Press release

Efficient wafer handling with the latest vacuum technology

The IHP – Innovations for High Performance Microelectronics – in Frankfurt (Oder), Germany is a member of the Leibniz Association. It performs research and development in the fields of silicon-based systems, highest-frequency integrated circuits and technologies for wireless and broadband communication. The focus of research at the institute is oriented towards issues relevant for business and results in applications for telecommunications, semiconductor and automotive industries, aerospace, telemedicine, and automation technologies. The institute has developed into an internationally recognized competence centre for silicon-germanium technologies. The IHP chose a state-of-the-art centralized vacuum system from the company Dr.-Ing. K. Busch GmbH to supply the vacuum for the clean room building. The fully-automatic vacuum system supplies up to 80 vacuum consumers with the vacuum needed in the different departments to hold or handle wafers.The IHP provides an important bridge between academia and industry. The Joint Labs, with universities and universities of applied sciences in the Berlin-Brandenburg region, have been particularly successful in this cooperation. As a public research institute, it is funded by the state of Brandenburg and the German Federal Government. The IHP employs 300 employees from over 20 countries. About half of the employees are scientists, mainly engineers and physicists, who conduct interdisciplinary and application-orientated research. The heart of the innovative research facility is the clean room building with 1,000 square meters of class 1 clean room area where wafers are prepared under conditions similar to those in the industry. Here, pilot production of wafers is developed for analyzing possible subsequent industrial manufacturing. There is a total of 80 vacuum consumers in all of the clean rooms for wafer production. These can simply be vacuum tweezers that employees use manually for visual inspection of the wafers, for example. Handling equipment for transporting the wafers or for putting them down in a defined spot for further processing are also connected to the facility’s vacuum network. Furthermore, different vacuum holding devices on the microscope are used in etching and coating processes, or in lithography systems.

A vacuum supply consisting of three identical liquid ring vacuum pumps had been in operation since moving into the new building in the East-Brandenburg technology park in Frankfurt (Oder) in 1999. However, the team at the IHP was not really satisfied with this solution. For one, these vacuum pumps required water as an operating fluid. Decalcified, demineralized water was used in this case, which required a certain degree of effort and incurred associated costs. Secondly, these vacuum pumps were not adjustable and thus consumed unnecessary energy because they were not able to be adjusted to the actual vacuum requirements. Because all process steps in the clean rooms depend on the central vacuum supply, the team was also worried about reliability, especially as the supply reliability for spare parts became increasingly critical.

So in 2016, they began looking for a trend-setting vacuum technology that was state of the art, could be operated as economically as possible and guaranteed the highest degree of reliability.

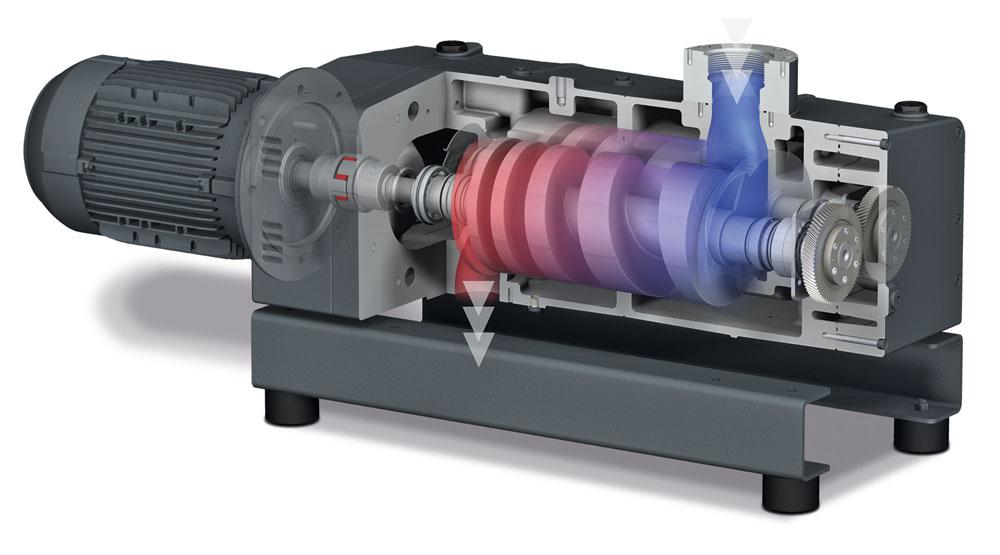

They selected a vacuum system with three COBRA NX screw vacuum pumps from the company Dr.-Ing. K. Busch GmbH. In December 2016, this system was installed in a step-by-step process – pump by pump – while the system was in operation and the existing liquid ring vacuum pumps were dismantled.

COBRA NX screw vacuum pumps use dry compression, so they do not need any operating fluid for the vacuum generation. This vacuum technology allows a contact-free operation. Two screws rotate in opposite directions and do not come into contact with each other or the housing. The gap here is so small that no operating fluid is needed for sealing. This technology also has the advantage of being absolutely maintenance-free, meaning that there is no need to replace wearing parts.

The speed of all three of the installed COBRA NX screw vacuum pumps can be controlled and operated according to demand. This ensures that the only vacuum pumps in operation are the ones that are actually needed to maintain the vacuum level of 50 to 60 millibars. The size of the vacuum system is such that two COBRA NX vacuum pumps at 100% output are sufficient for full load operation. The third vacuum pump serves as a stand-by to increase reliability. The control system ensures that all three vacuum pumps have the same number of operating hours so that they are evenly loaded. The control system is self-sufficient and guarantees that the required vacuum level is constantly maintained. In turn, the self-adjusting control system is connected to building control technology, which registers any problems that may occur and can be used to call up different parameters.

The vacuum system operates around the clock all year long. It is part of the clean room building facilities and located on the ground floor together with other supply tools like the compressed air supply, cooling water processing, fume scrubbers or power supply units. All these supply units are located in one clean room. Additional systems such as radiators, chillers and transformers are located on the first floor while the actual core area of the clean room building is on the second floor; this is where all the process steps for preparing the wafers are located.

After just the first few months, they already saw a 40 percent reduction in operating costs. This was possible because COBRA NX screw vacuum pumps require less motor power due to their high efficiency factor; therefore, they can function with smaller motor sizes than liquid ring vacuum pumps. Speed control enables exact adjustment to the actual needs; speed control is not possible for liquid ring vacuum pumps for technical reasons. In addition, the costs for water as an operating fluid and all the associated energy costs for its preparation and circulation no longer apply. It was thus possible to make the vacuum supply much more economical and reliable at the same time by using state-of-the-art vacuum technology from Busch.

About Busch:

Busch Vacuum Pumps and Systems is one of the world’s largest producers of vacuum pumps, vacuum systems, blowers and compressors.

Its extensive product portfolio comprises solutions for vacuum and overpressure applications in all industries, including the chemical, semiconductor, medical technology, plastics, and food sectors. It also covers the design and construction of customized vacuum systems, as well as a global service network.

The Busch group is a family-owned company and is still managed by the Busch family. Busch Vacuum Pumps and Systems has 3,000 employees in more than 60 companies in over 40 countries worldwide. Busch is headquartered in Maulburg, in southwest Germany. This is the location of Busch SE headquarters, as well as the German production facility and German sales company. In addition to Maulburg, Busch also has its own production plants in Switzerland, the UK, Czech Republic, Korea and the USA.

History:

Busch Vacuum Pumps and Systems was founded by Dr.-Ing. Karl Busch and his wife Ayhan Busch in 1963. Dr.-Ing. Karl Busch developed the “Huckepack”, which was the first vacuum pump that could be used for vacuum packaging of foodstuffs. The follow-up product, the compact “R 5” rotary vane vacuum pump, revolutionized food packaging. A further milestone represented the development of the “COBRA” screw vacuum pump. In 1971 the international expansion of the Busch group started with the founding of a sales company in the UK. The first production plant outside Germany was established in the USA in 1979.

Contact:

Busch Vacuum Pumps and Systems

Schauinslandstraße 1

79689 Maulburg

Telephone: +49 (0) 7622 681 3376

jasmin.markanic@busch.de

www.buschvacuum.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Efficient wafer handling with the latest vacuum technology here

News-ID: 959036 • Views: …

More Releases from Busch Dienste GmbH

Liquid ring vacuum pumps – Classic vacuum technology and yet still state of th …

Vacuum technology has never stopped developing – not only in the recent past, but for decades it has continued to progress. Today, dry screw vacuum pumps are used in chemical processing technology and many other applications just as dry claw vacuum pumps have established themselves as standard vacuum generators in entire branches of industry. Oil-lubricated rotary vane vacuum pumps are also state of the art in many applications, not least…

Proven vacuum technology fit for Industry 4.0

Busch Vacuum Pumps and Systems enjoyed a great deal of interest from an audience of experts at the IFFA in Frankfurt. The vacuum technology specialist showcased its latest products for the vacuum packaging of meat and sausage products and for meat processing.

Busch also premiered the new R 5 PLUS rotary vane vacuum pump, which is prepared for Industry 4.0. This innovative vacuum pump is based on proven rotary vane vacuum…

Busch solutions for Industry 4.0 at ComVac

The Busch Vacuum Pumps and Systems trade show appearance received a great response from visitors to ComVac, the leading international trade show for compressed air and vacuum technology, held in Hanover, Germany. The interested trade show crowds were able to discover the topic of Vacuum 4.0 and the best-fitting innovative vacuum solutions at Busch.

Numerous visitors took the opportunity to talk to the Busch vacuum experts. With Vacuum 4.0, Busch is…

Dry vacuum systems for centralization of vacuum supply

The concept, design and realization of central vacuum supplies is one of Busch Vacuum Pumps and Systems' core competencies. Thousands of such vacuum systems are in operation worldwide. A wide range of operating principles for generating vacuum in the individual pump modules are applied. In addition to oil-lubricated R 5 rotary vane vacuum pumps, dry-compressing vacuum modules can be used, for example in vacuum systems with COBRA NX screw vacuum…

More Releases for COBRA

ATEQ Aviation and Cobra Systems Welcome Susan Johnson

ATEQ Aviation and Cobra Systems are happy to welcome new Product Specialist, Susan Johnson. Susan will handle inside sales for Cobra Systems and work closely with ATEQ's marketing coordinator, Heidi Franklin, on communication initiatives.

"I am thrilled to have someone on board with years of communications experience to assist me with marketing the new ATEQ-Cobra brand," said Franklin.

Susan's entire career has been in the aviation industry which began with obtaining her…

Legal Process Outsourcing Services Market Competitive Analysis 2017-2025 : Clutc …

Global Legal Process Outsourcing Services Market: Snapshot

The wave of outsourcing has swept across a wide spectrum of industries world over, and the law industry is no different. The key motivations for outsourcing in various sectors has been cost-savings and reduced risk factors in the backdrop fiercely competitive landscape. Adoption of legal process outsourcing (LPO) services has enabled the players in the industry to embark on cost-saving measures while focusing on…

ATEQ and Cobra Systems Welcome Krystle Abbott

ATEQ Aviation, along with Cobra Systems, is pleased to announce the addition of a new Office Manager, Krystle Abbott. Cobra Systems, located just outside of Chicago, Illinois, welcomed Abbott to the team in early August. She will be responsible for the overall operations of Cobra Systems. Everything from property management, administration and IT to accounting, purchasing, and human resources.

Abbott has an extensive background in the healthcare industry. She started…

COBRA: Blockchain banking beyond crypto

SYDNEY, AUSTRALIA, 21 March 2018

Whilst incredible stories of financial gain and, more recently loss, have been attributed to crypto currencies, the real story behind crypto is the need for an overhaul of our banking system.

What has driven the rise in crypto popularity is, fundamentally, the requirement for better access to banking facilities, the need for more flexibility in banking products, the expanded need for international banking, and…

Urbane Living: Cobra Wallcoverings

London – May 12, 2017. Make a statement whilst celebrating sustainable craftsmanship with Urbane Living’s Cobra wallcoverings collection.

Taking inspiration from the natural world but with an unusual twist, the Cobra collection references the shimmering effect of light on reptile skin. With colours and textures evoking the earthy tones of the crocodile and the turtle, to the precious jewel tones of exotic snakes and lizards, these wallcoverings are a…

Global Walkie Talkie Market - Midland, Cobra, Wintec, Icom, Hytera, Kirisun

Apex Research, recently published a detailed market research study focused on the "Walkie Talkie Market" across the global, regional and country level. The report provides 360° analysis of "Walkie Talkie Market" from view of manufacturers, regions, product types and end industries. The research report analyses and provides the historical data along with current performance of the global Walkie Talkie industry, and estimates the future trend of Walkie Talkie market on…