Press release

VERMES Microdispensing presents its modular, highly flexible MDS 3280 Micro Dispensing System for optimum adaptation to media and thus highest dispensing quality

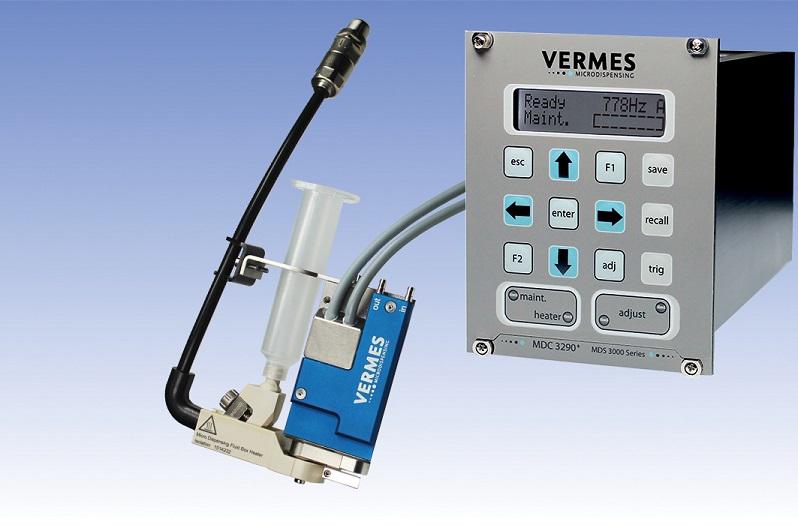

VERMES Microdispensing MDS 3280 Micro Dispensing System with new Bayonet Fluid Box Body for optimal substrate adaptation.

The contact-free, precise media allocation allows fastest cycle times. Fluidic part uncoupled from the valve drive reduces maintenance costs.

MUNICH, Germany, May 03, 2018 - VERMES Microdispensing, the world's leading manufacturer of precision dispensing systems, introduces its new MDS 3280 Micro Dispensing Solution of the MDS 3000 Series that convinces with applying ultra-precise application of smallest, identical droplets at highest speed.

The jet dispensing system MDS 3280 is based on the proven piezoelectric actuator with all the advantages of contact-free dispensing. To further enhance the extremely fine dispensing, especially for high and highest viscosity media, VERMES Microdispensing has expanded its MDS 3000 series with the MDS 3280 all-round system, which takes state-of-the-art microdispensing technology into new dimensions.

"The new MDS 3280 fits seamlessly into our current product portfolio and offers a multitude of applications, addressing all sectors that require high-performance dispensing systems and need to dispense in minimum quantities with maximum process reliability," says Juergen Staedtler, Managing Director of VERMES Microdispensing. "These include micro dispensing applications in automation and electronics, mechanical engineering, vehicle electrics, medicine, pharmacy, information technology and consumer electronics, as well as the related diverse component topography, particularly when combined with partially sensitive surface texture of the substrate," explains Juergen Staedtler.

The MDS 3280 is characterized by its new valve design ensuring highest performance, cost-effective productivity and excellent dispensing results with uniform and reproducible droplets. It is suitable for the exact application of a wide range of media, such as SMT adhesives, silver conductive adhesives, LED phosphors, underfill materials, as well as silicones, conductive glue or solder pastes and hot melts.

The ability to dispense droplets of less than 150 μm in diameter on the substrate with exceptional consistency and repeatability and shortest cycle times simultaneously improves throughput and reduces production costs.

The VERMES Piezojet valve MDV 3280 is equipped with a setting technology called "Top Adjust" and allows a quick and comfortable configuration and perfect and free pairing of nozzle insert and tappet. Parameter settings can be quickly and easily changed during operation. This allows the system to rapidly adjust to changing conditions such as variations in material viscosity, modifications of dispensing patterns and the application of different dispensing quantities.

The innovative connector technology which uncouples the fluidic part - named VERMES "Bayonet Fluid Box Body" - from the actual valve body, ensures flexible coupling between these two parts. This allows easy handling and quick cleaning since the screw-less Fluid Box Body can be removed from the valve drive with one-click.

This new, unique design makes the media supply rotatable and the very compact and lightweight valve can be perfectly adapted to a variety of tasks including the desired dispensing direction. It enables fast and seamless integration into the most inaccessible or confined spaces. When implementing complex applications, this saves valuable time and reduces set-up costs within fully automated microdispensing production processes. The tappet can be changed while the valve remains in its operating position, avoiding difficult part replacement and critical service outages.

The nozzle heater is integrated in the Fluid Box Body and keeps it constantly at optimum temperature without taking up much space. Due to the continuous temperature control and the control of the material pressure, the dispensing quality remains absolutely constant until the cartridge / container has been emptied.

VERMES Microdispensing world renowned high precision MDS Micro Dispensing Systems are the solution of choice for modern manufacturing processes throughout the globe in automotive, pharmacology, smart phones, TV sets, lamps, wafers, automated manufacture of LEDs, MEMS components, RFID tags, LC displays and many other electronic devices.

Headquartered in Germany, VERMES Microdispensing is an ISO 9001 certified company that revolutionized microdispensing technology with the introduction of its contact free piezo based MDS 3000 series in 2001. Today, the company is a world leader in the design and manufacture of innovative microdispensing concepts and systems for adhesives, silicones, greases, solvents and other fluids.

A world-class knowledge base, unparalleled design expertise, and extensive manufacturing capacity, enables the company to respond quickly and effectively to changing market conditions and the needs of its customers.

Our systems enable our customers to achieve contact free dispensing of highly viscous media droplets in the micro and nano-liter range at theoretical frequencies of more than 3000 Hz; a rate that is unique in our industry.

VERMES Microdispensing employees are dedicated to providing the best technologies and services to its customers around the world with the ultimate aim of contributing to increased throughput, improved quality and lower production costs.

Birgitt Harrow

VERMES Microdispensing GmbH

Palnkamer Str. 18

83624 Otterfing, Germany

Phone: +49 (0) 80 24-6-44-335

Fax: +49 (0) 80 24-6-44-19

pr@vermes.com

www.vermes.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release VERMES Microdispensing presents its modular, highly flexible MDS 3280 Micro Dispensing System for optimum adaptation to media and thus highest dispensing quality here

News-ID: 1044949 • Views: …

More Releases for Micro

Micro and Ultra-Micro Balances Market Size Report 2025

"Global Micro and Ultra-Micro Balances Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031" is published by Global Info Research. It covers the key influencing factors of the Micro and Ultra-Micro Balances market, including Micro and Ultra-Micro Balances market share, price analysis, competitive landscape, market dynamics, consumer behavior, and technological impact, etc.At the same time, comprehensive data analysis is conducted by national and regional sales, corporate competition rankings,…

Micro Mobility Revolution: Exploring the Growing Micro Cars Market

The term micro car is used for small-sized and lightweight cars, with an engine small than 700 cc. Bubble cars, cycle cars and quadricycles are defined as micro cars. This is usually three-wheeled and four-wheeled vehicle, available for personal and commercial usage. It is often used as a second or commuter car due to its low cost and fuel efficiency. This car is suitable for urban and suburban environment, as…

Micro Injection Molded Plastic Market worth $1,692 million by 2026 | Key players …

According to recent market research the "Micro Injection Molded Plastic Market by Material Type (Liquid-Crystal Polymer (LCP), Polyether Ether (PEEK), Polycarbonate (PC), Polyethylene (PE), Polyoxymethylene (POM)), Application and Region - Global Forecast to 2026", published by MarketsandMarkets, the micro injection molded plastic market is projected to reach USD 1,692 million by 2026, at a CAGR of 11.2% from USD 995 million in 2021.

Micro injection molded plastics are made of micro…

Micro Combined Heat & Power (Micro CHP) Market 2022 | Detailed Report

The Micro Combined Heat & Power (Micro CHP) research report combines vital data incorporating the competitive landscape, global, regional, and country-specific market size, market growth analysis, market share, recent developments, and market growth in segmentation. Furthermore, the Micro Combined Heat & Power (Micro CHP) research report offers information and thoughtful facts like share, revenue, historical data, and global market share. It also highlights vital aspects like opportunities, driving, product scope,…

Micro-Invasive Glaucoma Implants Micro-Invasive Glaucoma Implants

Global Micro-Invasive Glaucoma Implants Market Definition: Micro-invasive glaucoma implants is performed for the treatment of the open- angle glaucoma and is done through an ab- interno approach. It is very safe and provides faster recovery as compared to the traditional methods. They usually lower the intraocular by increasing the flow or reducing the production of the aqueous humor. Increasing cases of the glaucoma worldwide is the major factor fueling the…

Comprehensive Analysis On Micro Welding Equipment Market 2019 : Pro-Fusion, OR L …

Up Market Research added a new Micro Welding Equipment Market research report for the period of 2019 – 2026. Report focuses on the major drivers and restraints providing analysis of the market share, segmentation, revenue forecasts and geographic regions of the market.

Get Sample Copy Of This Report @

https://www.upmarketresearch.com/home/requested_sample/108038

The report contains 112 pages which highly exhibit on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing…