Press release

HARcad offers new interface for 3D tool

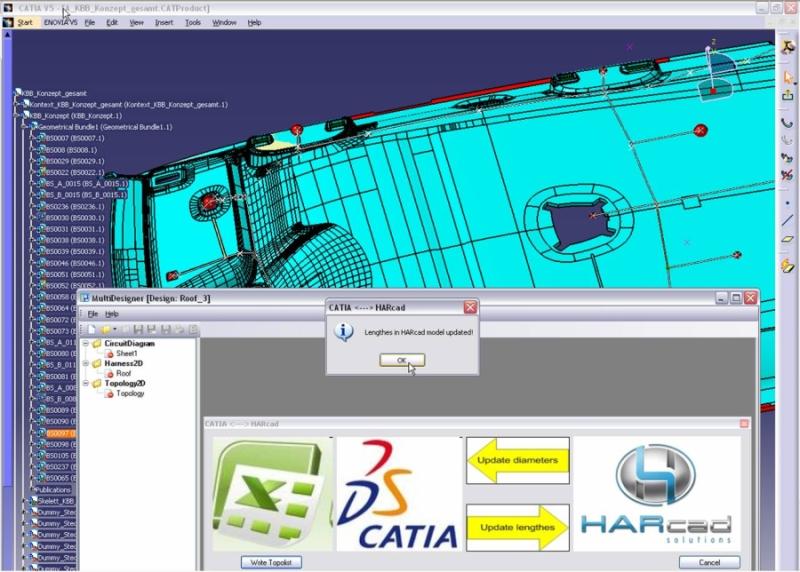

Wuerzburg, 27 November 2009. HARcad is now offering a new 3D DMU interface allowing the synchronization with CATIA V5. The use of the advantages of both systems increases the efficiency of the development process.Many companies are using two systems when developing wiring harnesses: HARcad as a dedicated design and engineering tool for wiring harnesses and in parallel e. g. CATIA V5 as 3D system for the laying of the bundle in the overall model.

The required segment lengths of the bundles are resulting from the mechanical design in the 3D tool. The data are transferred into the wiring harness development tool HARcad via a special interface. HARcad then identifies the according diameter based on the cable routing and considers worst case scenarios through all possible equipment variants. The harness diameters calculated in HARcad can now be imported into the 3D software and the required construction space can then be verified.

The implementation of the interface in HARcad and the therewith enabled exchange of information ensure efficient development and use the advantages of the DMU process and the wiring harness development. Beyond that Intedis offers its customers special consulting services to implement a field-proven process that also considers aspects of the change management.

HARcad supports the complex harness development processes from conceptual design to calculation and change process. The intuitive handling and the adjustment of the functionalities according to engineers’ requirements guarantee a short training period and fulfil the demand of time and cost efficiency. HARcad was developed by Intedis GmbH & Co. KG with headquarter in Wuerzburg, engineering partner and consulter supporting the leading automotive companies in all aspects of automotive electric/electronic architecture for several years. Due to the experience in the field of wiring harness development and the background of a leading wiring harness manufacturer, Intedis exactly knows the requirements harness engineers are challenged with in their daily work.

For more information please visit our website www.harcad-solutions.com or contact us via e-mail sales@harcad-solutions.com.

Press Contact:

Intedis GmbH & Co. KG

Anna Schleicher, Marketing & Communication

Delpstraße 4-8, 97084 Würzburg

Tel.: 0931-6602-35817

Fax: 0931-6602-35555

E-Mail: anna.schleicher@intedis.com

www.intedis.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release HARcad offers new interface for 3D tool here

News-ID: 108994 • Views: …

More Releases from Intedis GmbH & Co. KG

New version HARcad 3.1

Wuerzburg, 15 January 2010. Intedis has completed the preparations for the rollout of the new HARcad version 3.1. The extension of the software by 27 new functions is increasing efficiency and improving the data-consistency in the daily routine of harness developers.

The additional functions in HARcad are now, amongst others, allowing the integration of mechanical CAD systems or the wire/current simulation within the diagram module. In addition to the material cost…

New Simulation Module for HARcad

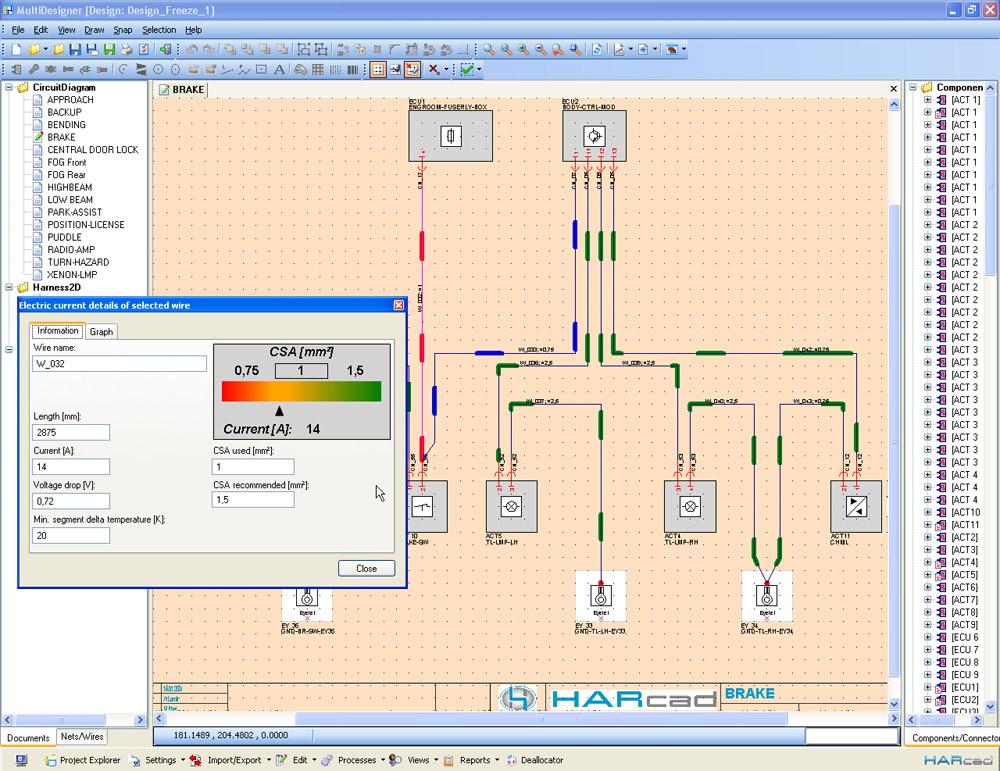

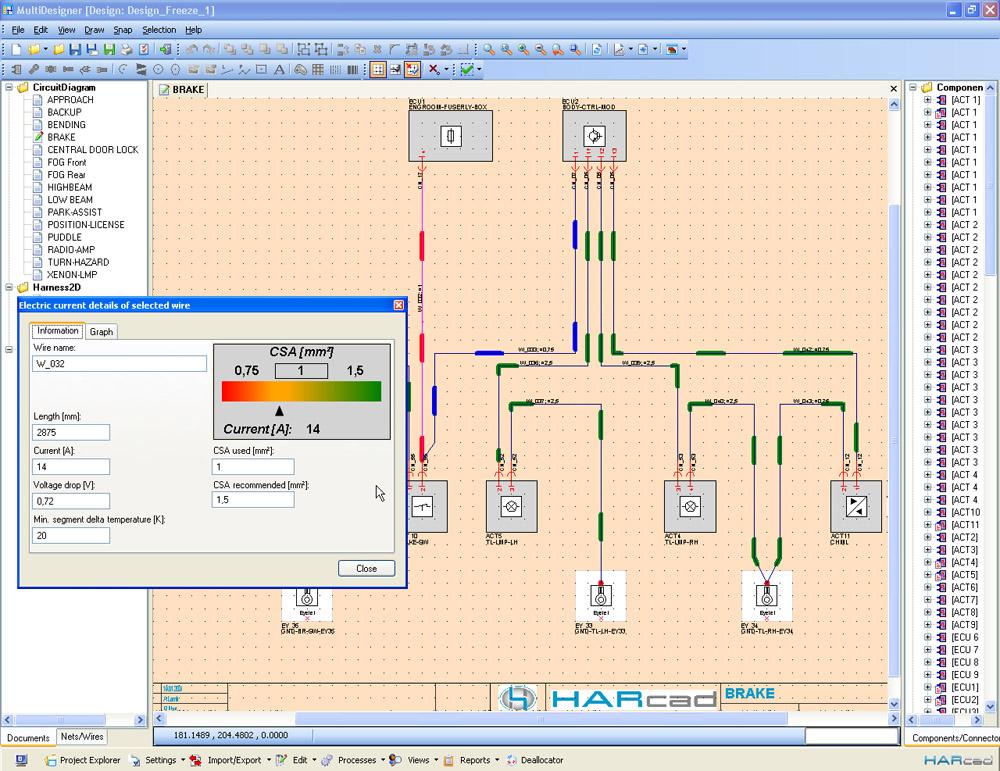

28 July 2009, Wuerzburg/Germany. HARcad, the harness development and engineering software, provides a new functionality which helps to avoid design errors and reduces costs and weight of harness systems.

Intedis offers a new simulation module for the HARcad users. This module brings simulation functionality into the circuit diagram-based design process. The resulting main benefit is the optimized dimensioning of wires, as the algorithm is simulating the current capacity…

HARcad enables the development of wiring harness systems according to ISO 9001

Wuerzburg/Germany. The harness development tool HARcad is a CAD application created specifically for the requirements covering harness products. After the successful launch on the German market, HARcad is now available in China.

HARcad supports the complex harness development processes from conceptual design to calculation and change process. The intuitive handling and the adjustment of the functionalities according to engineers’ requirements guarantee a short training period and fulfil the demand of time…

More Releases for HARcad

New version HARcad 3.1

Wuerzburg, 15 January 2010. Intedis has completed the preparations for the rollout of the new HARcad version 3.1. The extension of the software by 27 new functions is increasing efficiency and improving the data-consistency in the daily routine of harness developers.

The additional functions in HARcad are now, amongst others, allowing the integration of mechanical CAD systems or the wire/current simulation within the diagram module. In addition to the material cost…

New Simulation Module for HARcad

28 July 2009, Wuerzburg/Germany. HARcad, the harness development and engineering software, provides a new functionality which helps to avoid design errors and reduces costs and weight of harness systems.

Intedis offers a new simulation module for the HARcad users. This module brings simulation functionality into the circuit diagram-based design process. The resulting main benefit is the optimized dimensioning of wires, as the algorithm is simulating the current capacity…

HARcad enables the development of wiring harness systems according to ISO 9001

Wuerzburg/Germany. The harness development tool HARcad is a CAD application created specifically for the requirements covering harness products. After the successful launch on the German market, HARcad is now available in China.

HARcad supports the complex harness development processes from conceptual design to calculation and change process. The intuitive handling and the adjustment of the functionalities according to engineers’ requirements guarantee a short training period and fulfil the demand of time…