Press release

SCHWING Technologies: Partial heat treatment of rolls, extruder screws and broaching tools

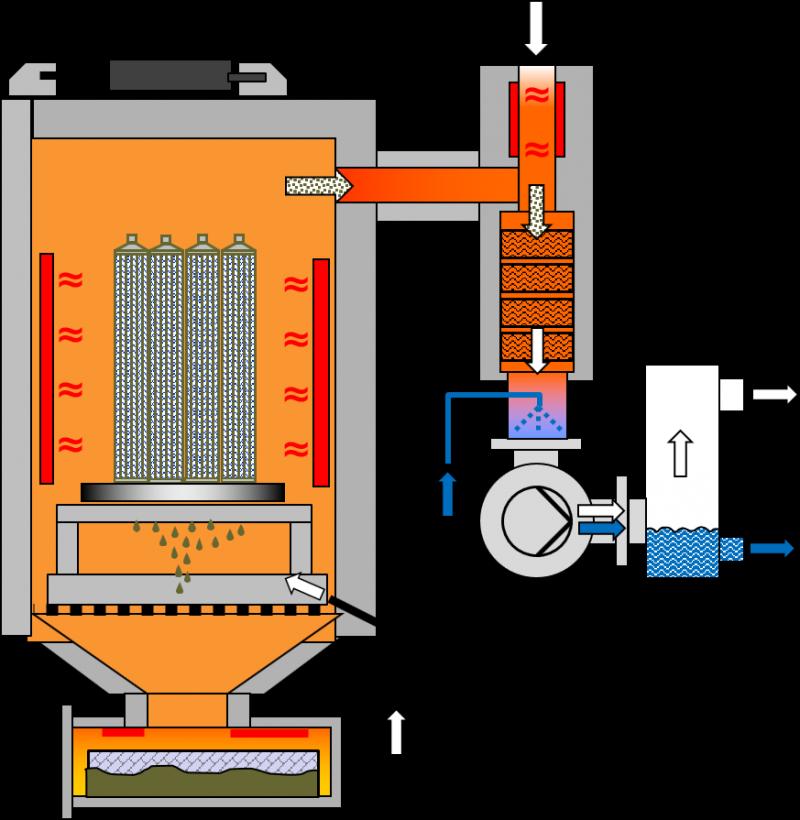

Roll immediately after partial tempering: Heat treatment in a SCHWING fluidized bed at SSC Werkstofftechnik GmbH

Partial heat treatment of rolls

SSC Werkstofftechnik GmbH, based in Lüdenscheid, benefits from this. The company has been working with fluidized bed systems from SCHWING for several years. Dirk Pritschke is Managing Director of SSC and particularly appreciates the fact that he can partially temper his customers' rolls at the desired temperature within a very short time. "It is important for us that the quality is right and that we as a service provider can work quickly and precisely and react flexibly," emphasizes Pritschke. "This is why we are convinced by SCHWING's fluidized bed technology". The systems are indirectly heated by electric heaters and can be used over a wide temperature range, from room temperature to 1050 degrees Celsius. Fine-grained aluminum oxide is fluidized with compressed air or other gas in a process chamber resulting in a fluidized bed that is not only highly thermally conductive, but also has a special heat capacity due to its mass. "The rolls can easily be immersed in the fluidized bed. We can then treat them very precisely at the desired temperature. The process can be carried out quickly and the results can be reproduced at any time," says Pritschke. Further advantages are the energy efficiency and environmental friendliness of the space-saving systems. In addition, they are safer than salt baths and do not pose any health risks.

Further information on heat treatment in a fluidized bed from SCHWING: https://www.heat--treatment.com/de.html

SCHWING Technologies

SCHWING Technologies GmbH has been on the market for 50 years and is the global technology leader for high-temperature systems for thermal cleaning, thermo-chemical material finishing and heat treatment of metal parts and tools in the manufacturing industry. The owner-managed company designs, manufactures and operates its systems at its headquarters in Neukirchen-Vluyn on the Lower Rhine. Its Managing directors are company founder Ewald Schwing, his son Thomas Schwing and Alfred Schillert. Founded in 1969, the company celebrates its 50th anniversary in 2019, and opened a new sales company in the USA this year: SCHWING Technologies North America Inc.

Press contact

Nicola Leffelsend

SCHWING Technologies GmbH

Oderstraße 7

47506 Neukirchen-Vluyn

T +49 2845 930 146

redaktion@schwing-tech.com

www.schwing-technologies.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release SCHWING Technologies: Partial heat treatment of rolls, extruder screws and broaching tools here

News-ID: 1699125 • Views: …

More Releases from SCHWING Technologies GmbH

New at the trade fair K 2019: SCHWING Technologies cleans tall filter candles up …

Neukirchen-Vluyn (Germany), October 8, 2019. At this year's K 2019 in Düsseldorf from October 16 to 23, SCHWING Technologies will be presenting its extended vacuum pyrolysis system VACUCLEAN 0917 for the first time (Hall 9/booth A77). With this system, the German expert for environmentally friendly and energy-efficient thermal cleaning systems is primarily targeting users of especially tall filter candles and bundles up to 170 cm high and 0.90 cm in…

SCHWING Technologies: thermal cleaning of filter bundles for the packaging indus …

Neukirchen-Vluyn (Germany), September 4, 2019. The cleanliness of filter bundles and filter candles is essential when it comes to quality of the film. The packaging industry used to replace these filters, but today, they are often cleaned for reuse. Why? Depending on the degree of filtration, investments of roughly 600 Euro per filter candle are not uncommon. Cleaning in a VACUCLEAN vacuum pyrolysis system and other post-treatment equipment for reuse,…

ITMA 2019: Predictive maintenance secures production processes in the fiber indu …

Neukirchen-Vluyn (Germany), May 2, 2019. The production of textiles and clothing will be the focus of this year's ITMA 2019 in Barcelona. From June 20 to 26, 2019, the German specialist SCHWING Technologies will be presenting thermal cleaning solutions for polymer-contaminated production tools. In hall 7 / booth C120, SCHWING experts, Managing Director Thomas Schwing and Head of Sales Virgilio Perez Guembe, will inform about the potentials and advantages of…

More Releases for Roll

How Roll to Roll Printing Is Transforming High Speed Manufacturing

The roll-to-roll printing market has emerged as a cornerstone of modern manufacturing, enabling high-speed, continuous production of electronic, optical, and functional components on flexible substrates. This technology involves processing flexible materials such as plastic films, foils, and papers through a rolling mechanism, allowing printing, coating, or patterning at scale. Its ability to deliver precision, consistency, and cost efficiency makes it indispensable across industries ranging from consumer electronics to healthcare and…

Mobi-Roll expands mobility solutions: The new Mobi-Roll Walker

Moers, 8.12.2024- The Mobi-Roll brand is expanding its product portfolio with an innovative solution for people with limited mobility. The Mobi-Roll MRW 23 and MRW 24 models fill a gap in the market: a four-wheeled walker that has been specially developed for users who can actively use their legs to get around but are not allowed to put any strain on their legs.

Unique and functional

The Mobi-Roll walkers MRW 23 and…

Roll-to-Roll Printing Market Analysis On Trends & Need 2025

Global Roll-to-Roll Printing Market: Snapshot

Roll-to-roll (R2R) printing refers to a family of manufacturing technologies that involves the constant processing of a flexible substrate as it is moved between two moving rolls of material. Advancements in the field of R2R have made it an important class of substrate-based manufacturing process in which subtractive and additive techniques are used to build structures in a constant manner. The process, comprises many techniques that,…

Roll to Roll Printers Market Size, Share, Development by 2025

LP INFORMATION recently released a research report on the Roll to Roll Printers analysis, which studies the Roll to Roll Printers industry coverage, current market competitive status, and market outlook and forecast by 2025.

Global “Roll to Roll Printers Market 2020-2025” Research Report categorizes the global Roll to Roll Printers by key players, product type, applications and regions,etc. The report also covers the latest industry data,…

Global Roll to Roll Printers Market Analysis by 2020-2025

Global Info Research offers a latest published report on Roll to Roll Printers Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. This report focuses on the key global Roll to Roll Printers Concentrate players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

Click to view the full report…

Roll-to-Roll Printing Market : Comprehensive Analysis and Future Estimations 202 …

Global Roll-to-Roll Printing Market: Snapshot

Roll-to-roll (R2R) printing refers to a family of manufacturing technologies that involves the constant processing of a flexible substrate as it is moved between two moving rolls of material. Advancements in the field of R2R have made it an important class of substrate-based manufacturing process in which subtractive and additive techniques are used to build structures in a constant manner. The process, comprises many techniques that,…