Press release

Fourslide parts from Lee Spring – electrical contacts, clips, spring formed components

The fourslide process from Lee Spring delivers stamped and formed flat springs to custom designs and for extended runs of manufacturer standards. Fourslide manufactured parts find application throughout manufacturing across industries such as electronics, aerospace, automation, white goods, specialist vehicles, rail, building/construction, wherever a custom strip or wire fixing or fitting is required in high volume and to low cost. This includes flat springs, brackets, clips, flat terminals, or any stamped and formed metal components otherwise requiring custom tooling to produce intricate metal parts from flat strip material or from drawn or rolled wire.The fourslide process can reduce part cost, accelerate product delivery and streamline quality assurance with an integrated stamping and forming operation. Fourslide production has low to moderate tooling costs and produces accurate repeatable parts quickly and reliably.

The most commonly used materials with fourslide manufacturing are low-carbon or high-carbon cold rolled steel, type 300 and 400 stainless spring steels, copper alloys including beryllium-copper, bronze alloys including phosphor bronze.

The greatest advantage of the fourslide machine however is its ability to complete all of the actions required to produce a part from start to finish economically. It can handle certain parts that transfer or progressive dies cannot, since it can manipulate from four axes. Because this process requires less machinery, setups and handling, the cost of the finished part is reduced.

Lee Spring offer over 25,000 standard ex-stock same-day despatch springs and related spring components, as well as their highly experienced custom design service helping manufacturing industry grow.

Further information on Fourslide parts from Lee Spring can be found at: www.leespring.com/uk_quote_four-slide.asp or follow them on twitter - https://twitter.com/leespringuk.

Lee Spring is the UK supplier of choice for catalogued and custom springs, including compression springs, torsion springs, constant force springs, die springs, belleville spring washers, wave springs, extension springs, battery springs and numerous speciality springs. Materials include steel, stainless steel, cobalt/nickel alloy, bronze, brass, music wire and composite plastics.

In addition, Lee Spring offer extensive custom design and manufacture services for one-off/prototypes or ongoing production requirements.

Lee Spring Ltd

Latimer Road

Wokingham

Berkshire

RG41 2WA

Tel: 0118 978 1800

email: sales@leespring.co.uk

www.leespring.co.uk

Press contact: Christopher Petts

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Fourslide parts from Lee Spring – electrical contacts, clips, spring formed components here

News-ID: 636024 • Views: …

More Releases from Lee Spring Ltd

New website – New Online store – customers can now shop for Lee Spring parts …

Market leaders Lee Spring are delighted to provide their customers with the opportunity to buy online with full account management and basket purchasing facilities on their new easy to navigate website at www.leespring.co.uk – a fast ecommerce experience with highly efficient product search and CAD downloads.

Lee Spring offer over 25,000 stock spring designs on this site - ready to ship today with pricing and detailed specifications easy to view. These…

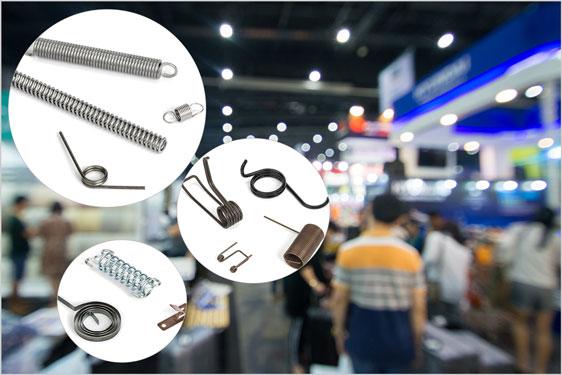

Lee Spring at Southern Manufacturing & Electronics Exhibition, Farnborough, 11-1 …

This year at Southern Manufacturing Exhibition, engineers and buyers seeking expertise in spring technology will be able to talk directly with the technical experts at Lee Spring. Lee Spring has recently expanded their UK manufacturing operations with the acquisition of Longcroft Engineering located in Lancashire between Manchester and Leeds. This acquisition provides Lee Spring with additional resources and capabilities to engineer and manufacturer a wider range of products here in…

Exotic alloys - Lee Spring explain what they are and when to use them

Materials with high alloy content, known as super alloys or exotic alloys, offer enhanced performance properties including excellent strength and durability, and resistance to oxidation, corrosion and deforming at high temperatures or under extreme pressure. Because of these properties, super alloys make the best spring materials for demanding working conditions, which can be encountered across various industry sectors, including the Automotive, Marine and Aerospace sectors as well as oil and…

REDUX™ Wave Springs from Lee Spring – an enabling technology

Lee Spring REDUX™ wave springs offer a way of performing a spring function in minimal spaces – even perhaps where no other spring could work effectively. Typically, REDUX wave springs occupy just 30-50% of the compressed height space of the conventional round wire springs, yet they offer more deflection with the same load specifications. This not only helps to save space in the applications but also reduces the production costs,…

More Releases for Fourslide

Battery Contacts Market Overview, Development History And Forecast To Shared In …

LOS ANGELES, United States: The global Battery Contacts market is broadly and deeply studied in the report with key focus on the competitive landscape, regional growth, market segmentation, and market dynamics. We have used latest primary and secondary research techniques for compiling this comprehensive research study. The report offers Porter's Five Forces analysis, PESTLE analysis, competitive analysis, manufacturing cost analysis, revenue and production analysis, and various other types of analysis…

Wire Forming Services Market Excellent Growth During 2022-2030 | Comprehensive S …

This Wire Forming Services market report examines a number of essential industry aspects that have a significant impact on the global Wire Forming Services industry, including a thorough examination of competitive advantage, recent advancements, regional industry environments, current Wire Forming Services market and production trends, dominant market challengers, and current end-user consumer behavior. The Wire Forming Services market study also examines the initially disclosed Wire Forming Services market size, customer…

Nose Wire for Face Masks Market Expected To Witness The Highest Growth 2024 | Ra …

Nose Wire for Face Masks Market Analysis to 2024 is a specialized and in-depth study of the Nose Wire for Face Masks industry with a focus on the market trend. The report aims to provide an overview of Nose Wire for Face Masks Market with detailed market segmentation by product/application and geography. Nose Wire for Face Masks Market report covers the present and past market scenarios, market development patterns, and…

Nose Wire for Face Masks Market Analysis by Emerging Growth Factors and Revenue …

The global Nose Wire for Face Mask market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global Nose Wire for Face Mask market. For instance, the market dynamics section digs deep into the drivers, restraints,…

Custom Stampings and customer standards from Lee Spring

Custom stampings are often at the heart of equipment – making connections, retaining components, operating elements within an OEM device. Each is normally required to fit a specific (custom) space or deliver a special operation and this is where Lee Spring can offer a high degree of expertise. Based on their long experience of producing standard and custom products, Lee Spring work from customer drawings with CAD (SolidWorks) to develop…

Lee Spring new sales/distribution centre opened in Germany

Of particular interest to Europe wide design/manufacturing companies will be the recently announced Lee Spring sales/distribution centre in Germany adding to the company’s existing distribution and engineering locations around the world.

Explained M.D. Dejan Unger: “We can offer customers across Europe expert distribution links with next day delivery to the majority of regions from our 23,000 plus ex-stock catalogue. Lee Spring Germany can supply direct to locations throughout Europe and…