Press release

Conformal Coatings Market Size will Observe Substantial Growth by 2026

Conformal Coatings Market for PCBs - SnapshotPrinted circuit boards (PCBs) form an integral part of any electronic device and serve as the foundation of a majority of electronic products. They are functional centers of most electronic devices and are used to connect various electronic components mounted on them, thereby forming an assembly or circuitry meant to perform various functions.

Conformal coatings are protective chemical coatings that protect electronic circuit boards from harsh environments that contain moisture, salt, or other contaminants. Conformal coatings ensure operational integrity of the electronic assembly by preventing it from voltage arcing, shorts, and static discharge. Generally, conformal coatings for the protection of printed circuit boards are based on acrylic, silicone, polyurethane, epoxy, parylene, etc.

View Report Preview:

https://www.transparencymarketresearch.com/conformal-coatings-pcbs-market.html

Acrylic conformal coatings can resist abrasion and can be easily applied or removed for repair or rework. They provide fair elasticity and are recognized for their high dielectric strength. Silicone conformal coatings provide superior chemical resistance and salt spray resistance. They are very flexible. Removal of silicone conformal coatings is quite challenging as it requires specialized solvents and long soaking time. Polyurethane conformal coatings are known for their superior resistance to moisture and chemicals. They offer high abrasion and excellent adhesion to a wide variety of substrates. Epoxy conformal coatings are generally available as two-part compounds. These conformal coatings provide resistance to humidity and high resistance to abrasion and chemicals. Once cured, they are very difficult to remove. Parylene conformal coatings are a special type of coating applied through vapor-phase deposition. They offer excellent dielectric strength and superior resistance to solvents and extreme temperatures. Fluoropolymer-based conformal coatings are generally dissolved in a fluorocarbon-based carrier solvent, and they are applied as a thin coat.

Solvent-based conformal coatings are used for coating applications owing to their cost effectiveness and ease of availability. Water-based technology is environmentally friendly, and manufacturers are striving to produce conformal coatings that employ water. The major advantage of water-based conformal coatings is reduced emission of VOCs. Use of UV-cured technology results in coatings that are VOC free and non-flammable. Conformal coatings are exposed to UV radiation for fast curing. UV-cured technology is employed for conformal coatings that are applied over PCBs exposed to harsh environments.

Conformal coatings are used for the protection of PCBs of consumer electronics appliances. In the automotive industry, PCBs are used in surrounding monitors, control systems, navigation systems (GPS), and audio and video devices. The coatings are used in factories and manufacturing facilities for protecting PCBs from harsh chemicals and rough handling. The medical applications of conformal coatings include monitors, scanning technologies, control systems, internal devices, scientific instrumentation, etc. In the marine industry, conformal coatings are used under the dash of high-performance boats and exterior equipment used on larger maritime systems. Conformal coatings in PCBs are also used in defense, aerospace, nanotechnology, and green energy technologies.

Aerospace applications of PCBs require a great deal of precision and durability as they operate in extreme conditions. Aircraft often go through significant amounts of turbulence in the atmosphere. Normal PCBs might get damaged during such harsh conditions. In order to avoid this, flexible PCBs are used in the aerospace industry.

Delamination in conformal coatings is the removal of the conformal coating from the surface of printed circuit boards. This process leaves the circuit board area exposed. Delamination is related to factors such as cleanliness, compatibility, permeability to moisture, degree of coating cure, etc. If the surface of the printed circuit board is contaminated, delamination of conformal coatings may occur due to poor adhesion of the coating to the laminate. Difference in surface energies of the coating and the substrate of PCB often leads to poor compatibility.

Key manufacturers such as Dow Corning, Henkel AG & KGaA, and Shin-Etsu Chemical Company Limited, with significant production capacities, dominate the global conformal coatings market. Large players are highly integrated, which helps them reduce production costs and gain a competitive edge in the market. Key players focus on new innovations and technologies in order to enhance their market share and serve diverse industries. These prominent companies have an advantage due to their extensive presence across the value chain, as compared to other manufacturers of conformal coatings.

Most consumer electronics devices are general-purpose devices, and thus, PCBs used in their fabrication need not be highly reliable. Quality and type of PCBs used depend on complexity of the circuit design. This affects the overall cost of the end-product.

Asia Pacific is a significant consumer of consumer electronics devices. Demand for PCBs is directly proportional to the demand for electronic devices. The consumer electronics sector in Asia Pacific was valued at around US$ 300 Bn in 2015. The sector in the region has been expanding at a rapid pace.

Request to view Sample Report:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=44288

Rise in population in the region, increase in disposable incomes of inhabitants of the region led by rapid industrialization, and availability of low-cost electronic devices and attractive finance schemes are some of the factors augmenting the demand for consumer electronics devices in Asia Pacific. This has resulted in increase in demand for PCBs in the region. Consumption of consumer electronics is high in countries such as China, India, and Indonesia. These countries offer significant potential for future expansion.

About Us

Transparency Market Research (TMR) is a market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. TMR’s experienced team of Analysts, Researchers, and Consultants, use proprietary data sources and various tools and techniques to gather and analyze information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact Us

Transparency Market Research

90 State Street, Suite 700

Albany, NY 12207

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Email: sales@transparencymarketresearch.com

Website: www.transparencymarketresearch.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Conformal Coatings Market Size will Observe Substantial Growth by 2026 here

News-ID: 1118720 • Views: …

More Releases from Transparency Market Research

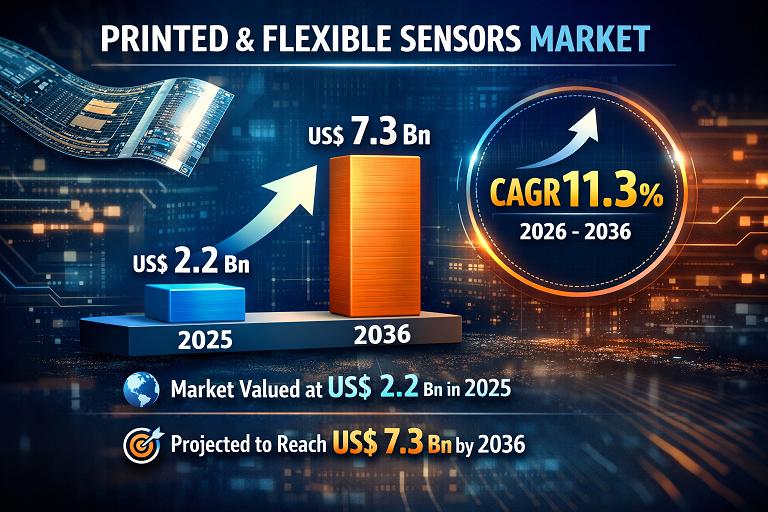

Printed and Flexible Sensors Market Expected to Reach USD 7.3 Billion by 2036 Dr …

The Printed and Flexible Sensors Market is demonstrating robust growth, driven by rising adoption of wearable electronics, smart healthcare devices, and flexible IoT-enabled systems. In 2025, the market size is estimated at approximately US$ 2.2 billion and is projected to expand at a compound annual growth rate (CAGR) of around 11.3 over the forecast period. By 2036, the market is expected to reach nearly US$ 7.3 billion, supported by continuous…

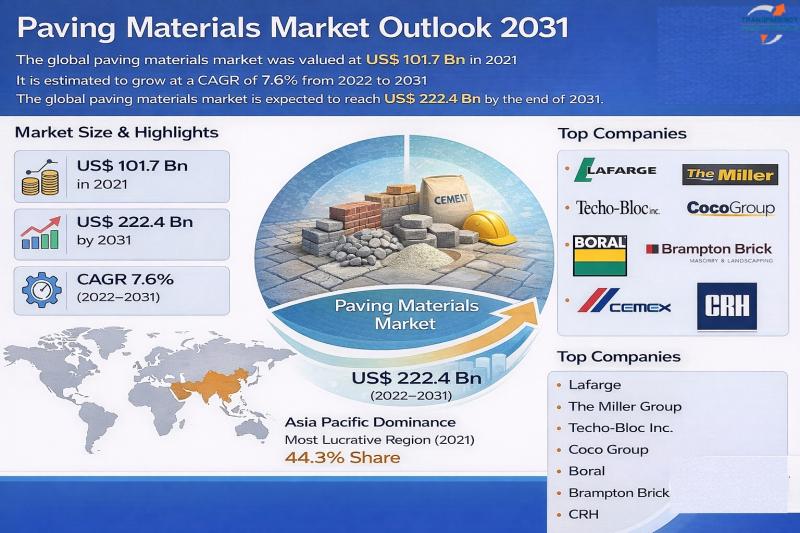

Paving Materials Market to Reach US$ 222.4 Bn by 2031, Expanding at 7.6% CAGR Dr …

The global paving materials market was valued at US$ 101.7 Bn in 2021 and is projected to expand at a CAGR of 7.6% from 2022 to 2031, reaching approximately US$ 222.4 Bn by the end of 2031. The market's robust growth is driven by rapid urbanization, expanding infrastructure development, increasing road construction activities, and rising investments in residential and commercial real estate projects across the globe.

Paving materials play a critical…

Magnetic Sensors Market to Reach US$ 9.8 Bn by 2036, Driven by Miniaturized High …

The global magnetic sensors market is poised for steady expansion, driven by advancements in sensor sensitivity, miniaturization, and the rising need for precision navigation systems across automotive, industrial, and consumer electronics sectors. Valued at US$ 6.4 Bn in 2025, the market is projected to reach US$ 9.8 Bn by 2036, expanding at a CAGR of 3.8% from 2026 to 2036.

Access key findings and insights from our Report in this sample…

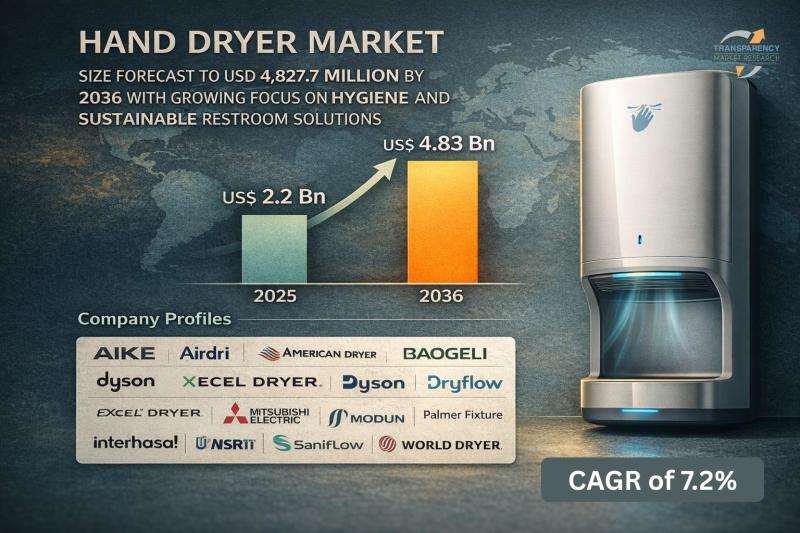

Hand Dryer Market Size Forecast to USD 4.83 Billion by 2036 with Growing Focus o …

Hand Dryer Market Outlook 2036

The global hand dryer market was valued at US$ 2.23 Billion in 2025 and is projected to reach US$ 4.83 Billion by 2036, expanding at a steady CAGR of 7.2% from 2026 to 2036. Market growth is driven by increasing emphasis on hygiene and sanitation, rising adoption in commercial infrastructure, and growing preference for eco-friendly and cost-effective hand drying solutions.

👉 Get sample market research report copy…

More Releases for PCB

Victory PCB Showcases High-Quality Double-Sided PCB Solutions for Modern Electro …

Victory PCB highlights the performance, flexibility, and cost-effectiveness of its double-sided printed circuit boards, designed to meet the demands of mid-complexity electronic systems.

Victory PCB, a professional printed circuit board manufacturer, continues to support modern electronics development through its high-quality double-sided PCB manufacturing solutions [https://www.victorypcb.com/products-category/double-sided-pcbs.html]. Designed to balance performance, reliability, and cost efficiency, Victory PCB's double-sided printed circuit boards are widely used across industries that require greater circuit density without the…

Victory PCB Expands Global Reach with Industry-Leading PCB Manufacturing & Assem …

Image: https://www.abnewswire.com/upload/2025/06/aa56d146ab76e34a4f335137dad3dd49.jpg

Victory PCB [https://www.victorypcb.com/], a global leader in printed circuit board (PCB) manufacturing and assembly, continues to set new benchmarks in high-quality PCB production, fast delivery, and customer service excellence. With a legacy of 19 years of innovation and precision manufacturing, Victory PCB is powering the next generation of industries, from automotive and medical equipment to aerospace and advanced communication devices.

Located in the heart of Shenzhen's modern Industrial Park, Victory…

Victory PCB: Pioneering Excellence in Global PCB Manufacturing and Assembly

Image: https://www.abnewswire.com/upload/2025/01/fabf105f8930f331e50cb1ca439637fe.jpg

Victory PCB [https://www.victorypcb.com/] is a renowned global manufacturer of PCBs and assembly services, recognized worldwide for its exceptional precision, innovation, and commitment to quality. With a client base exceeding thousands across various sectors, including automotive, aerospace, medical, industrial automation, and communication technologies, PCB solutions are tailored to meet each client's needs.

With centers covering as much as 30,000 square meters, Victory PCB employs over 450 staff dedicated to producing high-quality…

Victory PCB: Redefining Global Excellence in PCB Manufacturing and Assembly

Image: https://www.abnewswire.com/upload/2025/01/986e29984b844645f2a99a0a5e93a4c8.jpg

Having almost 20 years of expertise in producing and assembling printed circuit boards (PCBs), Victory PCB has established a solid reputation for providing high quality products, creative solutions, and consistent customer satisfaction. Victory PCB [https://www.victorypcb.com/], located in a contemporary 30,000-square-meter facility within Shenzhen's tech district, merges deep expertise with cutting-edge technology to manufacture products that bolster top industries worldwide. Relying on more than 1,000 clients and 80% of its…

Victory PCB Emerges as a Global Leader in PCB Manufacturing

Victory PCB has been delivering custom PCB solutions to global customers since 2005.

Image: https://www.abnewswire.com/uploads/3daf3e2d61300e7406f7fb61c56726fc.png

Victory PCB [https://www.victorypcb.com/], a professional printed circuit board (PCB) manufacturer established in 2005, is setting new standards in the global electronics industry with its commitment to top-quality, high-precision, and high-density PCB solutions. The solutions offered by Victory PCB, which exports 80% of its products worldwide, bridge the gap between concept and reality for clients in a variety…

PCB Ceramic Substrate Market Size, Share and Forecast By Key Players-Panda PCB T …

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- According to the MRI Team's Market Research Intellect, the global PCB Ceramic Substrate market is anticipated to grow at a compound annual growth rate (CAGR) of 13.62% between 2024 and 2031. The market is expected to grow to USD 21.58 Billion by 2024. The valuation is expected to reach USD 52.73 Billion by 2031.

The PCB ceramic substrate market is experiencing robust growth, fueled by the rising demand…