Press release

Additive Manufacturing with Metal Powders Market to surpass $1.1 bn by 2024| 3D Systems, Trumpf, Renishaw, EOS, Arcam, GE, Concept Laser, Realizer, Optomec

Global Market Insights presents a most up-to-date research on “Additive manufacturing with metal powders market – Global Industry Analysis, Size, Share, By Application (Aerospace, Automotive, Medical, Oil & Gas) Growth Potential, Trends Statistics, Regional Outlook (U.S., Canada, Germany, UK, France, Italy, Spain, Russia, Poland, China, Japan, India, South Korea, Australia, Taiwan, Brazil, Mexico, Argentina, Saudi Arabia, UAE, South Africa) and Forecast 2017 – 2024”.Positive application scope in aerospace industry in making engine, turbine parts and interiors should trigger additive manufacturing with metal powders market growth. Over 20% of aerospace engineering companies are using this technology to make tooling components. The industry is constantly putting effort to minimize aircraft weight by using lightweight metals such as stainless steel, titanium, aluminum, and copper.

Request for a sample copy of this report @

https://www.gminsights.com/request-sample/detail/1783

Additive manufacturing with metal powders market size from oil & gas application is likely to be valued at over USD 45 million over the projected timespan. Prototyping and modelling for exploration and operational equipment, chemical injection stick tools, gears, impellers, pipeline rigs, nozzles for downhole cleanout tools, control valve components, large scale downhole tools and sealing accessories including O rings are produced through 3D printing which are used in the industry.

Increased usage of these technologies in making complex components for oil & gas industries, while cutting costs, reducing emissions and boosting performance, should trigger additive manufacturing with metal powders demand.

Growing trust for these technologies in aerospace firms, should minimize costs for developing models and prototypes, resulting in additive manufacturing with metal powders market growth.

Additive Manufacturing with Metal Powders Market size is expected to cross USD 1.1 billion by 2024; according to a new research report by Global Market Insights, Inc.

Browse Complete Summary of this report @

https://www.gminsights.com/industry-analysis/additive-manufacturing-with-metal-powders-market

Increase in trend towards adoption of prototype has led to the development and validation of design faster along with reduction in production time & cost in various industrial sectors which has stimulated additive manufacturing with metal powders market demand. Increasing E&P activities in oil & gas sector has forced manufacturers for various technological advancements in 3D printing for efficient oil recovery, thereby propagating metal additive manufacturing market growth.

U.S. additive manufacturing with metal powders market size may exceed USD 400 million during the forecast timeframe. Growing health concerns, ageing population and long track of chronic disease coupled with strong regulatory regimes regarding medical device industry should propel regional demand. Improvement in long-term patient outcomes for surgeries and treatment along with growing oral rehabilitation demand should surge technology growth in the region.

Make an inquiry for purchasing this report @

https://www.gminsights.com/inquiry-before-buying/1783

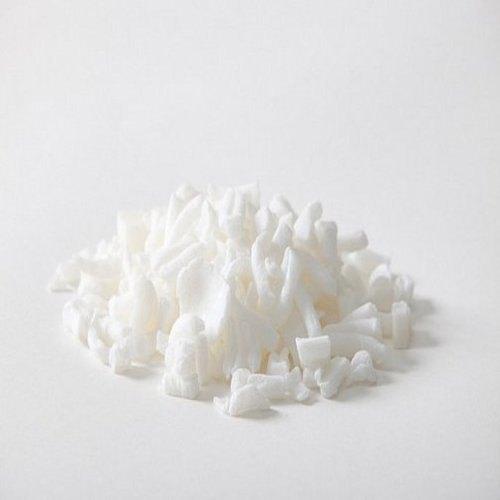

Stainless steel, aluminum, cobalt, nickel and titanium powders are the prominent raw materials used in the additive manufacturing with metal powders method. Infringement law issues regarding the product and the technology along with volatility in regional raw material prices may impact demand supply gap and hinder industry profitability.

Report Content:

Chapter 2 Executive Summary

2.1 Additive manufacturing with metal powders industry 3600 synopsis, 2013 - 2024

2.1.1 Business trends

2.1.2 Regional trends

2.1.3 Manufacturing technique trends

2.1.4 Material trends

2.1.5 Application trends

Chapter 3 Additive Manufacturing with Metal Powders Industry Insights

3.1 Industry segmentation

3.2 Industry landscape, 2013-2024

3.3 Industry ecosystem analysis

3.3.1 Vendor matrix

3.3.2 Distribution channel analysis

3.3.2.1 Collaboration/partnerships

3.3.2.2 Distributors

3.3.2.3 Service providers

3.3.2.4 Technology providers

3.3.3 Profit margin analysis

3.4 Pricing analysis

3.4.1 Regional pricing analysis

3.4.2 Cost structure analysis

3.5 Technology landscape

3.5.1 Powder bed fusion

3.5.2 Blown powder

3.5.3 Binder jetting

3.6 Technology comparison

3.7 Powder Characteristics

3.8 Regulatory landscape

3.8.1 ASTM International

3.8.1.1 ISO / ASTM52910 – 17: Standard Guidelines for Design for Additive Manufacturing

3.8.1.2 ASTM F2924 - 14: Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4 Vanadium with Powder Bed Fusion

3.8.1.3 ASTM F3001 - 14: Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4 Vanadium ELI (Extra Low Interstitial) with Powder Bed Fusion

3.8.1.4 ASTM F3049 - 14: Standard Guide for Characterizing Properties of Metal Powders Used for Additive Manufacturing Processes

3.8.1.5 ASTM F3187 - 16: Standard Guide for Directed Energy Deposition of Metals

3.8.2 Europe Union Horizon 2020 Programme (H2020)

3.8.3 ISO Standards

3.8.3.1 ISO 17296-4:2014

3.8.3.2 ISO/ASTM 52901:2017

3.8.4 China

3.8.4.1 China Food and Drug Administration (CFDA)

3.8.4.1.1 Introduction

3.8.4.1.2 Application

3.8.4.1.3 Product testing

3.8.4.1.4 Evaluation

3.9 Industry impact forces

3.9.1 Growth drivers

3.9.1.1 North America: Technological advancements in medicine industry

3.9.1.2 Europe: Enhanced application scope in automotive and aerospace sector

3.9.1.3 Asia Pacific: Government initiatives to enhance additive manufacturing technology

3.9.1.4 MEA: Replacement of conventional technology in oil & gas exploration and production activities

3.9.2 Industry pitfalls & challenges

3.9.2.1 Technological limitation

3.9.2.2 Intellectual property issues

3.10 Innovation & sustainability

3.11 Growth potential analysis, 2016

3.11.1 Emerging business model

3.11.1.1 Collaboration/Joint ventures

3.11.1.2 Acquisitions

3.11.1.3 New product launch

3.11.1.4 Contract manufacturing

3.12 Porter’s analysis

3.13 Competitive landscape, 2016

3.13.1 Company market share analysis, 2016

3.13.2 Strategy dashboard

3.14 PESTEL analysis

Chapter 4 Additive Manufacturing with Metal Powders Market, By Manufacturing Technique

4.1 Additive manufacturing with metal powders manufacturing technique market share, 2016 & 2024

4.2 Powder Bed

4.2.3 Direct Metal Laser Sintering (DMLS)

4.2.4 Selective Laser Melting (SLM)

4.2.5 Electron Beam Melting (EBM)

4.3 Blown powder

4.3.3 Direct Metal Deposition (DMD)

4.3.4 Laser Engineering Net Shape (LENS)

Global Market Insights presents a most up-to-date research on “Additive manufacturing with metal powders market – Global Industry Analysis, Size, Share, By Application (Aerospace, Automotive, Medical, Oil & Gas) Growth Potential, Trends Statistics, Regional Outlook (U.S., Canada, Germany, UK, France, Italy, Spain, Russia, Poland, China, Japan, India, South Korea, Australia, Taiwan, Brazil, Mexico, Argentina, Saudi Arabia, UAE, South Africa) and Forecast 2017 – 2024”.

Positive application scope in aerospace industry in making engine, turbine parts and interiors should trigger additive manufacturing with metal powders market growth. Over 20% of aerospace engineering companies are using this technology to make tooling components. The industry is constantly putting effort to minimize aircraft weight by using lightweight metals such as stainless steel, titanium, aluminum, and copper.

Request for a sample copy of this report @

https://www.gminsights.com/request-sample/detail/1783

Additive manufacturing with metal powders market size from oil & gas application is likely to be valued at over USD 45 million over the projected timespan. Prototyping and modelling for exploration and operational equipment, chemical injection stick tools, gears, impellers, pipeline rigs, nozzles for downhole cleanout tools, control valve components, large scale downhole tools and sealing accessories including O rings are produced through 3D printing which are used in the industry.

Increased usage of these technologies in making complex components for oil & gas industries, while cutting costs, reducing emissions and boosting performance, should trigger additive manufacturing with metal powders demand.

Growing trust for these technologies in aerospace firms, should minimize costs for developing models and prototypes, resulting in additive manufacturing with metal powders market growth.

Additive Manufacturing with Metal Powders Market size is expected to cross USD 1.1 billion by 2024; according to a new research report by Global Market Insights, Inc.

Browse Complete Summary of this report @

https://www.gminsights.com/industry-analysis/additive-manufacturing-with-metal-powders-market

Increase in trend towards adoption of prototype has led to the development and validation of design faster along with reduction in production time & cost in various industrial sectors which has stimulated additive manufacturing with metal powders market demand. Increasing E&P activities in oil & gas sector has forced manufacturers for various technological advancements in 3D printing for efficient oil recovery, thereby propagating metal additive manufacturing market growth.

U.S. additive manufacturing with metal powders market size may exceed USD 400 million during the forecast timeframe. Growing health concerns, ageing population and long track of chronic disease coupled with strong regulatory regimes regarding medical device industry should propel regional demand. Improvement in long-term patient outcomes for surgeries and treatment along with growing oral rehabilitation demand should surge technology growth in the region.

Make an inquiry for purchasing this report @

https://www.gminsights.com/inquiry-before-buying/1783

Stainless steel, aluminum, cobalt, nickel and titanium powders are the prominent raw materials used in the additive manufacturing with metal powders method. Infringement law issues regarding the product and the technology along with volatility in regional raw material prices may impact demand supply gap and hinder industry profitability.

Report Content:

Chapter 2 Executive Summary

2.1 Additive manufacturing with metal powders industry 3600 synopsis, 2013 - 2024

2.1.1 Business trends

2.1.2 Regional trends

2.1.3 Manufacturing technique trends

2.1.4 Material trends

2.1.5 Application trends

Chapter 3 Additive Manufacturing with Metal Powders Industry Insights

3.1 Industry segmentation

3.2 Industry landscape, 2013-2024

3.3 Industry ecosystem analysis

3.3.1 Vendor matrix

3.3.2 Distribution channel analysis

3.3.2.1 Collaboration/partnerships

3.3.2.2 Distributors

3.3.2.3 Service providers

3.3.2.4 Technology providers

3.3.3 Profit margin analysis

3.4 Pricing analysis

3.4.1 Regional pricing analysis

3.4.2 Cost structure analysis

3.5 Technology landscape

3.5.1 Powder bed fusion

3.5.2 Blown powder

3.5.3 Binder jetting

3.6 Technology comparison

3.7 Powder Characteristics

3.8 Regulatory landscape

3.8.1 ASTM International

3.8.1.1 ISO / ASTM52910 – 17: Standard Guidelines for Design for Additive Manufacturing

3.8.1.2 ASTM F2924 - 14: Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4 Vanadium with Powder Bed Fusion

3.8.1.3 ASTM F3001 - 14: Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4 Vanadium ELI (Extra Low Interstitial) with Powder Bed Fusion

3.8.1.4 ASTM F3049 - 14: Standard Guide for Characterizing Properties of Metal Powders Used for Additive Manufacturing Processes

3.8.1.5 ASTM F3187 - 16: Standard Guide for Directed Energy Deposition of Metals

3.8.2 Europe Union Horizon 2020 Programme (H2020)

3.8.3 ISO Standards

3.8.3.1 ISO 17296-4:2014

3.8.3.2 ISO/ASTM 52901:2017

3.8.4 China

3.8.4.1 China Food and Drug Administration (CFDA)

3.8.4.1.1 Introduction

3.8.4.1.2 Application

3.8.4.1.3 Product testing

3.8.4.1.4 Evaluation

3.9 Industry impact forces

3.9.1 Growth drivers

3.9.1.1 North America: Technological advancements in medicine industry

3.9.1.2 Europe: Enhanced application scope in automotive and aerospace sector

3.9.1.3 Asia Pacific: Government initiatives to enhance additive manufacturing technology

3.9.1.4 MEA: Replacement of conventional technology in oil & gas exploration and production activities

3.9.2 Industry pitfalls & challenges

3.9.2.1 Technological limitation

3.9.2.2 Intellectual property issues

3.10 Innovation & sustainability

3.11 Growth potential analysis, 2016

3.11.1 Emerging business model

3.11.1.1 Collaboration/Joint ventures

3.11.1.2 Acquisitions

3.11.1.3 New product launch

3.11.1.4 Contract manufacturing

3.12 Porter’s analysis

3.13 Competitive landscape, 2016

3.13.1 Company market share analysis, 2016

3.13.2 Strategy dashboard

3.14 PESTEL analysis

Chapter 4 Additive Manufacturing with Metal Powders Market, By Manufacturing Technique

4.1 Additive manufacturing with metal powders manufacturing technique market share, 2016 & 2024

4.2 Powder Bed

4.2.3 Direct Metal Laser Sintering (DMLS)

4.2.4 Selective Laser Melting (SLM)

4.2.5 Electron Beam Melting (EBM)

4.3 Blown powder

4.3.3 Direct Metal Deposition (DMD)

4.3.4 Laser Engineering Net Shape (LENS)

Contact Us

Arun Hegde

Corporate Sales, USA

Global Market Insights, Inc.

Phone: 1-302-846-7766

Toll Free: 1 888-689-0688

Email: sales@gminsights.com

Web: https://www.gminsights.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Additive Manufacturing with Metal Powders Market to surpass $1.1 bn by 2024| 3D Systems, Trumpf, Renishaw, EOS, Arcam, GE, Concept Laser, Realizer, Optomec here

News-ID: 1311784 • Views: …

More Releases from Global Market Insights Inc.

Latest Research Report On Agricultural Adjuvants Market 2021. Major Players Incl …

The agricultural adjuvants market is expected to observe noteworthy growth on account of increasing demand for high-quality crops. Adjuvants commonly act as an additive in pesticides that increase its effectiveness and smoothen its mixing application.

The demand for plant protection products in countries like Bangladesh, India, and Vietnam has surged considerably in recent years. Ever-increasing population across developing economies has forced farmers to produce large quantities of high-quality yields. Citing…

U.S. Minoxidil Market 2021 Growth Opportunities and Competitive Landscape 2027 - …

The U.S. minoxidil industry has been impacted by the COVID-19 pandemic in the form of increased stress amid job losses and health issues, creating rising incidences of hair fall and associated problems. The industry is expected to gain commendable proceeds on account of an upsurge in research studies concerned with the effectiveness of minoxidil.

Citing one such instance, in January 2021, a study published in the Dermatologic Therapy supported the efficacy…

Global Sulfosuccinate Market 2021 Future Growth With Technology and Current Tren …

Owing to these factors, estimates have revealed that the global sulfosuccinate market size will exceed USD 475.7 million in annual estimation by 2024.

Increasing adoption of high-performance materials that meet application-specific requirements across various industries, including pharmaceuticals will stimulate the need for sulfosuccinate compounds. The surging disposable incomes of consumers mainly across the developing nations have also fueled their spending capacities on household and personal care.

Sulfosuccinates are mainly a mild type…

By 2026, Graphene Market will register over 35% CAGR | Applied Nanotech, Inc, an …

The global Graphene Market is slated to gain significant momentum over the forthcoming years, as a result of the growing product consumption in the electronics sector, particularly in developing countries. This high consumption can be attributed to its superior qualities such as high electrical conductivity, durability, and toughness.

Request a sample of this research report @

https://www.gminsights.com/request-sample/detail/233

Top Key Players in The Market are:

Graphenea S.A., Applied Graphene Materials plc, ACS…

More Releases for Additive

Prominent Additive Manufacturing Market Trend for 2025: Development of Digital A …

Which drivers are expected to have the greatest impact on the over the additive manufacturing market's growth?

The additive manufacturing market is set to flourish due to the surging demands for 3D printing. This term refers to the process of making three-dimensional solid objects from electronic files. 3D printing brings cost-effectiveness and flexibility to additive manufacturing, specifically in manufacturing personalized components and planning before an operation. For example, AZoNetwork UK Ltd.,…

Metal Additive Manufacturing Systems Market to See Huge Growth by 2030 | Renisha …

Advance Market Analytics published a new research publication on "Metal Additive Manufacturing Systems Market Insights, to 2030" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Metal Additive Manufacturing Systems market was mainly driven by the increasing R&D spending across the world.

Get inside Scoop…

Additive Masterbatch Market Report 2024 - Additive Masterbatch Market Size, Shar …

"The Business Research Company recently released a comprehensive report on the Global Additive Masterbatch Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

Ready to Dive into Something Exciting? Get Your Free Exclusive Sample…

Medicated Bath Additive Market Report 2024 - Medicated Bath Additive Market Grow …

"The Business Research Company recently released a comprehensive report on the Global Medicated Bath Additive Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

According to The Business Research Company's, The medicated bath…

Laser Additive Manufacturing Market Is Booming Worldwide| GE Additive, Autodesk, …

Advance Market Analytics published a new research publication on "Laser Additive Manufacturing Market Insights, to 2028" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Laser Additive Manufacturing market was mainly driven by the increasing R&D spending across the world.

Get Free Exclusive PDF Sample…

Aquaculture Additive Market

The Insight Partners analysts forecasts the latest report on “Global Aquaculture Additive Market (Covid-19) Impact and Analysis by 2027”, according to report; The Aquaculture Additive Market report covers the overall and all-inclusive analysis of Market with all its factors that have an impact on market growth. This report is anchored on the thorough qualitative and quantitative assessment of the Aquaculture Additive Market.

The COVID-19 outbreak is currently going the world…