Press release

SABIC Innovative Plastics’ High-Performance Materials Help Domestic Boiler Manufacturers Warm Up Homes, Not the Planet

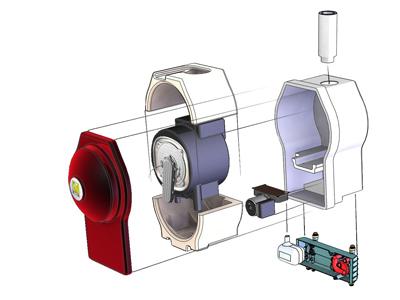

Conceptual Boiler Showing Possibilities for Metal Replacement in Components such as Manifolds, Condenser Housings and Enclosure Components

“Although wall-hung domestic boilers have been widely used in Europe for years, accelerating efforts to reduce global warming and cut fuel costs are driving more global use of high-efficiency condensing models,” said Gunes Celik, SABIC Innovative Plastics’ new business development manager in Europe. “SABIC Innovative Plastics is deeply involved in developing new materials for our customers to enhance the performance, longevity and fuel efficiency of heating boilers. Through our research and testing, we offer customers the latest material solutions for designing next-generation products that can efficiently heat homes without overheating the planet.”

New Resins Outperform Traditional Metals in Boiler Design and Operation

SABIC Innovative Plastics has developed the new resins to provide many advantages over existing metals. For high-efficiency condensing boilers, which are growing annually by 10 percent in Europe, Noryl PPX resin offers a better choice than stainless steel for condenser housings. As wall-hung boilers become more efficient, the temperature requirement for the housings drops, while chemical resistance becomes more important (due to condensation of exhaust fumes). With greater exposure to chemicals, metal corrodes. Noryl PPX resin provides exceptional chemical resistance for longer part life, as well as the ability to withstand the required heat from the condenser.

Other candidates for metal replacement are boiler manifolds, which have historically been made of copper tubing and brass parts. Using metal is labor-intensive, complex and expensive. Further, brass contains lead, which is being increasingly discouraged by authorities and is already restricted in California, U.S.A. By upgrading to Noryl glass-filled resin or Ultem resin – SABIC Innovative Plastics materials for highly demanding designs – manufacturers may be able to consolidate parts, create new products more easily, reduce weight, and save on fabrication and assembly costs.

A third application area is the boiler control panel cover and enclosure components, typically made of painted sheet metal. SABIC Innovative Plastics’ flame-retardant Cycoloy resins offer excellent aesthetics and surface finishes combined with high-flow properties to mold thin-wall parts. With Cycoloy resins, manufacturers can achieve attractive covers and comply with flame retardancy requirements without the secondary operations required for metal, as well as reducing the overall weight of the boiler.

Compliance with New Regulations

National health institutes worldwide specify requirements of polymers in potable water. For instance in Germany, Kunststoffe im Trinkwasser (KTW) and the German Technical and Scientific Association for Gas and Water (DVGW) recently upgraded regulations that influence plastics selection in hot water, such as for microbiological growth (W270). Both Noryl and Ultem resin grades from SABIC innovative Plastics possess an extensive listing for tests like these.

For additional information on SABIC Innovative Plastics’ resins for fluid handling applications, please go to www.sabic-ip.com.

About SABIC Innovative Plastics

SABIC Innovative Plastics is a leading, global supplier of engineering thermoplastics with a 75-year history of breakthrough solutions that solve its customers’ most pressing challenges. Today, SABIC Innovative Plastics is a multi-billion-dollar company with operations in more than 25 countries and over 9,500 employees worldwide. The company continues to lead the plastics industry with customer collaboration and continued investments in new polymer technologies, global application development, process technologies, and environmentally responsible solutions that serve diverse markets such as automotive, electronics, building & construction, transportation, and healthcare. The company’s extensive product portfolio includes thermoplastic resins, coatings, specialty compounds, film, and sheet. SABIC Innovative Plastics (www.sabic-ip.com) is a wholly owned subsidiary of Saudi Basic Industries Corporation (SABIC), one of the world’s top five petrochemicals manufacturers.

# # #

* Trademarks of SABIC Innovative Plastics IP BV.

Kevin Noels

Marketing Solutions, Bergen op Zoom,

The Netherlands

Tel: +31 164 317 011

E-Mail: knoels@marketingsolutions.be

www.pressreleasefinder.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release SABIC Innovative Plastics’ High-Performance Materials Help Domestic Boiler Manufacturers Warm Up Homes, Not the Planet here

News-ID: 76874 • Views: …

More Releases from SABIC Innovative Plastics

SABIC Launches Portfolio of Antimicrobial Compounds at MD&M West to Help Custome …

According to a 2011 report by the World Health Organization, in 2002 in the United States alone approximately 99,000 deaths were linked to healthcare associated infections (HCAIs).1 Here at MD&M West (booth #1701), SABIC’s Innovative Plastics business today introduced powerful new tools to help medical device manufacturers reduce HCAIs among patients and clinicians. SABIC’s nine new antimicrobial compounds featuring silver technology have been tested for log reduction values – the…

SABIC’s 3D-Formed LEXAN™ Sheet Increases Visibility, Safety, Comfort and Per …

Operators of logging equipment require exceptional visibility and protection against debris or large objects that may enter their cabin and cause serious injury in forest environments, such as tree limbs and other machinery parts. So when Rottne Industry AB needed a high-performance glazing material for the windshields and windows of its harvesters and forwarders, it turned to

SABIC’s Innovative Plastics business for support. Working with SABIC and its distributer, Vink…

Mitsubishi Motors Corporation Selects SABIC NORYL GTX™ Resin for 2013 Outlande …

SABIC’s Innovative Plastics business today announced that Mitsubishi Motors Corporation (MMC) has chosen SABIC’s next-generation NORYL GTX™ 989 resin for the front fenders of its 2013 Outlander Sport crossover. The vehicle’s fenders are the first to be produced using 2-cavity injection molding with NORYL GTX resin, allowing MMC to cut cycle times in half and reduce tooling costs. Other major benefits of the SABIC material include weight savings vs. steel…

SABIC Makes a Splash at Fakuma with New NORYL™ Resin, Meeting Tightening Globa …

Here at the Fakuma trade fair, booth #B5-5506, SABIC’s Innovative Plastics business today announced a new NORYL™ resin that not only complies with current European and global sustainability regulations governing materials used in potable water systems, but also with new, tougher regulations slated to go into effect in 2016. Developed at SABIC’s Fluid Engineering Center of Excellence in the Netherlands, NORYL FE1630PW resin is a 30-percent glass-reinforced polyphenylene ether (PPE)…

More Releases for Components

Disel Exhaust Fluid Components (DEF) Components Market Outlook: Growth, Challeng …

DataM Intelligence has published a new research report on "Disel Exhaust Fluid Components Market Size 2025". The report explores comprehensive and insightful Information about various key factors like Regional Growth, Segmentation, CAGR, Business Revenue Status of Top Key Players and Drivers. The purpose of this report is to provide a telescopic view of the current market size by value and volume, opportunities, and development status.

Get a Free Sample PDF Of…

Train And Components Market Report 2024 - Train And Components Market Growth And …

"The Business Research Company recently released a comprehensive report on the Global Train And Components Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

Ready to Dive into Something Exciting? Get Your Free Exclusive…

PC Components Market High-Performance Components for Personal Computers and IT S …

Global PC Components Market Overview:

The PC Components market is a broad category that includes a wide range of products and services related to various industries. This market comprises companies that operate in areas such as consumer goods, technology, healthcare, and finance, among others.

In recent years, the PC Components market has experienced significant growth, driven by factors such as increasing consumer demand, technological advancements, and globalization. This growth has created both…

Rubber Molding for Automotive Components and Sub-Components Market 2022 | Detail …

Global Rubber Molding for Automotive Components and Sub-Components Market 2022-2028, has been prepared based on an in-depth market analysis with inputs from industry experts. The report covers the market landscape and its growth prospects in the coming years. The report includes a discussion of the key vendors operating in this market. An exclusive data offered in this report is collected by research and industry experts team.

Download FREE Sample Report @…

Rubber Molding For Automotive Components and Sub Components Market Is Thriving W …

Rubber Molding for Automotive Components & Sub-Components Market: Introduction

The process of rubber molding involves shaping rubber material into functional products in the automotive ancillary components industry. Products that are made through rubber molding are enclosed in a mold cavity instead of a die which can be made into complex as well as required shapes.

Some of the areas where rubber molded components are used in automotive are brakes, transmissions, steering, engines,…

Active Electronic Components Market - Miniaturized Electronic Components Are Als …

Electronic components can be broadly categorized into electromechanical components, active electronic components, and passive electronic components. The active electronic components refer to display device, semiconductor devices, and others. Various semiconductor devices include transistors, integrated circuits diodes, and optoelectronic components. In 2014, semiconductor devices held approximately 50% of the global active electronic components market. Reduction in component size and reliability boosted the growth of the market. This has propelled the usage…