Press release

RobotStudio Palletizing PowerPac highlights expanded ABB palletizing portfolio unveiled at Interpack 2011 in Germany

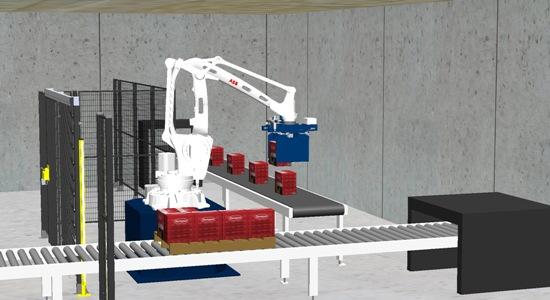

AUBURN HILLS, Mich. (June 9, 2011) – ABB Robotics, a leading supplier of industrial robots, introduced a comprehensive range of new palletizing products at Interpack 2011, May 12-18 at the Düsseldorf Fairgrounds in Germany. The new offerings include two new palletizing robots and three new palletizing grippers. The most revolutionary aspect of the expanded palletizing portfolio, however, is the Palletizing PowerPac for RobotStudio, a powerful new programming software that merges the features and benefits of a graphic system simulation tool with application programming software.“The new palletizing robots and grippers have been designed and validated to be performance leaders in their respective classes, but the most significant aspect of the introduction is the Palletizing PowerPac,” said Rick Tallian, consumer industry manager, ABB Robotics. “We have integrated our proven PickMaster 5 palletizer programming technology into the ABB RobotStudio simulation environment. The result is the ability to create a fully simulated robotic palletizing program that can also be downloaded directly to a robotic system on the factory floor.”

In creating the new Palletizing PowerPac ABB greatly simplified the task of programming complex robotic palletizing applications; providing a programming software that will allow users to configure, simulate and program ABB robots and grippers for palletizing solutions in one step, with little or no robot programming experience required. Following the PickMaster theme the new Palletizing PowerPac automatically generates a proven RAPID application program utilized to command the activities of the robot. What used to take days will now take minutes. It will also allow potential users to validate the performance of their palletizing system before risking any equipment investments.

“Robotic palletizing systems are often very complex, configured to handle multiple incoming container configurations and pallet patterns. This makes it difficult to evaluate system performance and determine if the robot can reach all pick and place locations within the work cell,” said Tallian. “With the new PowerPac these performance factors can be accurately evaluated during the conceptual phases of the project.”

RobotStudio allows the designer to accurately locate the position of multiple product infeed conveyors, pallet build positions, pallet handling conveyors, robot safety enclosures and other physical barriers present in the manufacturing facility. Once the system layout is established the correct robot can be selected for the application. The entire range of ABB robots is available for validation testing in the simulated application.

To complete the system design ABB’s new FlexGrippers are also modeled in the PowerPac module. The FlexGrippers are fully functional in the program to provide more accurate results for system performance. Once the system is configured, all incoming product configurations and pallet patterns are entered into the PowerPac to evaluate performance. The fully functional simulation is not only visually impressive, but very accurate, providing an excellent tool for demonstrating the system’s operation to end-user engineering teams and management.

One of the most popular interactive exhibits at Interpack 2011 was the “Five Minute Challenge” held at the ABB Robotics booth. Several hundred show attendees experienced firsthand the strength of the new PowerPac software by taking various product configurations and defining and programming them into a fully functioning palletizing cell in five minutes or less.

“We are excited about the entire portfolio of new palletizing products, but what brings it all together is the new Palletizing PowerPac,” said Joe Campbell, vice president of the ABB Robot Products Group in the US. “It will make the entire process of setting up and running a palletizing system easier and more economical - easier to use and easier to update, while significantly reducing engineering time and the cost of implementation.”

In addition to the PowerPac the other palletizing products introduced at Interpack 2011 were:

- The compact IRB 460, the fastest known palletizing robot on the market. Capable of up to 2,190 cycles per hour, this 4-axis robot is perfect for high-speed end-of-line palletizing and bag palletizing of products that weigh up to 50 kilograms.

- The IRB 760 designed for high-output, full-layer palletizing. Boasting an impressive payload capacity of 450 kilograms and a reach of 3.2 meters, this 4-axis robot features a high inertia wrist – double that of competitors – that enables it to rotate heavier and larger products faster than any other robot.

- Three FlexGripper end-of-arm tools round out the new hardware product offerings, including a heavy-duty claw for high-speed bag palletizing, a vacuum gripper for light and medium weight cases, and clamp gripper for handling heavy cases.

In conjunction with the existing palletizing products ABB now offers a complete portfolio of robotic products to service end-of-line, centralized, full layer and bag palletizing applications.

About ABB

ABB (www.abb.com) is a leader in power and automation technologies that enable utility and industry customers to improve their performance while lowering environmental impact. The ABB Group of companies operates in around 100 countries and employs about 124,000 people.

About ABB Robotics

ABB Robotics (www.abb.com/robotics) is a leading supplier of industrial robots – also providing robot software, peripheral equipment, modular manufacturing cells and service for tasks such as welding, handling, assembly, painting and finishing, picking, packing, palletizing and machine tending. Key markets include automotive, plastics, metal fabrication, foundry, electronics, pharmaceutical and food and beverage industries. A strong customer focus helps manufacturers improve productivity, product quality and worker safety. ABB has installed more than 190,000 robots worldwide.

ABB Robotics

1250 Brown Road

Auburn Hills,

MI - 48326

Alex Miller

alexm@aem-mg.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release RobotStudio Palletizing PowerPac highlights expanded ABB palletizing portfolio unveiled at Interpack 2011 in Germany here

News-ID: 179746 • Views: …

More Releases from ABB Robotics

YuMi® - the future of human-robot collaboration

London/Zurich, September 9, 2014 – ABB has unveiled the world’s first truly collaborative robot: YuMi®.

YuMi is a human-friendly dual arm robot designed for a new era of automation, for example in small parts assembly, where people and robots work hand-in-hand on the same tasks. YuMi is short for ‘you and me,’ working together.

YuMi has been developed to meet the flexible and agile production needs of the consumer electronics…

New small robot family addresses the needs of modern material handling and machi …

With the introduction of the IRB 1200 ABB addresses the needs of the material handling and machine tending industries for flexibility, ease of use, compactness and short cycle times while still maintaining large working envelopes.

“We are excited to introduce the IRB 1200,” says Phil Crowther, Small Robots Product Manager. “Our exhaustive market analysis and development process has resulted in a robot that is incredibly compact, allowing for maximization of useable…

More Releases for PowerPac

Global Smart Mosquito Repellent Market: Revolutionizing Pest Control with Intell …

Smart Mosquito Repellent Market

The global Smart Mosquito Repellent market was valued at US$ million in 2023 and is anticipated to reach US$ million by 2030, witnessing a CAGR of % during the forecast period 2024-2030.

Get Free Sample: https://reports.valuates.com/request/sample/QYRE-Auto-12X15694/Global_Smart_Mosquito_Repellent_Market_Research_Report_2023

Trends:

1. Rise of IoT Integration: Increasing adoption of IoT-enabled mosquito repellents that allow remote control and automation.

2. Demand for Eco-friendly Solutions: Growing preference for non-toxic and chemical-free repellents.

3. Advancements in Ultrasonic Technology: Enhanced efficiency through soundwave-based…

Electric Wheelbarrow Market: Competitive Dynamics & Global Outlook 2024

Market Research Report Store offers a latest published report on Electric Wheelbarrow Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report.

According to this study, over the next five years the Electric Wheelbarrow market will register a 2.3% CAGR in terms of revenue, the global market size will reach US$ 245.4 million by 2024, from US$ 224.2 million in 2019. In…

Global Electric Wheelbarrow Market to Witness a Pronounce Growth During 2023

New report published by Market Research Report Store (MRRS) which offers insights on the global Electric Wheelbarrow market.

Electric wheelbarrow is an improve type of wheelbarrow. It enables one worker to transport heavy loads across worksites with minimal effort. Electric wheelbarrow is widely used in industrial application, office application, household application and other application fields.

Click to view the full report TOC, figure and tables:

https://www.marketresearchreportstore.com/reports/2778/global-electric-wheelbarrow-market

Global Electric Wheelbarrow Market: Forecast by Type…

Electric Wheelbarrow Market Report 2018 Companies included Muck Truck, Overland, …

We have recently published this report and it is available for immediate purchase. For inquiry Email us on: jasonsmith@marketreportscompany.com *********

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the year 2018 to 2025, etc. The report also provides…

Global Electric Wheelbarrow Consumption Market 2017 - Muck Truck, Overland, SCHM …

Global Electric Wheelbarrow Consumption Market Report 2017 presents a professional and deep analysis on the present state of Electric Wheelbarrow Consumption Market 2017.

In the first part, Electric Wheelbarrow Consumption Market study deals with the comprehensive overview of the Electric Wheelbarrow Consumption market, which consists of definitions, a wide range of applications, classifications and a complete Electric Wheelbarrow Consumption industry chain structure. The global Electric Wheelbarrow Consumption market analysis further consists…

Electric Wheelbarrow Market 2017- Muck Truck, Overland, SCHMID Group, Sherpa Too …

Electric Wheelbarrow Market 2017 Industry research report provides important information to identify and analyze the market need, market size and competition. This market research report used in maintaining competitiveness over competitors.“Electric wheelbarrow is an improve type of wheelbarrow. It enables one worker to transport heavy loads across worksites with minimal effort. Electric wheelbarrow is widely used in industrial application, office application, household application and other application fields.

Scope of the Report:

This…