Press release

Particle monitors for explosive atmospheres

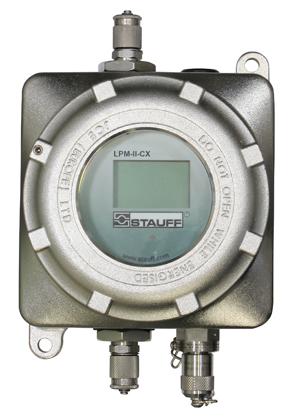

The robust housing hermetically shields the internal electronics of the particle measuring device from explosive atmospheres

The special feature: The new version is equipped with a large-area front display which allows users to read out measured values in real time. This enables the machine operator or the responsible maintenance personnel to directly react to increasing contamination of the fluid, to reduce system downtimes and to protect the system against expensive malfunctions.

Particle monitors from the LPM-II series – whether with or without ATEX2 approval – allow continuous determination and classification of the degree of contamination in synthetic and mineral oil based fluids, diesel and petroleum in 8 size channels between 4 μm(c) and 70 μm(c) as per ISO 4406:1999 and other international standards. Devices which are compatible with special water glycols, phosphate testers (e.g. Skydrol®) and other aggressive media are optionally available, as well as integrated water-in-oil and temperature sensors.

In addition to the robust housing design, which hermetically shields the internal electronics from explosive atmospheres, the LPM-II-CX features a large integrated data memory for up to 4,000 standard measurements and the option of connecting it to existing machine systems using the Modbus and CAN bus interfaces included in the devices as a standard.

About the STAUFF Group

For more than 50 years, the companies of STAUFF Group, since April 2015 also including VOSWINKEL, have been developing, manufacturing and distributing pipework equipment and hydraulic components for mechanical and plant engineering and for service and industrial maintenance.

The overall range currently includes about 40000 standard components in ten product groups as well as a large number of special and system solutions, which are manufactured to customer specifications or based on in-house developments.

Wholly owned manufacturing, sales and service facilities in 18 countries and a tight global network of authorised distribution partners ensure high presence and service paired with a maximum of availability.

With around 1350 employees worldwide, including 550 at five sites in Germany, the companies of STAUFF Group achieved external sales of over EUR 210 million in the business year 2016.

www.stauff.com

Press Contact

Walter Stauffenberg GmbH & Co. KG

Mr Boris Mette

Im Ehrenfeld 4

58791 Werdohl

Phone: +49 (0) 2392 / 916-154

Telefax: +49 (0) 2392 / 916-270154

eMail: b.mette@stauff.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Particle monitors for explosive atmospheres here

News-ID: 807735 • Views: …

More Releases for STAUFF

Voswinkel becomes part of the Stauff Group

(Meinerzhagen / Werdohl, Germany) As mutually announced by both companies, the Stauff Group has successfully completed the acquisition of the Meinerzhagen, Germany based company Voswinkel from the Voswinkel shareholder family in April this year already.

With corporate headquarters in Werdohl, Germany and two additional plants in Plettenberg-Ohle and Neuenrade-Küntrop, the Stauff Group develops, manufactures and distributes pipework equipment and hydraulic components for mechanical and plant construction as well as for…

Updated Stauff One product catalogue available

Updated Stauff One product catalogue available

Pipework components, test equipment and hydraulic accessories from a single source

Beginning in February 2014, the new, revised and in some areas significantly expanded general product catalogue will be available from Stauff, the Werdohl, Germany based fluid technology specialist.

On a total of 682 pages, the so-called Stauff One – initially released in spring 2011 – provides all relevant general, ordering and technical information about the company’s…

STAUFF trainee achieves best grade

Florian Kircher, previously trainee for the position of cutting mechanic with the subject area of automatic lathe systems at the Werdohl production plant of Walter Stauffenberg GmbH & Co. KG, has been named one of the best graduates in his training class. At a celebratory ceremony on 16 October, Mr Kircher, who this year completed his vocational training before the testing committees of the South Westphalian Chamber of Industry and…

Withstanding Extreme Conditions - Stauff Clamps meet the requirements of Russian …

The Stauff Group have been suppliers to the rail industry for almost 35 years, the first project starting in the 1970s with Stauff UK supplying clamping components and systems to the Metropolitan Cammell Carriage and Wagon Company (MCCW), a former Birmingham, England based manufacturer of railway carriages and wagons. Original STAUFF clamps were used for trains on the Jubilee Line of London's underground railway system, which was officially opened on…

Stauff clamps assure safe installation of hydraulic hoses

Stauff provides a range of products that assures your hydraulic system operates safely and in a secure environment for components. Stauff clamps are applied to many industrial hydraulic applications and although the standard ribbed option is prominent in fixed-pipe systems, the use of the PPH smooth bore range offers unique advantages to the safe clamping and supporting of hydraulic hose. Hose is an integral component in a hydraulic system…

Bring on the water: Stauff industrial filters

For the first time, the German fluid power specialist Stauff will be presenting an independently developed solution for the filtration of industrial water at the Hanover trade fair in April 2013. The SRFL-SW single filter housings have been designed to be used in the steel industry for pre-filtering or coarse filtering in descaling plants.

The SRFL-SW series was developed and designed for direct installation into the pipelines of industrial water…