Press release

Guyson’s Customers Benefit from Showroom Update

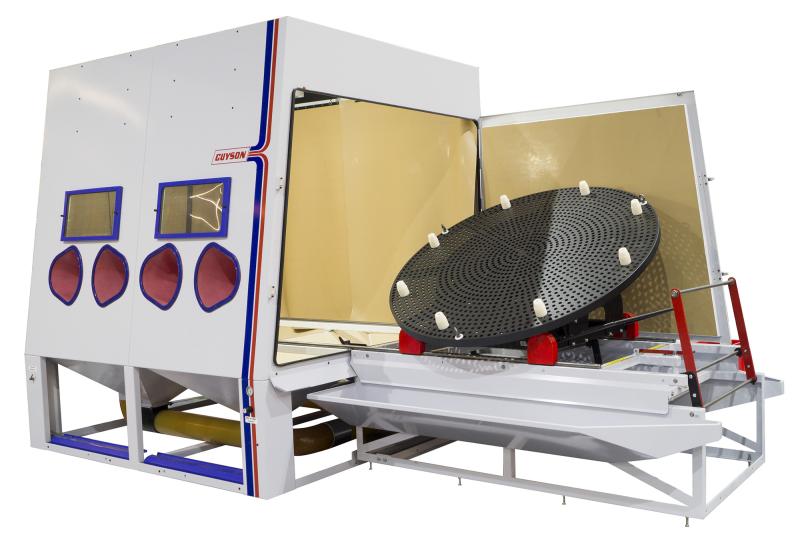

Leading industrial finishing equipment manufacturer Guyson International has recently updated the showroom facilities at its manufacturing site in Skipton, North Yorkshire to better reflect the extensive range of manual blast cabinets it sells and to now showcase its Additive Manufacturing component finishing expertise with the stand backdrop used at the last TCT show also on display.Customers visiting the company’s vast showroom can be walked through the range of standard Formula and Euroblast® suction fed manual blast cabinets, trying each out for size. These blast cabinets are complimented with a range of matching dust collectors; some fully connected up to their blast cabinet to show complete systems.

Application specific blast systems on display in the showroom include: the Euroblast 8GL – for decorators of sheet glass and designed to handle most sizes and weights of flat glass; typical usage includes frosted windows, internal glass panels, door panel decoration, decorative insignia and corporate branding. Also the Guyson Wheelmaster – designed for blast etching alloy wheels, and incorporates many application specific handling features that enable the operator to use this wheel blasting system safely, without heavy lifting.

Any ‘missing sizes’ in the showroom display from the full Guyson range, can be tried for real, along with a range of pressure fed Euroblast versions, in Guyson’s extensive ‘Component Finishing Centre’ which incorporates the customer demonstration area and R&D development facilities. Guyson offers a free, no obligation test and evaluation service to all prospective customers

"Comprehensive testing of actual customer products is the only way to truly establish the correct blasting, washing and precision cleaning parameters and equipment that Guyson would recommend to customers”, states John Jackson - Guyson's Customer Service Manager, who is responsible for the Component Finishing Centre.

Guyson’s additive manufacturing finishing credentials are highlighted in the eight metre wide flexible display unit that is incorporated to the rear of the showroom. Here is shown information and a 3D rendering of the company’s latest robotically controlled finishing station and powder recovery system which will bring the user time and financial savings, and operational safety benefits over their current manual operations. This exciting new development for the AM sector incorporates the best of Guyson’s long standing automated robotic blasting technology coupled with Guyson’s technology partner Russell Finex’s sieving and screening expertise.

For petrol heads the showroom also includes team Guyson’s Ginetta G40 club car, which is driven by Jimmy Thomson, the owner’s eldest son, in the British GT-supporting Ginetta Racing Drivers Club series of races. Additionally there is the unique Guyson E12 based on the Jaguar V12 E-type, with bodywork styled by the well-known British car designer William Towns and a classic 1911 Sizaire-Naudin open topped sports car.

If you wish to visit Guyson’s showroom and undertake free finishing trials on your own components please call 01756 79911 or email info@guyson.co.uk now.

About Guyson

Guyson International Limited is a privately owned family company with a world-wide reputation for excellence in the design and manufacture of blast finishing, spray wash and ultrasonic cleaning equipment. Formed 80 years ago, the company is registered to BS EN ISO 9001: 2008 and BS OHSAS 18001:2007 and its head office is located at Skipton, North Yorkshire, in the north of England. Guyson has four international subsidiary companies: Guyson Corporation of the USA, located in Saratoga Springs, New York State; Guyson SA, situated near Paris, France; Guyson Sdn Bhd in Penang, Malaysia; and Guyson CN, in Wuxi, Jiangsu Province, China.

Guyson International Limited

Snaygill Industrial Estate, Keighley Road,

SKIPTON, North Yorkshire, England BD23 2QR

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Guyson’s Customers Benefit from Showroom Update here

News-ID: 988441 • Views: …

More Releases from Guyson International Ltd

Extra-Large Blast Machine for Blast Etching Aerospace Rings

Guyson International, the UK's foremost industrial finishing equipment manufacturer, has installed a Guyson Euroblast® 2-metre PF (Pressure Fed) blast system into a division of a leading European aerospace company. The extra-large blast cabinet is used to deliver a uniform etched key surface on a range of machined circular aluminium rings prior to bonding.

After blast trails performed at the company's Skipton demonstration centre, a Euroblast 2-metre PF blast system (2.1…

Guyson Twin Spindle Blast Machine for Etching Tubular Components

Guyson International, the UK's leading manufacturer of industrial finishing equipment, has recently manufactured and installed into a UK manufacturing company an automated Multiblast RSB twin spindle blast system for externally blast etching various sizes of tubular components. This new blast system incorporates two rotating blast stations with matching top clamps, to hold the product securely, whilst two vertically traversing blast guns produce a uniform blast etch finish over the length…

Guyson Staff Clock-Up 180 Years!

At Guyson International's Skipton headquarters, Monday 15th August saw rain, much needed, and celebrations, much deserved. Employees from the company's blast and wash division gathered outside to congratulate seven employees who were awarded long service awards. And between them amassed a total of 180 years of service at Guyson, with one, Keith Miller celebrating 50 years of service.

In typical unpredictable UK weather, after so many days of bright hot sunshine,…

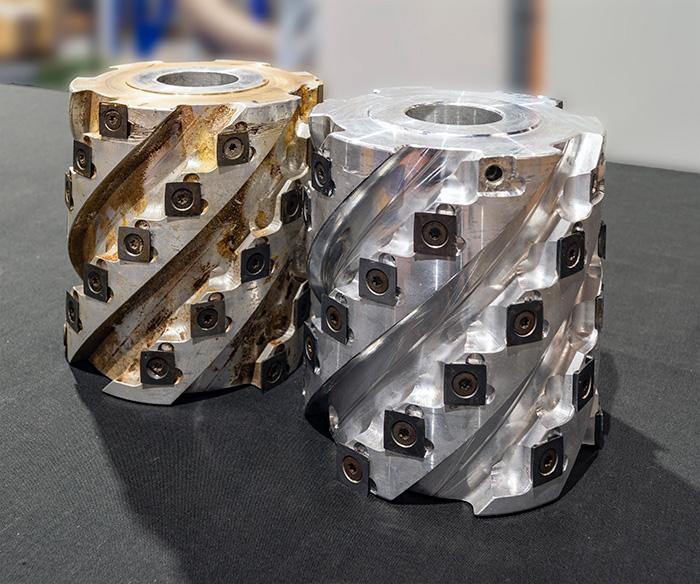

Guyson Equipment Cleans and Maintains Planing and Woodcutting Tools

Guyson International, one of the UK's leading manufacturers of industrial finishing equipment, recently delivered a KS450 ultrasonic cleaning tank and a Formula 1200 benchtop bead blast cabinet to RHW (R H Wilson (Lakes) Ltd.) of Kirkby Stephen, a leading timber importer and supplier, for cleaning and maintaining their wood cutting and planing tools.

The problem was how best to clean 'helical planer blocks' to remove a build-up of pitch, sap, resin…

More Releases for Guyson’s

Guyson’s New Ultrasonic Cleaning Baths Deemed a Great Success

Guyson International, the UK’s foremost industrial finishing equipment manufacturer is claiming their new GUK benchtop ultrasonic cleaning baths a great success and has enabled Guyson to reach new categories of customers with its wide range of tank sizes and highly competitive pricing. The new larger tank versions of 30 and 45 litres have proved especially popular.

After launching their extensive range of ultrasonic cleaning baths just over a year ago, replacing…

Guyson Blast Cabinet Etches Busbars

Guyson International, the UK’s foremost industrial finishing equipment manufacturer, has recently installed a specially configured Guyson Euroblast® 7PF (Pressure Fed) blast cabinet into one of the world’s leading designers and manufacturers of switchgear and instrumentation. The cabinet is to provide a blast etched surface, on their range of high voltage busbars, to improve adhesion of a special non-conductive coating.

The company’s existing blast cabinet system had suffered from several operational…

New Guyson ‘Standard Blast Products’ Brochure

To kick off the New Year, Guyson International, the UK’s leading industrial finishing equipment manufacturer, has just issued a new ‘Standard Blast Products’ brochure that all in one place showcases its comprehensive range of ‘standard’ blast cabinets. This glossy twelve page brochure features their premium ATEX rated blast cabinets, its professional Euroblast® range, light industrial Formula cabinets and specialist alloy wheel refurbishment cabinets.

Potential customers are invited to use the…

Guyson SafeContractor Accredited

Leading industrial finishing equipment manufacturer Guyson International has received accreditation under the Alcumus SafeContractor scheme, which is accredited by UKAS, the UK’s national accreditation body for certification providers and they are also a member of SSIP (Safety Schemes in Procurement), ensuring that their accreditation services also follow best practice.

The scheme recognises excellence in health and safety management and confirms that Guyson’s health and safety processes have been externally assessed to make…

Guyson to Release Details of Powder Recovery System at TCT 2017

Leading surface finishing equipment manufacturer Guyson International will be releasing details of their latest powder recovery system, aimed at additive manufacturers with powder based systems, at the forthcoming TCT + Personalize show which is held at the NEC from the 26-28th September 2017. Alongside, Guyson will be showcasing its range of ‘surface finishing stations’. This exhibition covers all aspects of 3D printing, additive manufacturing (AM) and rapid prototyping and to…

Guyson's ‘New Look’ Reflects Long Motor Sports Heritage

Leading industrial finishing equipment manufacturer Guyson International has recently updated its blast cabinet decals and colour ways. Inspired by the modern industrial market places seeming preference for lighter coloured machine tools the new look incorporates visual symbolism reflecting the company’s long motor sports heritage by the adoption of sporting stripes on the machines.

Guyson is currently visually rebranding all it blast cabinets, including the light industrial Formula range, the Euroblast® premier…