Press release

Compounding World Expo 2019: SCHWING Technologies presents its thermal cleaning systems for machine parts and tooling

Neukirchen-Vluyn (Germany), April 25, 2019. Plastic additives and compounding are the central topics of Compounding World Expo in Cleveland, Ohio on May 8-9, 2019. As a supplier of thermal cleaning systems, the German company SCHWING Technologies GmbH, together with its subsidiary SCHWING Technologies North America Inc., will also be exhibiting at the international trade show. With their cleaning systems, all polymers and plastic additives can be easily removed from machine parts and tooling. At booth A814, Thomas Schwing (Managing Director), along with Michael J. Robinson (Engineering & Process Technology) and Andrew S. Dickinson (Sales Manager) will inform attendees about the special features and advantages of the SCHWING systems. “Our intelligent systems not only clean reliably and safely, they also guarantee residue-free cleaning results,” emphasizes Thomas Schwing, building on 50 years of practical experience. Since 1969, the company has been the technology leader and international specialist for thermal cleaning solutions from its headquarters in Neukirchen-Vluyn, Germany. Since the beginning of the year, customers in the US and Canada have also benefited from SCHWING experts in the American office—based in Princeton, New Jersey.Thermal cleaning systems

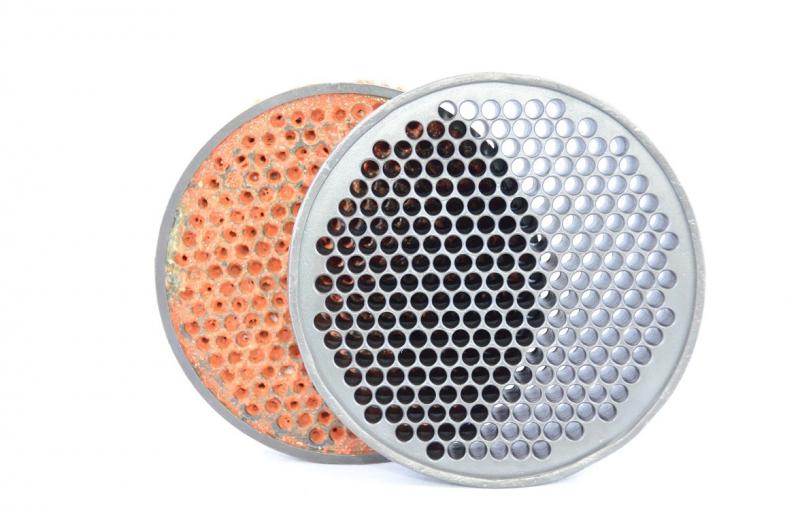

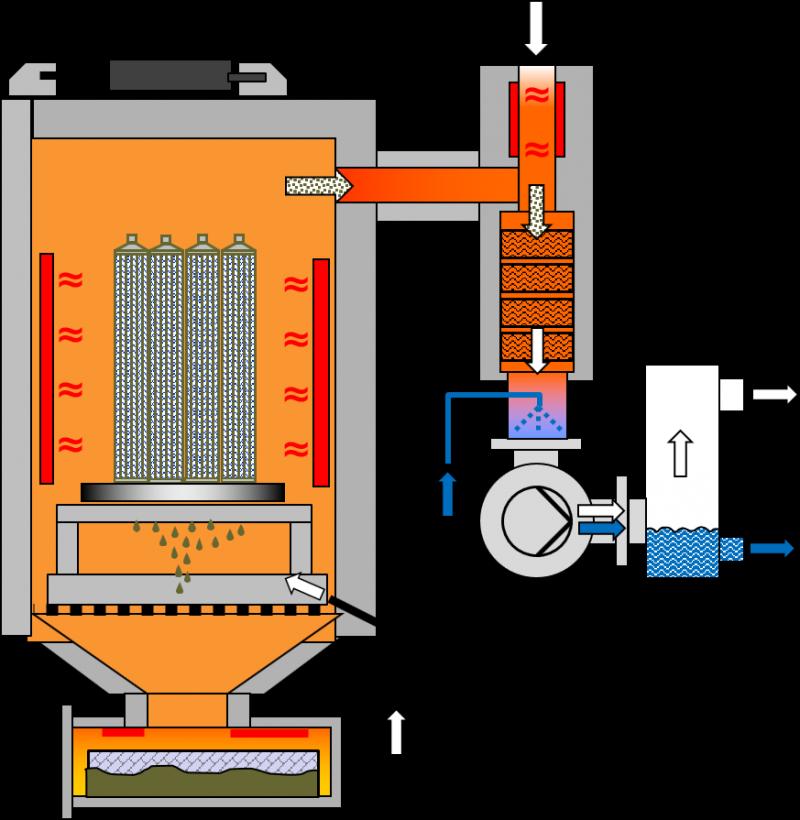

To its customers in the compounding industry, SCHWING recommends three different systems for all types of polymers and plastic additives. They guarantee perfect cleaning results with the user-friendly and precisely controlled VACUCLEAN, INNOVACLEAN and MAXICLEAN systems as well as post treatment equipment. All systems are energy-efficient and are environmentally friendly. “Our systems clean extremely gently and reliably,” explains Michael J. Robinson. “We thermally decompose polymer contamination and protect the metallurgy of the part.” The gentle vacuum pyrolysis systems (VACUCLEAN) are the ideal solution for cleaning pelletizing dies, screws and screw elements. Fluidized bed systems (INNOVACLEAN) are perfectly suited for all polymers, including high-temperature plastics such as LCP, PEI, PPS and PI. The SCHWING team uses these systems primarily for cleaning breaker plates and screw elements. The pyrolysis furnaces (MAXICLEAN) also clean large tools and components, such as large melt pumps and heat exchangers, by thermal oxidation. Andrew S. Dickinson knows that this results in numerous advantages for customers: “Using our thermal cleaning systems significantly increases machine tooling availability. This, in turn, saves time and money and increases productivity for compounders.”

Further information on thermal cleaning solutions from SCHWING: https://www.thermal-cleaning.com/en/applications-and-industries/plastics-production.html

Keywords: Thermal cleaning, plastic removal, plastics additives, compounding, masterbatch, Schwing Technologies, Schwing Technologies North America Inc.

SCHWING Technologies

SCHWING Technologies has been operating for 50 years and is the worldwide technological leader for high-temperature systems for thermal cleaning, thermo-chemical finishing and heat treatment of metal parts and tools. The owner-managed company designs, manufactures, and operates systems at its headquarters in Neukirchen-Vluyn in Germany's Lower Rhine region. Built upon the achievements of German engineering, the medium-sized business is globally the best-known specialist in the removal of plastics. Among SCHWING’s approximate 2,500 international clients are companies from the plastics and fiber industries, as well as from the chemicals and automobile sectors. For every cleaning need, the company with its approximately 80 employees offers the most economically, ecologically and qualitatively best technology and cleaning solution. SCHWING is also a reliable service partner for contract cleaning by processing more than 250,000 tools and parts each year to the highest environmental and qualitative standards. So far, there has not been a single component that we have not been able to free from polymers and inorganic contaminants, confirm the three managing directors Ewald Schwing, Thomas Schwing and Alfred Schillert. Founded in 1969, the company celebrates its 50th anniversary in 2019 and opened SCHWING Technologies North America Inc., a new sales company in the USA, this year.

Press contact:

Nicola Leffelsend

SCHWING Technologies GmbH

Oderstraße 7

47506 Neukirchen-Vluyn

Germany

T +49 2845 930 146

redaktion@schwing-tech.com

www.schwing-technologies.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Compounding World Expo 2019: SCHWING Technologies presents its thermal cleaning systems for machine parts and tooling here

News-ID: 1717968 • Views: …

More Releases from SCHWING Technologies GmbH

New at the trade fair K 2019: SCHWING Technologies cleans tall filter candles up …

Neukirchen-Vluyn (Germany), October 8, 2019. At this year's K 2019 in Düsseldorf from October 16 to 23, SCHWING Technologies will be presenting its extended vacuum pyrolysis system VACUCLEAN 0917 for the first time (Hall 9/booth A77). With this system, the German expert for environmentally friendly and energy-efficient thermal cleaning systems is primarily targeting users of especially tall filter candles and bundles up to 170 cm high and 0.90 cm in…

SCHWING Technologies: thermal cleaning of filter bundles for the packaging indus …

Neukirchen-Vluyn (Germany), September 4, 2019. The cleanliness of filter bundles and filter candles is essential when it comes to quality of the film. The packaging industry used to replace these filters, but today, they are often cleaned for reuse. Why? Depending on the degree of filtration, investments of roughly 600 Euro per filter candle are not uncommon. Cleaning in a VACUCLEAN vacuum pyrolysis system and other post-treatment equipment for reuse,…

ITMA 2019: Predictive maintenance secures production processes in the fiber indu …

Neukirchen-Vluyn (Germany), May 2, 2019. The production of textiles and clothing will be the focus of this year's ITMA 2019 in Barcelona. From June 20 to 26, 2019, the German specialist SCHWING Technologies will be presenting thermal cleaning solutions for polymer-contaminated production tools. In hall 7 / booth C120, SCHWING experts, Managing Director Thomas Schwing and Head of Sales Virgilio Perez Guembe, will inform about the potentials and advantages of…

More Releases for Thermal

Thermal Weeder Market

Thermal Weeder Market Value is Anticipated to Increase at a Stable CAGR over the Forecast Period (2023 to 2029). It provides an in-depth analysis of the market segments which include products, applications, and competitor analysis.

Important changes in the business allow key players to attain larger profits. This Thermal WeederMarket study report is the best way to make changes with the help of entire market condition and metrics provided here. These…

Rising Demand for Thermal Analysis Techniques to Boost Differential thermal anal …

[San Francisco, USA] - Market research firm Trouve360Reports has added a latest report on the global differential thermal analysis market. The report offers a comprehensive analysis of the market, providing insights into key trends, growth drivers, and challenges that are shaping the industry.

The report presents a detailed market introduction, highlighting the definition of differential thermal analysis and its applications in various industries. The market overview section of the report offers…

Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Market …

According to Market Study Report, Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Market provides a comprehensive analysis of the Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Market segments, including their dynamics, size, growth, regulatory requirements, competitive landscape, and emerging opportunities of global industry. An exclusive data offered in this report is collected by research and industry experts team.

Get Free Sample PDF (including full TOC,…

What is the Difference Between Direct Thermal and Thermal Transfer Labels?

Northern Label Systems, specialists in supplying high quality labels explain the differences between Direct Thermal https://www.northern-label-systems.co.uk/labels-by-type/direct-thermal-labels and Thermal Transfer Labels https://www.northern-label-systems.co.uk/labels-by-type/thermal-transfer-labels

Thermal Transfer printing uses an ink ribbon to transfer the printed image from the heated printhead of the label printer onto the surface of the label while Direct Thermal printing transfers the image directly onto a heat sensitive material.

There are advantages and disadvantages to both methods. Direct Thermal label…

Global Thermal Transfer Material Market, Global Thermal Transfer Material Indust …

Thermal conductivity refers as an important characteristic for several manufacturing operations. Thermal transfer properties of a variety of materials are effective in certain applications owing to natural molecular structure that allows for direct heat-transfer. Thermal transfer materials are extensively used to manufacture the heat conductive adhesive tapes, printable products and polymer sheets. These polymer sheets are utilized for barcodes, labeling, and QR code labels for retailing, logistics, and consumer goods.…

Global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) …

Qyresearchreports include new market research report "Global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) Sales Market Report 2018" to its huge collection of research reports.

This report studies the global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) market status and forecast, categorizes the global Thermal Carbon Black Products (Low Thermal, Medium Thermal, High Thermal) market size (value & volume) by key players, type, application, and…