Press release

Silicone Additives Market Analysis 2018 – 2023, Global Size Estimation by DowDuPont , Evonik Industries AG, Shin-Etsu Chemical, Elkem, Momentive, KCC Corporation, Wacker Chemie AG, BYK Additives, Siltech Corporation, BRB International

Increasing use of Silicone Additives in various industries is set to fuel the product demand over the forecast period

Asia Pacific is the fastest growing silicone additives market in the globe due to growth of the construction industry along with wide availability of raw materials for Silicone Additives production. Increasing demand for packaged food and beverages as a result of hectic lifestyle along with significant increase in the number of working-class women is expected to augment market growth. Furthermore, growing aerospace and defense industry in India and China are fueling the demand for the Silicone Additives Market. The product used in the construction industry is increasing as a result of improving living standard coupled with rising purchasing power.

Get In-Depth Sample Report @ https://www.marketresearchfuture.com/sample_request/5800

North America is expected to grow at a staggering rate over the forecast period. Silicone Additives are being used increasingly in the automotive, marine and defense industries in this region. Moreover, Silicone Composites Ltd. introduced a new technique for ship manufacturing such as use of silicone vacuum bags.

Europe is witnessing a significant growth in the market as a result of growing flexible packaging market, especially in Italy, Poland, and Turkey. Furthermore, Europe based Constantia Flexibles has acquired India based Creative Polypack in 2017 to expand its base in the Indian subcontinent. Furthermore, the demand from automotive industry is growing due to emission targets set for the vehicle by the European Commission.

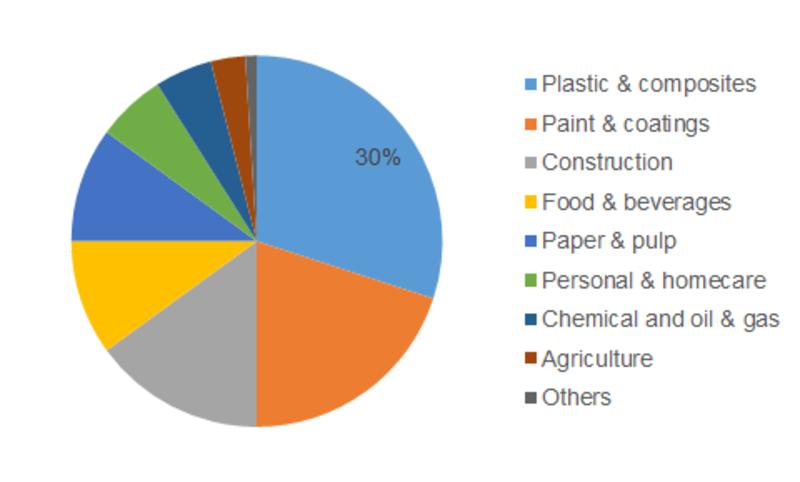

Silicone Additives are majorly used in plastics and composites for improving processing and surface properties of the plastic. These additives are used for improving the mold filling, surface lubricity, and wear resistance of plastic products. The product finds application in end-use industries including paints and coatings, paper and pulp, construction, personal care, and food & beverage. The second largest use of Silicone Additives is in paints and coatings industry to enhance the performance of the finished products and to reduce the surface tension of the liquid.

Thermoplastics manufacturers are increasingly using silicone additives due to its ideality in processing, modifying thermoplastics, and reducing the noise generated by the motion of plastic parts. For instance, new additive introduced by Wacker Chemie AG in 2016, one of the key players in the global silicone additives market, under the brand name GENIOPLAST, is widely used by the thermoplastic manufacturers. The product demand is increasing from the packaging industry because it enhances the lubricity and appearance of the product. Rising demand from automotive, renewable energy, and aerospace industries for materials and technically advanced equipment is driving the Silicone Additives Market.

Get In-Depth Sample Report @ https://www.marketresearchfuture.com/sample_request/5800

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by Components, Application, Logistics and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Contact:

Market Research Future

+1 646 845 9312

Email: sales@marketresearchfuture.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Silicone Additives Market Analysis 2018 – 2023, Global Size Estimation by DowDuPont , Evonik Industries AG, Shin-Etsu Chemical, Elkem, Momentive, KCC Corporation, Wacker Chemie AG, BYK Additives, Siltech Corporation, BRB International here

News-ID: 1267251 • Views: …

More Releases from Market Research Future

Subsea Manifolds Market Projection: USD 4,120.53 Million in 2025 Rising to USD 6 …

The subsea manifolds market plays a critical role in modern offshore oil and gas production by enabling efficient control, distribution, and monitoring of hydrocarbons on the seabed. Subsea manifolds act as gathering points that connect multiple wells to production systems, allowing operators to optimize flow management, reduce infrastructure complexity, and improve overall field performance. As offshore exploration moves into deeper waters and more technically challenging environments, subsea manifolds have become…

Military Cybersecurity Market 2026: Innovation, AI Defense, and Strategic Demand

In an era defined by rapidly evolving cyber threats and digital warfare, the Military Cybersecurity industry is undergoing a fundamental transformation. As nation-states, defense organizations, and allied forces expand their reliance on digital networks, unmanned systems, IoT-enabled platforms, and cloud infrastructures, securing military cyberspace has become a strategic priority. The shifting threat landscape is driving unprecedented demand for advanced cybersecurity solutions that can protect critical defense assets, ensure operational continuity,…

Drone Identification Market Thriving Worldwide industry with AI by 78.23 USD Bil …

The Drone Identification Market is gaining significant traction in 2026 as unmanned aerial systems (UAS) become more widespread across commercial, governmental, and recreational applications. With drone usage expanding rapidly, there is a pressing need for effective identification, tracking, and management systems that ensure airspace safety, regulatory compliance, and coordinated operations. This demand is driving investment in advanced technologies and solutions that support remote identification, situational awareness, and secure communications within…

Healthcare BPO Market to Reach USD 972.65 Billion by 2035, Expanding at 4.22% CA …

The Healthcare BPO (Business Process Outsourcing) Market is experiencing significant growth as healthcare providers increasingly outsource non-core functions to specialized service providers. Healthcare BPO services include medical billing and coding, claims processing, customer care, revenue cycle management, IT support, telehealth support, transcription services, and other administrative functions. Outsourcing enables healthcare organizations to reduce operational costs, improve process efficiency, and focus on core clinical services.

Market Overview and Growth Trends

As per Market…

More Releases for Silicone

Revolutionizing Industries: Tenchy Silicone Introduces Cutting-Edge Silicone Tub …

Shenzhen Tenchy Silicone And Rubber Co., Ltd, a renowned leader in silicone products manufacturing, proudly announces the launch of its advanced silicone tubing solutions. Designed to meet the diverse needs of industries such as medical, automotive, and food and beverage, these innovative products represent a significant step forward in silicone technology.

In a world where reliability, performance, and versatility are paramount, silicone tubing stands out as a material of choice for…

Five common properties of silicone and the primary Types of Silicone

Silicones are a versatile class of polymers that come in various forms, offering immense potential for customization to meet the precise needs of the medical and aerospace sectors. Their characteristics enable them to perform diverse functions, such as sealing, lubricating, and fulfilling a host of other tasks.

Silicone's versatility is attributed to its unique physical and mechanical properties, which make it a valuable material in various industries. This article will delve…

Tenchy Silicone: Quality Silicone Tube Supplier for Different Industries

Tenchy Silicone is proud to announce the opening of their new headquarters, which will provide a quality silicone tube supplier service to different industries and businesses. Their silicone tubes are made from FDA-approved materials and are temperature resistant up to 230 degrees Celsius. All products come with an assurance of quality from Tenchy Silicone's team of experienced engineers and technicians who ensure that each product meets customer needs and specifications.…

Tenchy Silicone introducing new silicone foam strip

Tenchy Silicone, the leading provider of high-quality silicone foam strip, is proud to announce their newest product. The Silicone Foam Strip features a combination of both closed-cell and open-cell foaming technologies which offers outstanding thermal insulation and water resistance properties as well as superior airtight performance. It also provides excellent cushioning for equipment, machinery, components and instruments to ensure protection from dust, moisture, abrasion and shock. In addition to its…

Tenchy Silicone Announces Expansion on Silicone Tube Supplier Selection

Tenchy Silicone, a leading silicone tube supplier, is pleased to announce the expansion of its selection of products and services for customers. With over ten years of experience in the industry, the company has established a reputation for providing top-quality silicone tubes that meet customer needs and expectations. The new product line includes tubing from various manufacturers and offers a wide range of materials and sizes to accommodate every project.…

Tenchy Silicone Unveils their New Silicone Seal Gasket

Tenchy Silicone recently released a new silicone seal gasket designed to be used in a variety of industrial applications. It also provides excellent temperature insulation thanks to its ability to withstand temperatures up to 260 °C without any deformation or loss of strength, making it ideal for large-scale industrial projects. The silicone seal gasket is also unaffected by chemicals and ultraviolet light, making it suitable for numerous industries including automotive,…