Press release

Enabling Safe and Efficient On-Stream Pipeline Inspection with Computed Radiography

Mozzat Enterprise Sdn Bhd (MESB), located in Brunei with around 200 employees, provides a wide range of NDT on-stream inspection services to the local oil and gas industry, primarily to Brunei Shell Petroleum, as well as to other companies in the surrounding region. MESB has various certifications, including ISO 9001, ISO 14001, BS OHSAS 18001 and was the first local company in Brunei to achieve ISO/IEC 17020 certification from ANSI-ASQ National Accreditation Board (ANAB) in the United States.MESB has been using the DÜRR NDT HD-CR 35 NDT scanner since 2014 for corrosion monitoring and during this time has processed more than 5000 images with the system.

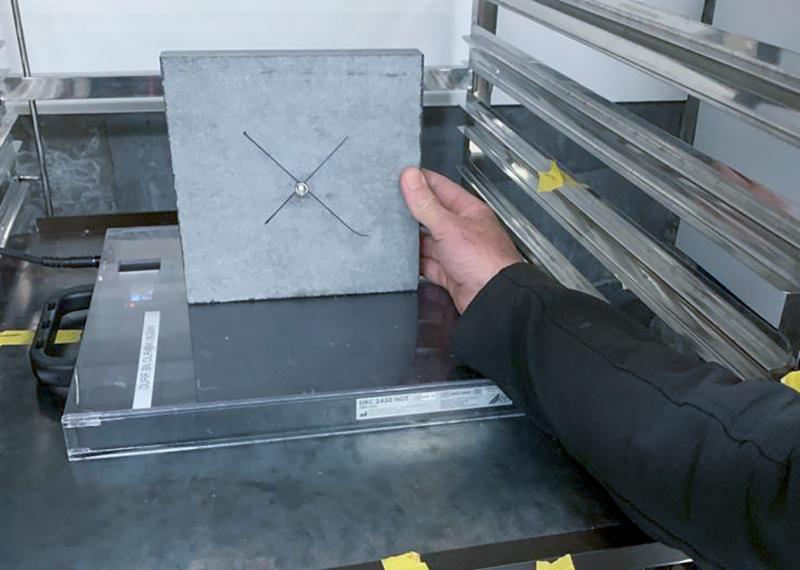

For this particular application, after the imaging plates are exposed offshore using an Iridium-192 isotope source, they are brought back to the MESB main office where they are scanned by the HD-CR 35 NDT and then interpreted by one of several operators trained to use the system. MESB uses DÜRR NDT’s high sensitivity white imaging plates (CR-IP) and encourages proper handling practices among its team members: “In the three years we have used this CR system, not one single imaging plate has been damaged. One of the main reasons is that we encourage the use of single-use envelopes in order to protect the imaging plates. Furthermore, each member of our 5-person radiography testing crew is only issued with a certain amount of imaging plates which they cannot swap and are then their responsibility to take care of. By doing this we are able to use each imaging plate more than 1000 times”, explains B.C. Mohan, Contract Manager at MESB.

MESB also relies on the automatic wall thickness measurement tool in the DÜRR NDT D-Tect software to perform their pipeline corrosion monitoring tasks. After performing an internal study using ultrasonic methods as a reference, MESB found that the wall thickness measurements produced by the D-Tect automated software tool matched closely to the reference thickness values (< 5 % difference) – thus giving operators the confidence to make correct evaluations. According to B.C. Mohan, “automated analysis increases the reliability of wall thickness measurement which allows fit-for-purpose (FFP) assessments to be conducted more accurately”.

Previously, a large issue MESB experienced was the amount of time required for reshoots – with conventional radiography they found that at least 15 to 20 % of images needed to be reshot due to poor image quality or under/over-exposure. After the introduction of the HD-CR 35 NDT, the number of reshoots required dropped to less than 1 %. “Since the HD-CR 35 NDT has enormously decreased reshoots, computed radiography has become widely accepted by the Brunei oil and gas industry for on-stream inspections at offshore facilities”, commented B.C. Mohan.

Due to the high demand for radiographic inspection of pipelines in the region, the HD-CR 35 NDT investment payback period for MESB was only one year. MESB is also fully supported by Singapore-based NDT Instruments Pte Ltd who performs annual maintenance and any other required service activities ensuring the system has minimal downtime.

www.duerr-ndt.com

DÜRR NDT is a German manufacturer of digital imaging systems for NDT – radiographic testing, such as CR imaging plate scanner, flat panel detectors, dda, imaging software, automatic X-ray film processor, „green“ X-ray chemicals.

DÜRR NDT GmbH & Co. KG

Höpfigheimer Straße 22

74321 Bietigheim-Bissingen

Germany

Tel. +49 7142 99381-0

info@duerr-ndt.com

www.duerr-ndt.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Enabling Safe and Efficient On-Stream Pipeline Inspection with Computed Radiography here

News-ID: 919525 • Views: …

More Releases from DÜRR NDT GmbH & Co. KG

DÜRR NDT's HD-CR 35 NDT Supports Bringing Astranis Satellites Into Orbit

Astranis is building small, low-cost telecommunications satellites to connect the four billion people on Earth who currently do not have access to the internet. The company is headquartered in San Francisco and has raised over $ 500 million from top global investors, with a team of over 300 world-class engineers. Founded in 2015 with an audacious mission: to connect the world by reducing the cost of internet services in rural and…

The Mariners' Museum and Park Explores Maritime History Using Digital X-ray Imag …

The Mariners' Museum and Park in Newport News, VA, USA, is home to the Batten Conservation Complex and the USS Monitor Center.

Within the Batten Conservation Complex, conservators specializing in archival documents, paper, objects, and archaeological materials work alongside a research scientist to stabilize and preserve the collection for generations to come. Researchers across the team continue to build the body of knowledge gleaned from the collection, uncovering the full stories…

DÜRR NDT Supports Digital Radiography Training in Australia

ATTAR (Advanced Technology Testing and Research), headquartered in Victoria, Australia with a team of around 45 employees provides a range of services such as non-destructive testing, failure analysis and forensic engineering, risk assessment services, and specialist testing of structures and vessels. ATTAR also provides year-wide training courses for all major NDT techniques such as radiography, ultrasonic, magnetic particle, and eddy current testing.

ATTAR has been using DÜRR NDT computed radiography scanners…

Seamless Digital RT Workflow with DRIVE NDT and D-Tect X from DÜRR NDT

For an optimal digital workflow in radiographic testing (RT), the X-ray inspection software D-Tect X can be integrated with the NDT management software DRIVE NDT. The closely meshed interaction between DRIVE NDT and D-Tect X means that a large part of the process takes place automatically. This not only saves time, but the automatic exchange of data also minimizes the possibility of human error. As all the steps and processes…