Press release

TBT: Tool shanks with interior cooling – a challenging drilling task

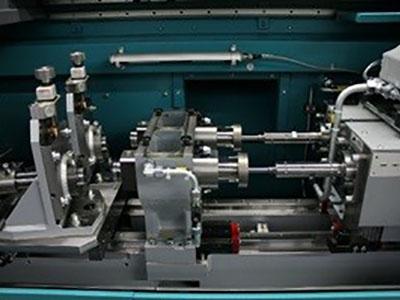

TBT develops a special device for standard deep hole drilling machine with four degrees of freedom.Cutting tools increasingly work with an interior cooling system. Manufacturing of such tool shanks becomes a challenge because cooling channels with a high length-to-diameter ratio have to be drilled. For some variants, the tool designers even intend drilling of inclined holes. For such drilling tasks, TBT Tiefbohrtechnik, located at Dettingen/Erms, has developed a special device to drill with single lip drills.

If the task only were to drill centric cooling channels, this would be a simple, hardly appreciable task. But tool shanks have become complex workpieces, since the cooling lubricant must be optimally fed to the edges of the drilling or milling tool. Therefor a centric cooling hole is not sufficient. As a result, one manufacturer of such shanks was confront-ed with increasing requirements. This manufacturer had to produce several variants of shanks, with different shank lengths and diameters, as well as versions with eccentric holes, sometimes running inclined to the workpiece middle axis and in various distances to the middle axis. The diameters of the coolant holes vary with each tool for which they are intended, ranging mostly from 1.5 to 6 mm. This results in rather large length-to-diameter ratios. The technology of deep hole drilling with singlelip drills is best suitable for this task, as singlelip drills are much better than conventional spiral drills regarding deviation and straightness and hence mostly the better tools with regards to process reliability.

Since the manufacturer of the tool shanks was already using several deep hole drilling machines type ML200 from TBT Tiefbohrtechnik in Dettingen/Erms, he wanted to produce the new workpiece variants again on this machine type. The machine is perfectly suited for tool shank applications. It is provided by TBT with one or several spindles, corresponding to drilling diameters of 0.8 to 12 mm. In this way, flexibility in both directions is given, if the diameter range from 1.5 to 6 mm is not sufficient.

TBT Tiefbohrtechnik from Dettingen/Erms not only manufactures machines but is also contact partner for all questions around deep drilling. This also applies for devices. As a consequence, this tool shank manufacturer requested a suitable solution from TBT which could be adjusted to the new, different workpiece versions and fit exactly with the intended ML200 in a two-spindle variant.

For the specialists at TBT, designing devices is a daily business. However, providing a highly flexible solution in this instance was a challenging task. In detail: The drilling device had to provide four degrees of freedom: 360° rotation of the workpiece around the middle axis, height adjustment, cross adjustment and angle adjustment for the inclined holes in horizontal direction. Cross and angle adjustment could be synchronous for both spindles. However, the rotation and height adjustment for both workpieces had to be adjustable separately for each spindle. Andreas Schlegel, Sales Manager at TBT: “Our claim is, to supply complete and 100% functioning solutions, consisting of deep hole drilling machines, drilling tools and all other machinery components. Beside this devices, that may include components for automatized production. In this case, the customer decided against an automatized solution due to cost reasons and commissioned us to install a manual device.”

Frequently, the diameters of the coolant holes in a tool shank differ (see Fig: d1, d2). For drilling from both sides, the user embrace the workpiece. A stop ensures exact positioning. A clamping screw fixes the cylindrical shanks, which are equipped with a milled groove for this purpose. In the shown variant the drilled hole with d1 proceeds inclined and outside of the middle axis. In the mid of the workpiece, it meets the drill hole with d2 which is also eccentrically positioned but parallel to the middle axis.

The difficulty: The slanted d1 drill hole must meet the d2 drill hole exactly at this position to prevent improper cross-sectional constriction.

Due to significant varying drilling depths of the different workpiece variants, the manufacturer uses the drill bush carrier in two ways: For depths up to approx. 200 mm, immersion sleeves are used which realize the contacting movement of the drill bushes to the workpiece by using springs. For higher drilling depths, the user disassembles the immersion sleeves and uses a sealing case. In this case, there is also the possibility of installing a tool steady for the support of the deep hole drilling tools.

All in all, an example for the high art of fixture construction. “Our solution quite includes a lot of ingenious details,” says Andreas Schlegel. “All deflections can be adjusted quite simple and with the sufficient precision in using either scales or digital displays.” Since even small angle deflections will cause a large transverse offset in long workpieces, the available space in the ML200 was initially a hot topic of discussion. However, the engineers were able to combine all the requirements, quality and available space. The customer didn’t have to invest into a larger machine - which was one of his main issues. “And for all drilling processes, the standard safety guard can still be closed,” Andreas Schlegel adds with a smile.

PressCo. The Press Company

Yvonne Nagel

Hindenburgstr. 56

72622 Nürtingen

Germany

Phone +49 (0) 7022 90 39 - 73

yvonne.nagel@pressco.de

www.pressco.de

History - TBT Tiefbohrtechnik GmbH + Co…

...Founded in 1966 in Dettingen on the Erms, Germany, specialising from the start in the niche competency of “Deep Drilling“. Thanks to this future-oriented manufacturing technology, the company was able to develop in the critical customer sectors over a relatively short period of time. The strategy of supplying machines, tools and services from a single source proved to be a decisive factor in terms of competitiveness. The fact that the company was able to develop so quickly can be attributed to three criteria for success which lie at the heart of company policy:

· The quality of its products, which benefits customers in terms of high process safety and low risk of failure.

· The high level of precision which these machines exhibit while in operation.

For the customer, this can be seen in the optimal manufacturing results obtained, enabling them to become a price / quality leader in their commercial markets.

· Keeping close to customers, which allows TBT to recognize their clients’ problems and develop specific solutions for these issues.

This unique approach, which has proved decisive in terms of competitiveness, has helped TBT win, not just in the German market. Demand has grown both from within Europe and even from other continents. TBT has reacted to this demand by building a global distribution network and now has subsidiaries and representation from the USA to China, in every industrialised country in the world. The reputation which TBT enjoys amongst its customers is based, above all else, on their engagement and flexibility as well as their ability to innovate when making client projects a reality. This had led to TBT’s position as worldwide market leader in the deep drilling sector.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release TBT: Tool shanks with interior cooling – a challenging drilling task here

News-ID: 1811327 • Views: …

More Releases for TBT

TBT Ballers SoCal: Elevating Youth Baseball to New Heights in Southern Californi …

San Diego, CA - TBT Ballers SoCal proudly announces its official launch as the next evolution of the acclaimed MVP Hustle Clinger program. This transformation preserves the program's legacy while introducing exciting opportunities for athletes to develop their skills through personalized coaching, team camaraderie, and elite-level competition.

Under the leadership of Grant Clinger, founder and director of MVP Hustle Clinger, TBT Ballers SoCal maintains the same dedicated teams, coaching staff, and…

Deep Hole Drilling Market Is Booming Worldwide 2021-2028 | Top Key Players - …

𝐋𝐎𝐒 𝐀𝐍𝐆𝐄𝐋𝐄𝐒, 𝐔𝐧𝐢𝐭𝐞𝐝 𝐒𝐭𝐚𝐭𝐞𝐬 : The Global Deep Hole Drilling market size is evaluated through revenue (US$) as well as production volume for this research. The Deep Hole Drilling market report also analyzes major segments and the geographical distribution across the world. The report even contains a wide range of Deep Hole Drilling market dynamics including restrictions, future prospects of each segment and growth drivers. Based on these factors, the…

Deep Hole Drilling Market Business Opportunities 2026 - Top Companies are TBT, M …

The Global Deep Hole Drilling Market analysis report published on IndustryGrowthInsights.com is a detailed study of market size, share and dynamics covered in XX pages and is an illustrative sample demonstrating market trends. It covers the entire market with an in-depth study on revenue growth and profitability. The report also delivers on key players along with strategic standpoint pertaining to price and promotion.

Get FREE Exclusive PDF Sample Copy of This…

Cctv Video Camera Market to Witness Huge Growth by 2025| Rugged Marine, Orlaco, …

HTF MI recently introduced Global Cctv Video Camera Market study with in-depth overview, describing about the Product / Industry Scope and elaborates market outlook and status to 2023. The market Study is segmented by key regions which are accelerating the marketization. At present, the market is developing its presence and some of the key players from the complete study are Rugged Marine, Orlaco, TBT, Shivision, Synectics Industrial Systems, Siqura B.V,…

Deep Hole Drilling Market to 2025 - Top Companies are Atlas, Kays Engineering, S …

UpMarketResearch offers a latest published report on “Global Deep Hole Drilling Market Industry Analysis and Forecast 2018-2023” delivering key insights and providing a competitive advantage to clients through a detailed report. The report contains 136 pages which highly exhibits on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing and profitability.

Download PDF sample report @https://www.upmarketresearch.com/home/requested_sample/2819

Deep Hole Drilling market research report delivers a close watch on…

Global CCTV Video Cameras Market Outlook 2018 Siqura B.V, ACESEE Security, TBT, …

Recently added detailed market study "Global CCTV Video Cameras Market" examines the performance of the CCTV Video Cameras market 2018. It encloses an in-depth Research of the CCTV Video Cameras market state and the competitive landscape globally. This report analyzes the potential of CCTV Video Cameras market in the present and the future prospects from various angles in detail.

The Global CCTV Video Cameras Market 2018 report includes CCTV Video Cameras…