Press release

Guyson to Release Details of Powder Recovery System at TCT 2017

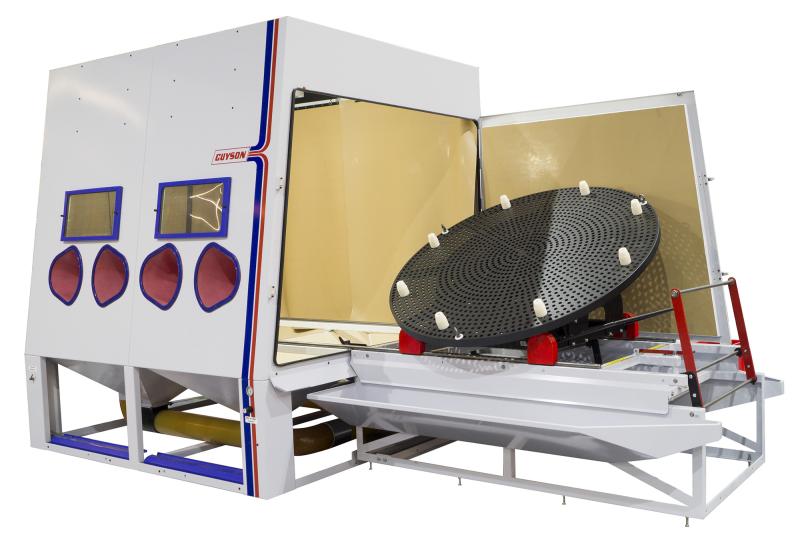

Guyson Euroblast 6 ‘AM’ Finishing Station with optional micro tipped Pencil Blaster and the Guyson C600 Dust Collector

Mark Viner, Managing Director of Guyson’s Blast & Wash Division, says “Users of powder based additive manufacturing systems are encouraged to come onto the Guyson stand to have constructive conversations about the benefits our latest robotically controlled finishing station and powder recovery system will bring to the user and discuss the time and financial savings to be made and the operational safety benefits over current manual operations. This exciting new development for the AM sector incorporates the best of Guyson’s long standing automated robotic blasting technology coupled with Guyson’s technology partner Russell Finex’s sieving and screening expertise”.

Guyson will also be exhibiting entry and mid-level manual finishing stations and complementary dust collection options which incorporate numerous safety features, beyond most competitors, enabling the operator to surface finish almost any material safely.

Guyson’s entry level finishing station for 3D Printed components is the Guyson Formula 1400 ‘AM’ version which will also feature a Pencil Blast unit with micro tipped blast nozzle for intricate detailed surface finishing. The 1400 ‘AM’ unit forms part of the Guyson Formula blast range which offers three cabinet sizes; including a bench-top version and is ideal for smoothing out striation lines, finishing SLS prototypes or creating the perfect keyed surface for painting on FDM 3D printed components.

Also showing will be a Guyson Euroblast® 6 ’AM’ finishing station which has been devised especially for the additive manufacturing (AM) market. These particular ‘AM’ finishing stations are designed specifically for surface finishing Stainless, Aluminium, Titanium or Inconel built components, which are often used in aerospace and medical sector. Some of these exotic materials have the potential to create explosive dust when blasted, so special provision is made with these Guyson blast systems to mitigate those risks.

The Guyson ‘AM blast systems’ come complete with full earth braiding to the cabinet, gun, dust collector and hose and include ground nuts on all the main contact points to prevent any static spark generation and also anti-static fabric gauntlets to allows the operator greater flexibility when blasting whilst preventing media escape. Also externally located LED lighting, for good illumination of the blast area and to remove any chance of a spark within the blast chamber.

The Guyson AM blast cabinets are complemented with the new range of AM specified dust collectors, Guyson will be exhibiting the mid-range C600-AM dust collector designed to accompany the Euroblast 6SF–AM also on show. Again conscious of the explosive potential of some of the materials that can be involved in additive manufacturing the C600-AM dust collector has a host of features and options to minimise risks including; explosion relief valve, explosion isolation valve, secondary HEPA filtration, waste bin balance pipe - this enables dust collection in a plastic bag (located in the collection bin hopper) that can be quickly sealed on removal, minimising dust in the open atmosphere and a waste bin level sensor. Further, flexible extraction arm options, allows the C600-AM dust collector to be used in conjunction with powder filling and breakout station activities. Depending on the specific zone or environment, the AM dust collector can be specified with fully ATEX compliant motor, controls and switchgear.

Manning the stand will be a number of Guyson sales engineers able to answer visitors’ technical queries on the equipment or on application usage. Prospective users of Guyson finishing stations or powder recovery systems are also encouraged to submit sample components for free feasibility testing to the company’s extensive ‘Component Finishing Centre’ in Skipton, North Yorkshire.

About Guyson

Guyson International Limited is a privately owned family company with a world-wide reputation for excellence in the design and manufacture of blast finishing, spray wash and ultrasonic cleaning equipment. Formed nearly 80 years ago, the company is registered to BS EN ISO 9001: 2008 and BS OHSAS 18001:2007 and its head office is located at Skipton, North Yorkshire, in the north of England. Guyson has four international subsidiary companies: Guyson Corporation of the USA, located in Saratoga Springs, New York State; Guyson SA, situated near Paris, France; Guyson Sdn Bhd in Penang, Malaysia; and Guyson CN, in Wuxi, Jiangsu Province, China.

Guyson International Limited

Snaygill Industrial Estate, Keighley Road,

SKIPTON, North Yorkshire, England BD23 2QR

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Guyson to Release Details of Powder Recovery System at TCT 2017 here

News-ID: 668442 • Views: …

More Releases from Guyson International Ltd

Extra-Large Blast Machine for Blast Etching Aerospace Rings

Guyson International, the UK's foremost industrial finishing equipment manufacturer, has installed a Guyson Euroblast® 2-metre PF (Pressure Fed) blast system into a division of a leading European aerospace company. The extra-large blast cabinet is used to deliver a uniform etched key surface on a range of machined circular aluminium rings prior to bonding.

After blast trails performed at the company's Skipton demonstration centre, a Euroblast 2-metre PF blast system (2.1…

Guyson Twin Spindle Blast Machine for Etching Tubular Components

Guyson International, the UK's leading manufacturer of industrial finishing equipment, has recently manufactured and installed into a UK manufacturing company an automated Multiblast RSB twin spindle blast system for externally blast etching various sizes of tubular components. This new blast system incorporates two rotating blast stations with matching top clamps, to hold the product securely, whilst two vertically traversing blast guns produce a uniform blast etch finish over the length…

Guyson Staff Clock-Up 180 Years!

At Guyson International's Skipton headquarters, Monday 15th August saw rain, much needed, and celebrations, much deserved. Employees from the company's blast and wash division gathered outside to congratulate seven employees who were awarded long service awards. And between them amassed a total of 180 years of service at Guyson, with one, Keith Miller celebrating 50 years of service.

In typical unpredictable UK weather, after so many days of bright hot sunshine,…

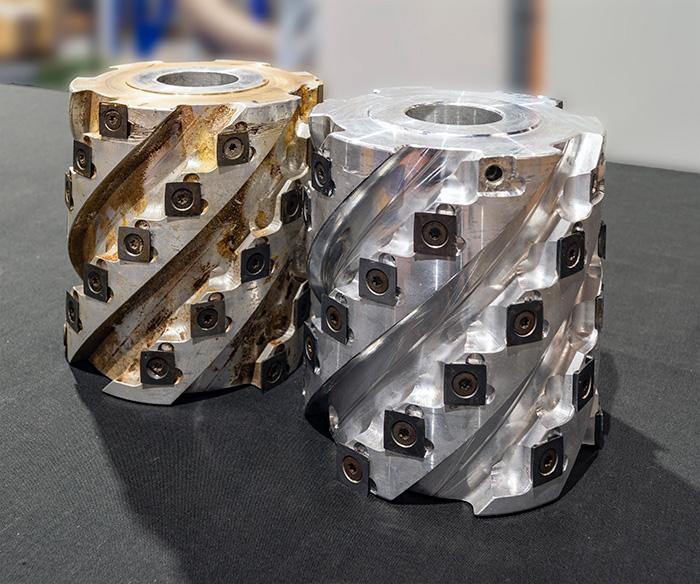

Guyson Equipment Cleans and Maintains Planing and Woodcutting Tools

Guyson International, one of the UK's leading manufacturers of industrial finishing equipment, recently delivered a KS450 ultrasonic cleaning tank and a Formula 1200 benchtop bead blast cabinet to RHW (R H Wilson (Lakes) Ltd.) of Kirkby Stephen, a leading timber importer and supplier, for cleaning and maintaining their wood cutting and planing tools.

The problem was how best to clean 'helical planer blocks' to remove a build-up of pitch, sap, resin…

More Releases for C600

Guyson to Launch New ATEX Blast Cabinet Systems at TCT

Industrial finishing equipment manufacturer Guyson International will be showcasing their new Euroblast® Ex range of blast systems at TCT 2018 – stand S44. Designed for use with potentially explosive powders and certified to the directive ATEX 2014/34/EU the systems are coded; ATEX II 2/3 D Ex h T135 °C Db/Dc.

Particularly relevant in Additive Manufacturing (AM) applications where the use of fine powders of materials…

Micro Turbine 2018 Market Global Key Country Analysis: Wilson Solarpower Corpora …

Micro Turbine Market Top Key Players:-

• Capstone Turbine Corporation

• FlexEnergy, Inc.

• Ansaldo Energia S.p.A

• Brayton Energy LLC.

• Eneftech Innovation SA

• Microturbine Technology BV

• Wilson Solarpower Corporation

• ICR Turbine Engine Corporation

Get Sample Copy of Report @ https://www.marketresearchfuture.com/sample_request/4099

Market Overview:-

Micro turbines are commonly utilized for the power generation solution due to its robust size, light weight, and advanced efficiency. The utilization of micro turbines outcomes in the minor electricity cost which increases the demand…

Guyson Supports the University of Bradford with Donated Blast Cabinet

Skipton based industrial finishing equipment manufacturer Guyson International, made initial contact with the University of Bradford during last year’s TCT + Personalize show, held at the NEC, which Guyson and University of Bradford regularly attends. Mr Mark Viner, Guyson’s Blast & Wash divisions Managing Director, visited the Universities show stand, and subsequent arrangements were made for further visits to the Polymer MNT laboratories at Bradford. During these visits common research…

New Guyson Blast Finishing Equipment to be Exhibited at TCT Show

Leading industrial finishing equipment manufacturer Guyson International will be exhibiting equipment from their blast finishing and ‘Kerry’ branded ultrasonic cleaning ranges at the forthcoming TCT + Personalize show to be held at the NEC, from the 28-29th September 2016. This exhibition covers all aspects of 3D printing, additive manufacturing (AM) and rapid prototyping and Guyson can be visited on Stand No. J26.

Showing for the first time at ‘TCT + Personalize’…

Swan-Matic Redesigns Trigger Spray Capping Machine

Automation Devices, Inc.’s (ADI) Swan-Matic Division has improved the C600 Rotary Trigger Spray Cap Tightener with a new, redesigned model. The updated C600 offers customers who are capping trigger spray bottles an advanced system with unique features unlike competitor models.

The C600, redesigned by Swan-Matic newcomer Sean Parker, provides predictable torque, ultimately ensuring accuracy of the cap being secured. “The C600 needed an outside perspective to determine how it…

Linux Kernel 3.x Support for all Perle Multimodem Cards

NASHVILLE, TN—April 16th, 2012— Perle Systems, a global provider of advanced serial to Ethernet and secure device networking solutions announced today Linux Kernel 3.x support for the full range of PCI-RAS Multimodem Cards. All drivers can be downloaded from Perle’s website.

“Perle Systems PCI-RAS Multimodem cards to provide an easy to administer dial-in/dial-out solution for remote workers and customers.” comments Julie McDaniel, Vice President Marketing, Perle Systems. She adds, “With…