Press release

Green Cleaning Solutions from Schwing Technologies for the South American market

Neukirchen-Vluyn (Germany), 19.10.2017. Virgilio Perez Guembe has just come back from South America. His itinerary took him to Colombia, Ecuador and Mexico. In places where other people spend their vacation, the thermal cleaning expert from SCHWING Technologies had to attend consultations and meetings with customers. Just like Colombia’s tourist office which welcomes visitors at the airport with the image of a green natural paradise, the South American plastics industry also focuses on environmental issues and reducing emissions. Green solutions are becoming more and more important in many production processes and applications in the plastics processing industry. This applies to extrusion production and injection molding as well as the recycling industry. German equipment manufacturer SCHWING offers environmentally friendly and energy efficient cleaning systems for these and other manufacturing sectors. Guaranteed not to contain any added chemical substances or the use of TEG (triethylene glycol).“Our intelligent systems remove all polymers from tools and machine parts of any type and size,” explains Perez Guembe, cleaning expert from SCHWING, “they are extremely reliable and thorough.” At its production site in Mexico, the world’s largest toy manufacturer was suitably impressed, to name but one example. The Danish toy giant has been using the German fluidized bed system to clean its injection molding tools all over the world for many years. At the production site in Cienega de Flores, near Monterrey, an INNOVACLEAN system from SCHWING ensures that machine parts are thoroughly cleaned. This saves time and money and improves the quality of toy brick production in Mexico. Due to the sharp increase in the number of production lines, the company is already thinking about a second system.

“However, other companies are completely unaware of these professional thermal cleaning solutions,” as Perez Guembe was able to observe during his trip. Cleaning is often still done manually over there. Even hot runners. The cleaning expert has made it his mission to promote the attractive economical and eco-friendly alternatives available.

Thanks to its green cleaning solutions, the German system manufacturer has become a highly successful international specialist for polymer removal. Made in Germany - since 1969. The expert offers intelligent, reliable systems for all industries, i.e. food packaging, medical technology and automotive manufacturing.

SCHWING customers profit from fast and reliable cleaning of tools and components, which can be used more than once and lead to longer cleaning intervals. Thanks to excellent cleaning results, our customers are able to produce more better quality products for the same cost,” says Perez Guembe. Quality plays an important role. Tools and machine parts must always be completely and thoroughly cleaned, so that carbon residues to which new polymers could otherwise adhere, are completely removed. “There are no tolerances allowed. Poor quality means delays in the process chain and possible future complaints. This must not happen and we will remedy this situation,” confirms the expert.

The German system manufacturer provides the plastics manufacturing industry with three different green cleaning solutions. They all have one thing in common, they remove all polymers in a reliable and environmentally-friendly way without any residue. Quickly and without waste.

Extrusion machine parts, for example, are easily cleaned with the gentle VACUCLEAN vacuum pyrolysis system. At the end of the cleaning process, pelletizing nozzles and heads, filter bundles and discs, film extrusion dies, extruder screws and spinnerets, meltblown or spundbond dies almost look as new.

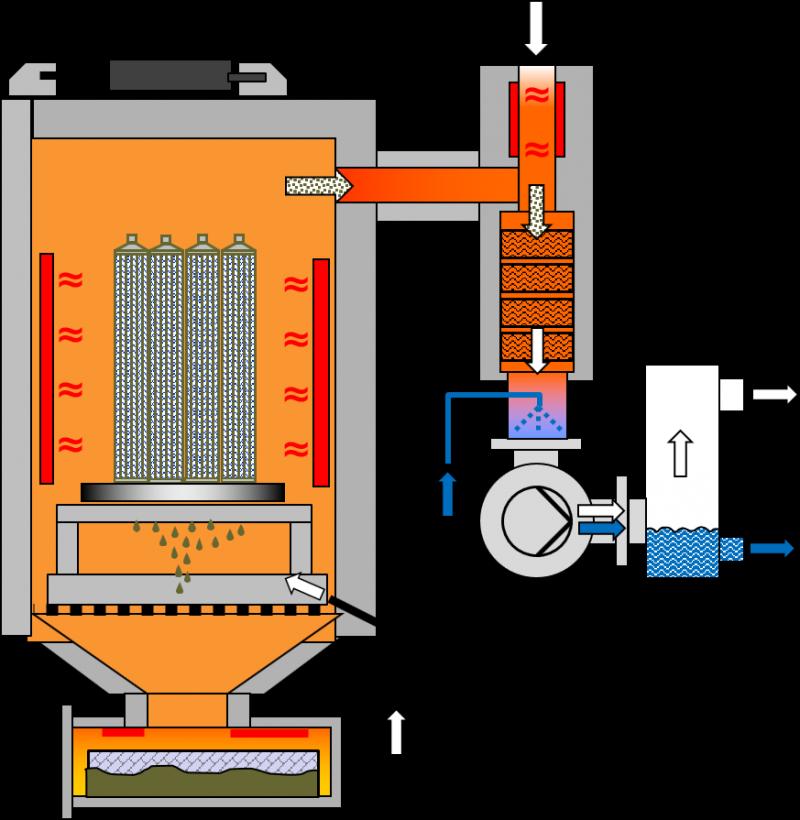

INNOVACLEAN is the name of the fluidized bed system, aimed primarily at the injection molding industry. This technology is ideally suited for all polymers, including high temperature polymers such as LCP, PEI, PPS, PI and even PVC and halogenated polymers such as PTFE. The system is especially recommended for cleaning die plates, screw elements, special profile die, hot runner distributors, spinnerets and assembled spin packs.

Large tools and components, such as heat exchangers, extruder screws, large extruder tools, pelletizing dies or large hot runner tools can be thoroughly cleaned in the gas-heated MAXICLEAN pyrolysis oven. SCHWING also offers complete cleaning services: from dismantling to thermal cleaning to after-treatment and inspection.

Further informationen: www.schwing-technologies.com

SCHWING Technologies

Schwing Technologies has been operating since 1969 and is the worldwide technological leader for high-temperature systems for thermal cleaning, thermo-chemical finishing and heat treatment of metal parts and tools. The owner-managed company constructs, manufactures and operates its systems at its headquarters in Neukirchen-Vluyn in Germany's Lower Rhine region. Built upon the achievements of German engineering, the medium-sized business is globally the best-known specialist in the removal of plastics. Among its around 2,500 international clients are companies from the plastics and fiber industries, as well as from the chemicals, metals and automobile sectors. With its 80-strong personnel, the company is equipped with the tools and systems for any cleaning need and delivers the best economy, ecology and quality. Schwing is also a reliable service partner for contract cleaning by cleaning more than 100,000 tools and parts each year to the highest environmental and qualitative standards. In the words of Ewald and Thomas Schwing, the two managing directors at Schwing Technologies GmbH, “So far, there has not been a single component that we have not been able to free from polymers and inorganic contaminants.”

Press contact:

Nicola Leffelsend

SCHWING Technologies GmbH

Oderstrasse 7

47506 Neukirchen-Vluyn

Germany

Phone +49 2845 930 146

redaktion@schwing-tech.com

www.schwing-technologies.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Green Cleaning Solutions from Schwing Technologies for the South American market here

News-ID: 779864 • Views: …

More Releases from SCHWING Technologies GmbH

New at the trade fair K 2019: SCHWING Technologies cleans tall filter candles up …

Neukirchen-Vluyn (Germany), October 8, 2019. At this year's K 2019 in Düsseldorf from October 16 to 23, SCHWING Technologies will be presenting its extended vacuum pyrolysis system VACUCLEAN 0917 for the first time (Hall 9/booth A77). With this system, the German expert for environmentally friendly and energy-efficient thermal cleaning systems is primarily targeting users of especially tall filter candles and bundles up to 170 cm high and 0.90 cm in…

SCHWING Technologies: thermal cleaning of filter bundles for the packaging indus …

Neukirchen-Vluyn (Germany), September 4, 2019. The cleanliness of filter bundles and filter candles is essential when it comes to quality of the film. The packaging industry used to replace these filters, but today, they are often cleaned for reuse. Why? Depending on the degree of filtration, investments of roughly 600 Euro per filter candle are not uncommon. Cleaning in a VACUCLEAN vacuum pyrolysis system and other post-treatment equipment for reuse,…

ITMA 2019: Predictive maintenance secures production processes in the fiber indu …

Neukirchen-Vluyn (Germany), May 2, 2019. The production of textiles and clothing will be the focus of this year's ITMA 2019 in Barcelona. From June 20 to 26, 2019, the German specialist SCHWING Technologies will be presenting thermal cleaning solutions for polymer-contaminated production tools. In hall 7 / booth C120, SCHWING experts, Managing Director Thomas Schwing and Head of Sales Virgilio Perez Guembe, will inform about the potentials and advantages of…

More Releases for German

Find the best conditions for your German mortgage with Your German Mortgage

During times of the Coronavirus, we are here to help you with finding the right financing for your property.

Special times call for special measures, that's why it's now more important to find a trustworthy and experienced mortgage broker than ever.

We got you covered from finding your property of dreams all the way to financing it.

To ensure that, we have experts in almost every German major city,…

German Maritime Security 2018, German Government Statement!

Despite all international and national efforts, piracy remains a serious peril for the international shipping industry.

Especially in Asia (i.e. Chittagong/Bangladesh or on the Strait of Malacca), but also in South America (e.g. Bay of Santos/Brazil or in the port of Callao/Peru) robbery or piracy there has recurred in the recent past. At the West African coast the number of incidents had raised even by 50% with 66 incidents this…

More German Investments Mean More German Translations

Why Language Continues to be an Obstacle for Investing in Germany

Germany is one of the prime markets for foreign investments, with an estimated 4% of global direct investment making its way into the country. In fact, the world’s second richest man, Warren Buffett, who is only beaten to the top spot on the financial leaderboard by Microsoft Founder Bill Gates, believes Germany to be a ‘great market’, and confirms the…

German Design Award 2015

German Design Council Awards a Special Mention to the LR 1000 Laboratory Reactor and Nominates the Tube Mill

Staufen, Germany, February 23, 2015 —

For the second time, a device produced by IKA® Werke has received the "Special mention for exceptional design quality" award from the German Design Council.

The company was presented with the award in the "Excellent Product Design — Industry" category as part of the German Design Award 2015…

German Local Trade Tax

All the companies in Germany are liable to pay not only corporate income tax, whose rate is nowadays about 15% of the annual profit of the company, but also trade tax (Gewerbesteuer), which is a tax of German characteristics.

Why would we say that trade tax is of German characteristics? Because it is different from the corporate income tax, which is charged by the German Federal Government and it is difficult…

ISPA – German Masters 2008

Magdeburg – Over the long weekend of the 4. Mai more than 1.000 Skat players filled the Mittelland hall in Barleben. The tournaments of the 30. German Mastery and the 27. open International German Single Mastership were held by the International Skat Players Association, ISPA Germany. Patrons of the Games were the 1st Barleber Skat sports club e.V. and the Skat club \"Burger Ihleskater\", whose good organization together with the…