Press release

Smart sensors for efficient processes

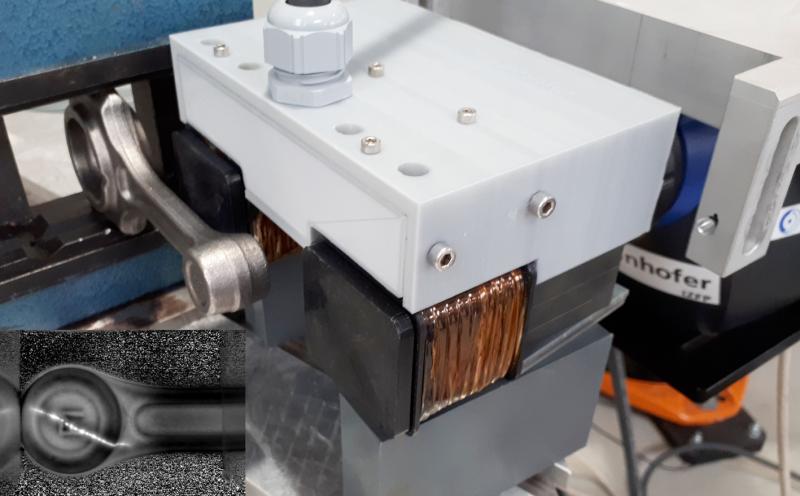

An engineer performs robotics-supported testing of steel sheets for mechanical properties (residual stresses).

When quality testing uses time-consuming destructive test methods, it can result in enormous costs due to damaging or destroying the products. And given that testing is restricted to random sampling, faults in processes are often not found until a large amount of scrap has already been produced. Consequently, nondestructive testing method represent an alternative, and after appropriate adaptation processes, also a replacement for destructive methods for the long run.

Cognitive sensors for quality assurance in production

At this year's Blechexpo, our engineers will demonstrate a robotics-supported sensor system that can rapidly and easily be integrated into production processes. The automated application of intelligent, nondestructive sensor systems is not only essential for ensuring optimum product quality in production, it is also indispensable for realizing current machine learning concepts. The potential use of such systems will be demonstrated in an exemplary case of robotics-supported testing of press-hardened parts by means of EMAT* and 3MA**. EMAT allows couplant-free testing of defects in sheet metal, while parallel application of 3MA makes quantitative material characterization possible.

Testing within seconds

The advantages of the robotics-based combination of the two sensors (3MA, EMAT) include rapid testing in mere seconds, determining and evaluating several relevant quality characteristics, as well as the nondestructive testing of sheet metal. "The combined sensor-based testing process allows early detection of mechanical properties, e.g., the residual stress and the hardness of steel, as well as defects like cracks or necking. This will save resources, reduce costs, and contribute to strengthening manufacturers' competitive position," explained Frank Leinenbach, development engineer at the Fraunhofer IZFP. The institute has decades of experience and expertise in combining and automating nondestructive testing methods for production.

Quality assurance during steel production

The steel-producing and -processing industries need nondestructive testing methods in quality assurance. Frequently relevant quality characteristics include hardness, case depth, strength, and residual stresses. In this context, nondestructive micromagnetic testing methods are optimally suited for providing fast and reliable statements on the quality status of ferromagnetic materials. "An inspection task that is being requested frequently is the monitoring of heavy steel plates, and the related detection of localized increases in surface hardening," explained Sargon Youssef, researcher and engineer at the Fraunhofer IZFP. These localized effects can be detected by means of micromagnetic measuring effects when the 3MA-X8 testing technology developed at the Fraunhofer IZFP is applied. The specific strengths of the 3MA-X8 testing system lie in its user-friendly learning curve and calibration, as well as in its variable and robust sensor design. A key point is the test system's multi-channel real-time capability.

The 3MA-X8 testing method will be demonstrated at the Blechexpo in Stuttgart using a fair exhibit. As under realistic conditions, our high-tech testing technology will be integrated in a miniaturized rolling line. Here, sheet metal to be tested will be measured using the testing method, detected, and sorted – if necessary – into "OK sheet metal" or "not-OK sheet metal".

* EMAT: Electromagnetic acoustic transducer

** 3MA: Micromagnetic multiparameter, microstructure, and stress analysis

www.izfp.fraunhofer.de

As an internationally renowned R&D center for nondestructive testing methods (NDT) Fraunhofer IZFP does research and development work for nondestructive monitoring in the field of materials, component, and product characterization. The institute develops industrial-grade high-performance system solutions to prototype and series maturity, covering the entire range of nondestructive inspection methods aligned to industry-specific product life cycles, from which we derive the current challenges our customers and partners face. The institute’s scientists, engineers, and technicians compile application-oriented monitoring solutions to enhance the quality of our customers’ products, starting with process-integrated sensors up to Materials Data Space applications.

Dipl.-Übers. Sabine Poitevin-Burbes

Fraunhofer Institute for Nondestructive Testing IZFP

Head of Corporate Communications

Campus E3 1, 66123 Saarbrücken, Germany

Phone +49 681 9302-3869 I Fax +49 681 9302-113869

sabine.poitevin-burbes@izfp.fraunhofer.de I www.izfp.fraunhofer.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Smart sensors for efficient processes here

News-ID: 777225 • Views: …

More Releases from Fraunhofer IZFP

Under scrutiny: Automated induction thermography for surface crack testing of fo …

Within the framework of a project funded by the "Arbeitsgemeinschaft industrieller Forschungsvereinigungen" AiF ("Consortium of Industrial Research Associations"), Fraunhofer IZFP scientists investigate the reliability of the automated application of the thermographic crack detection method: After positive validation, this technology is to find better acceptance as an alternative to the established magnetic particle inspection. Using this method, surface-related defects such as cracks in forged parts can be determined quickly, objectively and…

Fraunhofer IZFP at GIFA 2019: Robot-assisted sensor system for the quality monit …

Within the framework of quality monitoring of lightweight construction components intelligent sensor systems become crucial: In many industries, especially in aerospace engineering and automotive industry, the use of forward-looking hybrid designs based on fiber composites and light metals is steadily rising. Material defects in the final product may result in early malfunction, thus, impairing the safe use of the product. From 25-29 June 2019, at the 14th International Foundry Trade…

More Releases for EMAT

Electromagneti Acoustic Transducer (EMAT) Market Size 2022: Applus, Olympus, Inn …

Electromagneti Acoustic Transducer (EMAT) Market research report studies the competitive development of the market, such as agreements, new product launches, expansions, and acquisitions in the market. In addition, it provides a region-wise study of the market, including North America, Asia Pacific, Latin America, the Middle East, Africa, and Europe. As a result, it helps stakeholders understand market players and analyze the top 25 organizations based on their product footprint, market…

Electromagneti Acoustic Transducer (EMAT) Market 2022- Global Key Players, Trend …

The report named, *Global Electromagneti Acoustic Transducer (EMAT) Market Research Report 2022* has been added to the archive of market research studies by QY Research. The industry experts and researchers have offered a reliable and precise analysis of the global Electromagneti Acoustic Transducer (EMAT) market in view of numerous aspects such as growth factors, challenges, limitations, developments, trends, growth opportunities, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and…

Ultrasonic Monitoring Equipment 2017 Global Market Growth, Opportunities and Ana …

Global Ultrasonic Monitoring Equipment Market

This report mainly introduces volume and value market share by players, by regions, by product type, by consumers and also their price change details. As a Detailed Analysis report, it covers all details inside analysis and opinion in Ultrasonic Monitoring Equipment industry.

This report splits Ultrasonic Monitoring Equipment market By Method, By Product & Service, which covers the history data information from 2012 to 2016 and forecast…

Global Ultrasonic Monitoring Equipment Market: Japan Industry Analysis, Size, Sh …

Researchmoz added Most up-to-date research on "Global Ultrasonic Monitoring Equipment Market: Japan Industry Analysis, Size, Share, Volume, Growth, Trends, and Forecast, 2017 - 2022" to its huge collection of research reports.

The global Ultrasonic Monitoring Equipment market is valued at XX million USD in 2016 and is expected to reach XX million USD by the end of 2017, growing at a CAGR of XX% between 2016 and 2022.

Japan plays an important…

Latest Research Report on Global and United States Ultrasonic Monitoring Equipme …

Researchmoz added Most up-to-date research on "Global and United States Ultrasonic Monitoring Equipment In-Depth Research Report 2017-2022" to its huge collection of research reports.

The report is based on the market historical data from 2012 to 2016 and forecast the market trend from 2017 to 2022.

This report focuses on the U.S. market and presents volume and value of market share by players, by regions, by product type, by consumers and also…

Ultrasonic Monitoring Equipment Worldwide Detail Industrial and Market studies R …

"Global Ultrasonic Monitoring Equipment Market Research Report 2017-2022 by Players, Regions, Product Types & Applications" The Report covers current Industries Trends, Worldwide Analysis, Global Forecast, Review, Share, Size, Growth, Effect.

Description-

The global Ultrasonic Monitoring Equipment market is valued at XX million USD in 2016 and is expected to reach XX million USD by the end of 2022, growing at a CAGR of XX% between 2016 and 2022.

This report offers an overview…