Press release

Pinpoint Accuracy - Innovative Valve Technology with „QuickFix“ Nozzle Unit Boosts Performance of Solder Paste Dispensing Applications

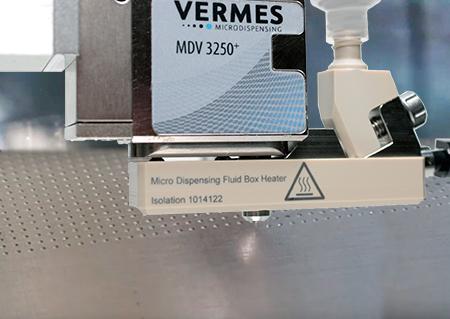

Munich, Germany, June 29th, 2017 – VERMES Microdispensing introduces the new MDFH-48-CH-TA (Micro Dispensing Fluid Box Heater) that provides excellent results for high and highest viscous media, especially in automated solder paste applications.In the course of continuing miniaturization, high-performance microdispensing systems that are capable of dispensing ever smaller amounts of media in a quick, accurate and contactless way are gaining more and importance. VERMES Microdispensing has been producing innovative, piezo-based microdispensing jetters for dispensing even critical media such as solder paste in a repeatable way for years. The VERMES MDS 3000 series is known for setting standards in precision, reproducibility and processing of a wide range of media.

By combining the MDS 3250+ system with the new fluid box heater MDFH-48-CH-TA VERMES Microdispensing has developed a further technical improvement that allows for process-safe, minimal solder paste quantities in a reliable and resource-saving way meeting most demanding customer requirements.

A key area for solder paste is the mounting of electronic components in the printed circuit boards assembly, for example for the application of electronic components on pads. This process requires the highest and very constant dispensing quality. A major part of the shortcomings in the production of printed circuit boards are caused by solder paste dispensing problems or unstable process conditions.

Equipped with a controller and a valve specially designed for sophisticated, highest viscous media the MDS 3250+ has become the system of choice for these applications. With its integrated fluid box heater and the optimized media guidance of the newly developed MDFH-48-CH-TA solder pastes of various types and classes can be dispensed for multiple applications.

The innovative „QuickFix” nozzle unit allows for a particularly effective and user friendly adjustment of tappet and nozzle. For many dispensing processes the very slim design adds a better control even for smallest components that are most difficult to access. Thanks to the compressed system design the media-carrying components can be cleaned easily and independently, which results in particularly low-maintenance demand.

In order to meet also extremely fine high-precision dispensing requirements VERMES Microdispensing has continued to optimize its valve systems so that they are now able to apply even smallest possible droplets with a small drop diameter at highest reproducibility.

„High-performance dispensing systems that are able to dispense ultra-small structures become more and more important for electronics manufacturing“, explains Jürgen Städtler, CEO of VERMES Microdispensing. „Our flexible jet system MDS 3250+ can be perfectly adapted to specific and challenging processes thanks to the system’s modular concept. Specially designed for solder paste and high and highest viscous media the MDS 3250 + solution delivers shortest dispensing cycles with high dynamics and frequencies.”

About us

Headquartered in Germany, VERMES Microdispensing revolutionized microdispensing technology with the introduction of its contact free piezo-based MDS 3000 series in 2001. Today, the company is a world leader in the design and manufacture of innovative microdispensing concepts and systems for adhesives, silicones, greases, solvents and other fluids.

VERMES high precision MDS 3000 valves support modern manufacturing processes across the globe, e.g. for automotive, pharmacology, smart phones, TV sets, lamps, wafers, automated manufacture of LEDs, MEMS components, RFID tags, LC displays and many other electronic devices.

Our systems enable our customers to achieve contact free dispensing of highly viscous media droplets in the micro and nano-liter range at theoretical frequencies of more than 3000 Hz; a rate that is unique in our industry.

VERMES Microdispensing employees are dedicated to providing the best technologies and services to its customers around the world with the ultimate aim of contributing to increased throughput, improved quality and lower production costs. More information about VERMES Microdispensing can be found at www.vermes.com.

VERMES Microdispensing is a trademark of VERMES Microdispensing GmbH in Germany and other countries.

Other names and brands may be claimed as the property of others.

Contact

Birgitt Harrow VERMES Microdispensing GmbH

Palnkamer Str. 18

83624 Otterfing, Germany Phone: +49 (0) 80 24-6-44-335

Fax: +49 (0) 80 24-6-44-19

pr@vermes.com

www.vermes.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Pinpoint Accuracy - Innovative Valve Technology with „QuickFix“ Nozzle Unit Boosts Performance of Solder Paste Dispensing Applications here

News-ID: 606538 • Views: …

More Releases from Vermes Microdispensing

VERMES Microdispensing registers subsidiary in India in response to the move of …

VERMES Microdispensing registers subsidiary in India in response to the move of major customers to this important market

Munich, Germany - May 10th, 2023 - VERMES Microdispensing today announced the opening of its own subsidiary in India, VERMES Microdispensing India Private Limited, based in the country's IT capital, Bengaluru.

VERMES Microdispensing CEO Juergen Staedtler has long held an interest in India, and now the company is setting up a spacious sales and…

VERMES Microdispensing forms subsidiary in Vietnam, a country with rapidly growi …

Munich, Germany - February 28th, 2023 - VERMES Microdispensing today announced that it has formed a new subsidiary, VERMES Microdispensing Vietnam Co., Ltd, located in Bac Ninh, marking the company's entry into the industrial hub of Northern Vietnam.

The area is home to several industrial parks with numerous manufacturers from the electronics, semiconductor, telecommunications, automotive and other industries.

The aim is to be closer to VERMES Microdispensing's customers in Vietnam and to…

VERMES Microdispensing opens new office in Midwest, USA

Columbus, Ohio - June 14th, 2022 - VERMES Microdispensing, a world leader in the design and manufacture of innovative microdispensing solutions, is proud to announce its opening of another office location in the United States of America.

The new office in Plain City, Ohio signifies VERMES Microdispensing's continued global growth and development.

With this step, the German company aims to bring its superior microdispensing system solutions and support services closer to the…

VERMES Microdispensing introduces its latest MDS 3050 series with unique feature …

Holzkirchen, Germany, October 5th, 2021 — VERMES Microdispensing, a world leader in the design and manufacture of innovative microdispensing concepts and systems introduces its MDS 3050 system, the newest member of the MDS 3000 series for low to medium viscosity dispensing.

The modern high precision, piezo-based jetters of the MDS 3050 series dispense minimal amounts in nano and sub-nano ranges and are suitable for a wide range of demanding industries…

More Releases for Micro

Micro Injection Molded Plastic Market worth $1,692 million by 2026 | Key players …

According to recent market research "Micro Injection Molded Plastic Market by Material Type (Liquid-Crystal Polymer (LCP), Polyether (PEEK), Polycarbonate (PC), Polyethylene (PE), Polyoxymethylene (POM)), Application and Region - Global Forecast to 2026", published by MarketsandMarkets, the micro injection molded plastic market is projected to reach USD 1,692 million by 2026, at a CAGR of 11.2% from USD 995 million in 2021.

Browse 193 market data Tables and 61 Figures spread through…

Micro Combined Heat & Power (Micro CHP) Market 2022 | Detailed Report

The Micro Combined Heat & Power (Micro CHP) research report combines vital data incorporating the competitive landscape, global, regional, and country-specific market size, market growth analysis, market share, recent developments, and market growth in segmentation. Furthermore, the Micro Combined Heat & Power (Micro CHP) research report offers information and thoughtful facts like share, revenue, historical data, and global market share. It also highlights vital aspects like opportunities, driving, product scope,…

Micro-Invasive Glaucoma Implants Micro-Invasive Glaucoma Implants

Global Micro-Invasive Glaucoma Implants Market Definition: Micro-invasive glaucoma implants is performed for the treatment of the open- angle glaucoma and is done through an ab- interno approach. It is very safe and provides faster recovery as compared to the traditional methods. They usually lower the intraocular by increasing the flow or reducing the production of the aqueous humor. Increasing cases of the glaucoma worldwide is the major factor fueling the…

Global Micro Electric Automotive (Micro EVs) Market Growth 2019-2024

Market Research Report Store offers a latest published report on Micro Electric Automotive (Micro EVs) Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report.

According to this study, over the next five years the Micro Electric Automotive (Micro EVs) market will register a 5.5% CAGR in terms of revenue, the global market size will reach US$ 9062.2 million by 2024, from…

Global Micro Welding Equipments Market- Growing Popularity and Emerging Trends i …

Welding is a fusion of the two workpieces of the surface to form one, is a precise, reliable, cost-effective and high tech method for joining material. Micro welding is a process that is specifically designed for the welding of small often delicate components. It is also known as precision welding. The process sets up the weld by depositing fine blobs of weld to the components to be fused. The process…

Comprehensive Analysis On Micro Welding Equipment Market 2019 : Pro-Fusion, OR L …

Up Market Research added a new Micro Welding Equipment Market research report for the period of 2019 – 2026. Report focuses on the major drivers and restraints providing analysis of the market share, segmentation, revenue forecasts and geographic regions of the market.

Get Sample Copy Of This Report @

https://www.upmarketresearch.com/home/requested_sample/108038

The report contains 112 pages which highly exhibit on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing…