotation column and flotation cell control. The type of valve used on flotation columns may vary from a flotation cell. For example dart valves have been traditionally utilized on flotation cells. In larger mining operations the sizes of flotation cells have grown and so must the size of the valves. In certain designs the dart valve may require an external box built onto the exterior of the flotation cell, which may be large and costly to manufacture. Another hindrance is that the containment box may need to be drained to allow maintenance on the dart valve.

There are alternate types of valves that do not require the dart valve containment box which may allow for a less expensive total assembly and provide accurate and reliable control of the flotation cells. Although, the low driving head in flotation cells may create challenges in selection of the control valve size. For this reason, control valve sizing on flotation cells requires more consideration of piping effects. Inlet and outlet velocities from the cells as well as any 90 degree turns or elbows at the outlet may play a significant role in decreasing the driving head and thus force the selection of a larger diameter control valve. Control valve sizing in flotation cells requires more consideration of piping effects due to the low driving head. The ultimate goal is accurate flow control to maximize pulp retention time and minimize downtime. Some manufacturers have developed special sizing programs that automatically calculate the decreased driving head caused by elbows, bends, inlet and outlet tank effects.

Pinch valves have been utilized successfully in small and large sizes to eliminate the need for external boxes and additional material costs. The pinch valve provides very accurate flow control and a very long service lifetime.

One valve in worth of mentioning is a pinch valve is located at Boliden Aitik copper mine. It has been continuously operating without a rubber sleeve change for 22 years. This is the oldest know reference for a Larox valve installed on flotation control.

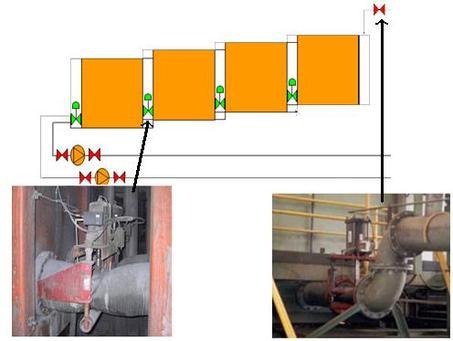

Figure attached depicts the valve located on the outlet of the last cell.To insure the last valve will not cavitate the piping is shaped like a J before it departs to its final destination. This J section creates a few feet of head pressure to insure the full pressure drop is not taken across the valve. It is simple inexpensive manner to insure the prevention of cavitation. Cavitation can cause short sleeve lifetime and unpredictable control due to the pulsing effects of cavitation.

In flotation columns the design of the outlet piping may or may not have severe effects on the control valve utilized to control the level in the column. If the column is 30 feet in height then the driving head is the pressure created by the head times the specific gravity. In most cases the driving head is sufficient enough that a simple calculation can be made to determine the size of valve required and Cv without any special sizing program to calculate downstream piping effects. However if the valve is required to take the full pressure drop across it then there is a high risk of cavitation. Again the J tube arrangement should be employed to create some back pressure on the control valve to limit the amount of pressure drop the valve must take and prevent cavitation from occurring across the valve. In a flotation column a J tube that is 50% of the column height with a vacuum breaker at the top will provide adequate protection to prevent cavitation.

The rule of thumb with a pinch valve is to limit the pressure drop across the valve to 50% of the inlet pressure to the valve. If you do this in most cases then the valve will not cavitate.

Larox Flowsys Group has more than 100 employees and the number is growing. Headquartered in Lappeenranta, Finland Larox Flowsys Group has subsidiaries in Linthicum, Maryland (USA), Sydney (Australia) as well as in Kouvola (Finland). As almost 80% of the company's net sales come from global exports, the reliable and fast customer service is guaranteed by an international sales and service network, covering over 55 countries.

To learn more about Larox Flowsys and its expanded product offerings and brands, visit www.larox.fi.

Press Information:

Larox Flowsys Oy

Marssitie 1

P.O.Box 338

53101 Lappeenranta

Finland

Contact Person:

Helena Byckling

Communication Manager

Phone: +358 201 113 311

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Selection of the best control valve for flotation column and cell control here

News-ID: 181237 • Views: …

More Releases from Larox Flowsys

Proven Performance by Renewed Larox Flowsys

Larox Flowsys, the worldwide supplier of flow control and pumping solutions has decided to change its name to Flowrox. The visual look and feel will also be renewed. The new name will be taken into use in mid September and the new outlook will replace the existing gradually by January 1st, 2012.

The reason behind the significant renewal of the corporate brand and image is the recent acquisition of Larox Oyj…

More Releases for Valves

Bronze Valves Market 2019 | Worldwide Market Outlook 2025 | Major Manufacturers …

Bronze Valves Market research report delivers a close watch on leading competitors with strategic analysis, micro and macro market trend and scenarios, pricing analysis and a holistic overview of the market situations in the forecast period.

Get Exclusive FREE Sample Copy Of this Report @ https://www.upmarketresearch.com/home/requested_sample/68107

UpMarketResearch offers a latest published report on “Global Bronze Valves Market Analysis and Forecast 2019 - 2025” delivering key insights and providing a competitive advantage to…

Latest research on Swing Check Valves in Industrial Market With top key players …

Up Market Research offers a latest published report on “Global Swing Check Valves in Industrial Market Research Report 2019” delivering key insights and providing a competitive advantage to clients through a detailed report. The report contains 97 pages which highly exhibit on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing and profitability.

Request Sample Copy Of this Report @ https://www.upmarketresearch.com/home/requested_sample/68059

Swing Check Valves in Industrial Market research…

Plastic Ball Valves Market Comprehensive Analysis | Key Players - Johnson Valves …

The plastic ball valve is a push-fit connection solution of plastic and copper pipe.The global Plastic Ball Valves market is valued at xx million US$ in 2018 is expected to reach xx million US$ by the end of 2025, growing at a CAGR of xx% during 2019-2025.

This report focuses on Plastic Ball Valves volume and value at global level, regional level and company level. From a global perspective, this report…

Global Flanged Globe Valves Market Insights, Size, Share, Key-Players: Johnson V …

A newly compiled business intelligent report, titled “Global Flanged Globe Valves Market” Insights, Forecast to 2025 has been publicized to the vast archive of Market Research Hub (MRH) online repository. The study revolves around the analysis of Flanged Globe Valves Market, covering key industry developments and market opportunity map during the mentioned forecast period. This report further conveys quantitative & qualitative analysis on the concerned market, providing a 360 view…

Global Subsea Valves for Oil and Gas Market Outlook, Growth By Top Manufacturers …

Researchmoz added Most up-to-date research on "Global Subsea Valves for Oil and Gas Market Outlook, Growth By Top Manufacturers - Oliver Valves, Alco Valves, BEL Valves and Petrol Valves" to its huge collection of research reports.

As oil and gas becomes more difficult to extract from high pressure ultra-deep oceans and high temperature, the continuous reliability of subsea valve is of the most importance.

The Subsea Valves for Oil and Gas market…

Global Aerospace Valves Market 2018 By Trend, Market Players, Valves, Mechanism …

Global Aerospace Valves Market 2018-2023:

Global Aerospace Valves market size will grow from in 2017 to by 2023, at an estimated CAGR of xx.xx%. The base year considered for the study is 2017, and the market size is projected from 2018 to 2023.

The growth can be attributed to the increasing aircraft orders as a result of the rise in air passenger traffic across the globe. The growth in passenger traffic is…