Press release

Automated sealant dispensing proves a winner for innovative golfing product

Shot Scope Technologies, based in Edinburgh, designs and manufactures innovative wearable technology which helps both professional and amateur golfers to improve their game. A keen golfer with a background in electronics design, CEO David Hunter set up the company in 2014 to develop the golf wearable, which collects and analyses over 100 key statistics from each round played, identifying shots, club used and GPS information. The data can then be easily uploaded to any smartphone or tablet (via an app) or computer.David’s team was looking for an effective way to seal the back of the device to the main body. Apart from the obvious need to prevent the ingress of water and dirt, it was also necessary to deal with humidity: playing in the sunshine of the Costa del Sol on one day followed by a round on a damp Scottish course the next could result in misting on the inside of the display screen. Stamping or printing a pre-formed gasket was considered, but thought too challenging owing to the thin 0.5mm gasket width. Manual dispensing of a silicone sealant was also rejected as being too tricky to get an accurate and tidy application.

Both David and subcontract manufacturer Greenfold Systems’ Ian Kennedy were well aware of the benefits of automation, and contacted two potential suppliers.

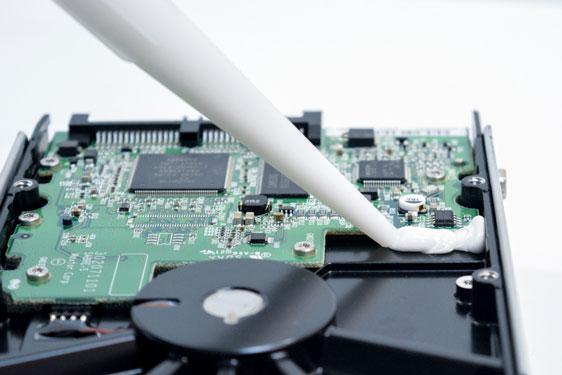

Having discussed Shot Scope’s requirements, Intertronics recommended a cost-effective combination consisting of an F5200N.1 gantry robot, 790HP-LF high pressure dispensing valve controlled by a SL101N digital liquid dispenser, and 310ml dispensing cartridge holder for the material feed – all manufactured by its partner Fisnar. This setup applies a single part RTV silicone, non-corrosive and suitable for electronics applications, which is supplied by Intertronics to Greenfold. The precisely applied silicone bead seals the unit.

David recalls the specification and buying process: “It seemed like a good solution and was within our budget. Intertronics understood what we were looking for, and sent us a couple of videos of applications similar to our own, together with some samples of dispensed liquid form-in-place gaskets.” He adds: “We declined the offer of a face-to-face demonstration as we were happy that the setup would do what we needed and that Intertronics would have the expertise to set the whole thing up.”

The curvature of the back of the wristband demanded robotic movement in the x, y and z axes. The equipment was purchased by Shot Scope, delivered to Greenfold Systems and set up quickly and easily by Intertronics’ Paul Whitehead. Six backs are placed in a jig and the sealant is applied in under a minute, prior to hand-assembly to the unit’s body.

Once the dispenser, valve and robot had been set up and working for a short time, Paul returned to refine the movement path and increase the speed.

Shot Scope’s initial run was 1,250 units and they have increased production to 5,000 devices per quarter at the time of writing.

David has been impressed with both Intertronics as a supplier and indeed, the entire process. “The service has been excellent, from getting to know our requirements to the short time taken to program the machine and show us a good sample, then investing the time in improving the process itself.”

He summarises the main benefits of the system as faster manufacturing time, reduced labour costs, a consistently high-quality result with no defects or wasted material.

Paul, a keen golfer himself, enjoyed working on this project: “With Shot Scope, the combination of GPS and live performance tracking in one wearable package is a great aid to lowering one’s handicap.

For further information please see www.intertronics.co.uk/case-studies/ or visit the Intertronics blog at www.intertronics.co.uk/blog.

Intertronics supplies adhesives, coatings, sealants and equipment to customers with high technology, high performance assembly applications. Their customers are manufacturers in industries such as electronics, medical devices, plastics, optical, automotive, energy, defence and aerospace.

Intertronics

Unit 17, Station Field Industrial Estate

Banbury Road

Kidlington

Oxfordshire, OX5 1JD

Tel: 01865 842842

email: info@intertronics.co.uk

www.intertronics.co.uk

Press contact: Peter Swanson

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Automated sealant dispensing proves a winner for innovative golfing product here

News-ID: 1032333 • Views: …

More Releases from Intertronics

Tidy workplace and precise dispensing results from preeflow® eco-PEN450 for Fra …

Franklin Electric, a leading international manufacturer of water and fuel pumps, faced a difficult challenge when tasked with optimising dispensing processes at their Czech production site.

The objective was to reduce the waste of UV curing material during the application process. Dispensing equipment previously used by Franklin Electric had been very inaccurate, creating unnecessary waste, high material costs and additional cleaning efforts.

After completing preliminary tests, the team at Franklin Electric were…

WACKER ELASTOSIL® N9111 tin free silicone from Intertronics avoids conflicting …

WACKER ELASTOSIL® N9111 from Intertronics is a tin-free single part RTV silicone adhesive sealant, with a neutral cure chemistry, producing a non-corrosive seal that does not inhibit other materials such as platinum cure silicones. This, along with its UL94 V-0 rating, makes it a strong candidate for electronics manufacturing, especially for gap filling, component ruggedisation, and form-in-place gasketing. It is stocked in depth at Intertronics for next-day delivery.

Elastosil N9111 is…

preeflow precision dispensing system from Intertronics improves quality and redu …

The automobile manufacturing industry places high demands on suppliers with regard to process reliability, quality and efficiency. To meet these challenges, a preeflow customer had to optimise his application of a two-part sealant to make a form-in-place (FIP) gasket. In his previous process, the dispensed sealant bead exceeded the tolerance limits at the point where the gasket loop completed and the sealant overlapped itself. In addition, a key process variable…

New guidance from Intertronics – How to specify a dispensing robot to increase …

Automated application of adhesives, potting compounds or encapsulants, sealants, FIP gaskets, temporary masking, lubricants, or other liquids, fluids or pastes provides productivity benefits over manual application, including consistency, speed and accuracy. As selection of a dispensing robot is sometimes a daunting task, Intertronics, a specialist adhesives and dispensing company, has compiled a short piece of guidance on how to specify a dispensing robot. The full guidance can be found on…

More Releases for Scope

Glutathione Market Future Scope Analysis with Size, Trend, Opportunities, Revenu …

The glutathione market size was valued at USD 2.58 Billion in 2024 and the total revenue is expected to grow at a CAGR of 12.87 % from 2025 to 2032, reaching nearly USD 6.8 Billion.

Glutathione Market Overview:

The Glutathione Market is witnessing robust growth driven by the increasing awareness of its powerful antioxidant properties and its rising application across pharmaceuticals, cosmetics, and nutraceuticals. Glutathione plays a vital role in detoxification, immune…

Fox Scope Reviews: Truth About Fox Scope Revealed

Fox Scope is a cutting-edge optic designed to enhance your shooting experience by combining innovative technology with precision engineering, this advanced scope delivers exceptional performance in various shooting applications.

Fox Scope is a high-performance device that features crystal-clear, adjustable magnification and illuminated reticles, allowing for rapid target acquisition and precise aiming. The generous eye relief and HD clarity ensure a comfortable shooting experience, while the Mil-Dot crosshairs provide precision capability.

Fox Scope's…

AI in Education Market Scope, Trends, and Growth Forecast | Scope By 2032

The AI in Education Market is Valued USD 3.2 billion in 2022 and projected to reach USD 54.4 billion by 2032, growing at a CAGR of 42.7% During the Forecast period of 2025-2032.

The Latest Market Research report on "Global AI in Education Market Report 2025 - Future Opportunities, Latest Trends, In-Depth Analysis, and Forecast to 2032" provides strategic insights into the global AI in Education market, including market size estimates…

Composable Infrastructure Market Scope, Trends, and Market Size | Scope By 2032

The Composable Infrastructure Market is Valued USD 4.339625 Billion in 2023 and projected to reach USD 32.3 billion by 2032, growing at a CAGR of 25.0% During the Forecast period of 2025-2032.

The Latest Market Research report on "Global Composable Infrastructure Market Report 2025 - Future Opportunities, Latest Trends, In-Depth Analysis, and Forecast to 2032" provides strategic insights into the global Composable Infrastructure market, including market size estimates (Volume - Million…

Dermatome Devices Market Size, Scope: Evaluating Share and Scope for 2024-2031

United States, New Jersey: According to Verified Market Research analysis, the global Dermatome Devices Market size is reached a valuation of USD 161.67 Million in 2023, with projections to achieve USD 241.96 Million by 2031, demonstrating a compound annual growth rate (CAGR) of 5.17% from 2024 to 2031.

The Dermatome Devices Market encompasses medical instruments used in dermatology and plastic surgery procedures to precisely remove thin layers of skin for grafting…

Solvents Market Size, Scope: Evaluating Share and Scope for 2024-2031

United States, New Jersey: According to Verified Market Reports analysis, the global Solvents Market was valued at USD 23.5 billion in 2023 and is expected to reach USD 50.01 billion by the end of 2031 with a CAGR of 6.73% During the Forecast Period 2024-2031.

Solvents are substances capable of dissolving or dispersing other substances to form homogeneous solutions. They find extensive use across various industries, including paints and coatings, pharmaceuticals,…