Press release

Electrostatic Chucks for Wafer Market Share of Top 3 and Top 5 Manufacturers (SHINKO, TOTO, Creative Technology Corporation)

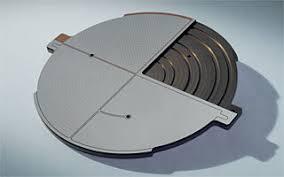

A chuck is a specialized type of clamp used to hold an object with radial symmetry, especially a cylinder. In drills and mills it holds the rotating tool whereas in lathes it holds the rotating workpiece. On a lathe the chuck is mounted on the spindle which rotates within the headstock. For some purposes (such as drilling) an additional chuck may be mounted on the non-rotating tailstock.In this report, the Global Electrostatic Chucks for Wafer Market is valued at USD XX million in 2018 and is expected to reach USD XX million by the end of 2025, growing at a CAGR of XX% between 2018 and 2025.

Request Sample Copy of Electrostatic Chucks for Wafer Market Report:

https://www.marketreportsworld.com/enquiry/request-sample/11374285

Many chucks have jaws, (sometimes called dogs) that are arranged in a radially symmetrical pattern like the points of a star. The jaws are tightened up to hold the tool or workpiece. Often the jaws will be tightened or loosened with the help of a chuck key, which is a wrench-like tool made for the purpose Many jawed chucks, however, are of the keyless variety, and their tightening and loosening is by hand force alone. Keyless designs offer the convenience of quicker and easier chucking and unchucking, but have lower gripping force to hold the tool or workpiece, which is potentially more of a problem with cylindrical than hexagonal shanks. Collet chucks, rather than having jaws, have collets, which are flexible collars or sleeves that fit closely around the tool or workpiece and grip it when squeezed.

Methods of Electrostatic Chucks for Wafer Market:

Mounting of drill chucks

A threaded arbour may screw into the chuck body.

A tapered arbour (with a self-holding taper) may be pressed into the chuck body.

Removal and insertion may involve various tools or methods:

Tools: vies (especially with a wooden jig or soft jaw made for this purpose); hammer (especially nonmarring hammer or rubber mallet); arbor press or shop press (the latter two require skill to avoid damaging the chuck).

Methods: heating (via heat guns, blow torches, or ovens) and cooling (via kitchen freezers, winter weather, or decompression of compressed air or nitrogen).

A drill chuck may have a hollow body that threads directly onto a lathe's threaded spindle nose. (These are fairly rare, especially nowadays.)

Mounting of large jawed chucks

Taper spindle nose with threaded retention. The retainer ring is wrenched with a spanner wrench.A backplate with threads may screw onto a threaded spindle nose (for lathe work) or onto an adapter plate with the same nose, to be mounted on the table of milling machines or surface grinding machines. This "threaded spindle nose" type of mounting was the typical method in the 19th century through 1930s. It is simple and useful, but the degree of control of concentricity is not quite good enough to be foolproof for high-speed, high-precision work (high precision can be achieved, but the time and skill involved in the setups makes it a poor choice now that better options exist, such as the cam-lock spindle noses described below). Threaded spindle noses are still built on new machine tools, but only of the low-end variety (hobbyist, least-expense MRO, etc.). High-capital manufacturing (where high upfront expense yields lowest possible unit expense for mid- to high-volume part counts of high-precision parts) has moved away from this type of mounting. The exact-adjust (Set-Tru) concept is one way to chase high concentricity on threaded spindle noses with some relative degree of ease.

A common solution on smaller lathes is a broad flanged end to the spindle with a concentric raised circular register matching a recess in the chuck or its backplate. The register is normally shallow and parallel sided and a light push fit in the female register of the chuck. The chuck is held in place with bolts through clearance holes that do not affect the alignment which is entirely provided by the register. This arrangement has excellent repeatability but is slow in a production situation.

A backplate with a female (self-releasing) taper may seat on the matching male taper of the taper(ed) spindle nose (for lathe work) or of an adapter plate with the same nose, to be mounted on a table. This system improves the repeatability of the mounting concentricity down to a very small total indicated runout (TIR) value. Subtypes:

The chuck may be held against the taper with a threaded retainer ring (large thin nut), typically wrenched with a spanner wrench of the pin or hook variety. The peak of popularity for building this type of spindle nose was the 1940s and 1950s.

The chuck may be held against the taper with cam-lock posts that wedge into a stuck-fast position. Industry-standard spindle nose designs allow wide interchangeability. This cam lock spindle nose system replaced the earlier systems on most machine tools in the 1960s.

Place a Purchase Order For Electrostatic Chucks for Wafer Market At: https://www.marketreportsworld.com/purchase/11374285

Mounting of collet chucks

For collet chucks mounted on backplates, all of the same methods above are applicable.

Many lathes that run collet chucks have dedicated collet-closer setups whereby there is no backplate, and the spindle nose contains the female taper for either the collet's male outer taper, or a sleeve that will hold it. A hollow drawbar passes back through the headstock to its back side, where a closer mechanism is mounted. The latter allows easy, rapid opening and closing of the collet. The drawbar's inner diameter determines the through-the-spindle bar diameter capacity of the lathe. Some collet-closer systems even allow opening and closing without stopping the spindle rotation. The closer on a manual lathe is either lever-style or handwheel-style. The closer on a CNC lathe is powered (electric, hydraulic, or pneumatic), and it may be controlled by various means: a foot pedal that the operator steps on when desired; a line in the program (for opening and closing under program control); or a button on the control panel.

National and international standards are used to standardize the definitions, requirements, and test methods used for the performance evaluation of chucks. Selection of the standard to be used is an agreement between the supplier and the user and has some significance in the design of the chuck. In the United States, ASME has developed the B5.60 Standard entitled Workholding Chucks: Jaw-Type Chucks, which establishes requirements and methods for specifying and testing the performance of Workholding chucks used primarily in turning operation

Contact Us:

Mr.Ajay More

Phone : +1 408 520 9750

Email : sales@marketreportsworld.com

ABOUT Us:

Market is changing rapidly with the ongoing expansion of the industry. Advancement in the technology has provided today’s businesses with multifaceted advantages resulting in daily economic shifts. Thus, it is very important for a company to comprehend the patterns of the market movements in order to strategize better. An efficient strategy offers the companies with a head start in planning and an edge over the competitors. Market Reports World is the credible source for gaining the market reports that will provide you with the lead your business needs.

Market Reports World

3rd Floor, Silver Spring, Sahyadri farms,

Opp Prabhavee Tech Park,

Baner - Mhalunge Road, Baner, Pune 411045.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Electrostatic Chucks for Wafer Market Share of Top 3 and Top 5 Manufacturers (SHINKO, TOTO, Creative Technology Corporation) here

News-ID: 1435672 • Views: …

More Releases from marketreportsworld

Modular Data Centers Market Size, Share 2020 Size, Share Analysis by Manufacture …

Modular Data Centers market analysis report speaks about the manufacturing process. The process is analysed thoroughly with four points Manufacturers, regional analysis, Segment by Type & Applications and the actual process of whole Modular Data Centers industry.

A complete analysis of the competitive landscape of the Modular Data Centers Market is provided in the report. This section includes company profiles of market key players. The profiles include contact information, gross, capacity,…

Blockchain Technology in Financial Market Revenue Emerging Key Players Supply De …

Blockchain Technology in Financial market analysis report speaks about the manufacturing process. The process is analysed thoroughly with four points Manufacturers, regional analysis, Segment by Type & Applications and the actual process of whole Blockchain Technology in Financial industry.

A complete analysis of the competitive landscape of the Blockchain Technology in Financial Market is provided in the report. This section includes company profiles of market key players. The profiles include contact…

Low Smoke Halogen Free Cable Market 2020: Emerging Technologies, Sales Revenue, …

Low Smoke Halogen Free Cable market analysis report speaks about the manufacturing process. The process is analysed thoroughly with four points Manufacturers, regional analysis, Segment by Type & Applications and the actual process of whole Low Smoke Halogen Free Cable industry.

A complete analysis of the competitive landscape of the Low Smoke Halogen Free Cable Market is provided in the report. This section includes company profiles of market key players. The…

Broadband Satellite Services Market Size, Share 2020 Analysis, Latest Trends and …

Broadband Satellite Services market analysis report speaks about the manufacturing process. The process is analysed thoroughly with four points Manufacturers, regional analysis, Segment by Type & Applications and the actual process of whole Broadband Satellite Services industry.

A complete analysis of the competitive landscape of the Broadband Satellite Services Market is provided in the report. This section includes company profiles of market key players. The profiles include contact information, gross, capacity,…

More Releases for Chucks

Electrostatic Chucks Market Revenue Share, Insights & Future Outlook

Electrostatic Chucks Market Size

The global Electrostatic Chucks revenue was US$ 1793.6 million in 2022 and is forecast to a readjusted size of US$ 2543.6 million by 2029 with a CAGR of 5.2% during the forecast period (2023-2029).

Download Free Data: https://reports.valuates.com/request/sample/QYRE-Auto-25A15705/Global_and_India_Electrostatic_Chucks_Market_Report_Forecast_2023_2029?utm_source=Openpr&utm_medium=referral

Semiconductor Process market covers Coulomb Type, Johnsen-Rahbek (JR) Type. The typical players include Applied Materials, Lam Research, SHINKO, TOTO, Sumitomo Osaka Cement, Creative Technology Corporation, Kyocera, Entegris, etc.

In India, the Electrostatic…

Global Wafer Chucks Market Analysis by 2020-2025

Global Info Research offers a latest published report on Wafer Chucks Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. This report focuses on the key global Wafer Chucks Concentrate players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

Click to view the full report TOC, figure and tables:

https://www.globalinforesearch.com/Global-Wafer-Chucks_p507243.html

Market…

Turning Chucks Market Size, Share, Development by 2024

Global Info Research offers a latest published report on Turning Chucks Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. This report focuses on the key global Turning Chucks players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Turning Chucks with respect to individual growth…

Global Electrostatic Chucks for Wafer Market Insights, Forecast

This report presents the worldwide Electrostatic Chucks for Wafer market size (value, production and consumption), splits the breakdown (data status 2013-2018 and forecast to 2025), by manufacturers, region, type and application. This study also analyzes the market status, market share, growth rate, future trends, market drivers, opportunities and challenges, risks and entry barriers, sales channels, distributors and Porter's Five Forces Analysis

Get sample copy of the report:

https://www.marketdensity.com/contact?ref=Sample&reportid=50281

Table of Contents:

Table of Contents

1…

Drill Chucks Market Overview by 2025: QY Research

Drill Chucks Market status and forecast, categorizes the global market size (value & volume) by key players, type, application, and region.

Los Angeles, United State, Feb 2, 2019 (satPRnews) – The Report provide in-depth analysis and the best research material of the various market. This new report on the Global Drill Chucks Market is committed fulfilling the requirements of the clients by giving them thorough insights into the market. An exclusive data offered in…

Vacuum Chucks Market Overview by 2025: QY Research

This recently published report examines the global Vacuum Chucks market for the projected period of 7-years, i.e. between 2018 and 2025. The report highlights the accomplishments and opportunities lies in the market throughout the forecasted period. The report offers the thorough information about the overview and the scope of the global Vacuum Chucks market along with its drivers, restraints, and trends. It also classifies the market into different segments such…