Press release

UV/Visible light cure maskant for electronics – new from Intertronics

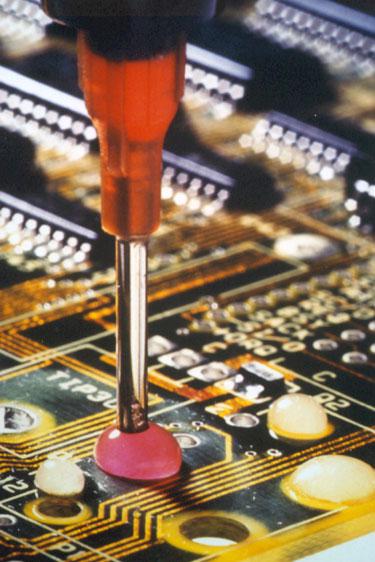

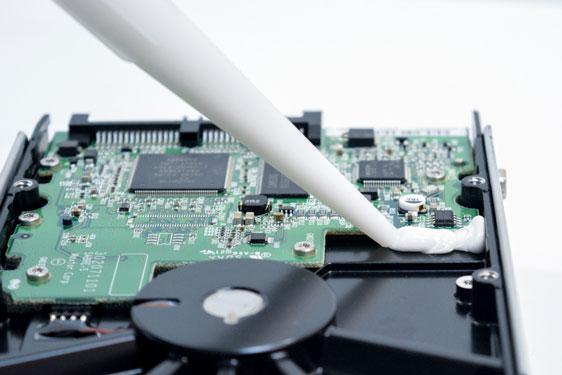

DYMAX Speedmask® 9-7001 from Intertronics offers significant time saving in assembly of electronics connectors and other board level components to PCBs. Once cured in seconds with UV/visible light, the (pink) maskant enables easy visual checks, while its low shrinkage rate ensures accurate reliable coverage.Speedmask® 9-7001 is designed for protecting connectors and board-level areas from both solvent based and light-curable conformal coatings. Cured masks withstand wave solder and solder reflow temperatures and are easily removed in one piece, saving time and eliminating the concern of ionic contamination or residue left behind by other masking methods. After removal, the residue free surface passes SIR testing, and is highly effective in maintaining the integrity of masked areas during process.

This halogen and silicone-free maskant is compatible with gold and copper connector pins. It very quickly cures upon exposure to light, and is designed to provide protection of connectors with no discoloration or corrosion. It is extremely thixotropic and is ideal for manual or automated dispensing onto boards or components that may be difficult to mask.

For further information please see www.intertronics.co.uk/speedmask-electronics or visit the Intertronics blog at www.adhere.uk.com – also see www.youtube.com/intertronicsadhere.

"adhere” from Intertronics provides quality adhesive solutions to high technology, high performance assembly industries, incorporating outstanding levels of technical support and customer service.

The adhere concept covers their range of adhesives, encapsulants, coatings, sealants and tapes as well as the associated dispensing, curing and surface preparation equipment and materials used in the manufacturing and assembly processes. Also their Opti-tec brand of adhesives.

Intertronics have been certified to ISO 9001:2008 standard demonstrating their commitment to customer service and quality in delivery. Certification proves that the Intertronics quality management system ensures consistency and a continuous improvement ethic, leading to high levels of performance and customer satisfaction.

Intertronics

Unit 17, Station Field Industrial Estate

Banbury Road

Kidlington

Oxfordshire

OX5 1JD

Tel: 01865 842842

email: info@intertronics.co.uk

www.intertronics.co.uk

blog: www.adhere.uk.com

Press contact: Peter Swanson

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release UV/Visible light cure maskant for electronics – new from Intertronics here

News-ID: 583063 • Views: …

More Releases from Intertronics

Tidy workplace and precise dispensing results from preeflow® eco-PEN450 for Fra …

Franklin Electric, a leading international manufacturer of water and fuel pumps, faced a difficult challenge when tasked with optimising dispensing processes at their Czech production site.

The objective was to reduce the waste of UV curing material during the application process. Dispensing equipment previously used by Franklin Electric had been very inaccurate, creating unnecessary waste, high material costs and additional cleaning efforts.

After completing preliminary tests, the team at Franklin Electric were…

WACKER ELASTOSIL® N9111 tin free silicone from Intertronics avoids conflicting …

WACKER ELASTOSIL® N9111 from Intertronics is a tin-free single part RTV silicone adhesive sealant, with a neutral cure chemistry, producing a non-corrosive seal that does not inhibit other materials such as platinum cure silicones. This, along with its UL94 V-0 rating, makes it a strong candidate for electronics manufacturing, especially for gap filling, component ruggedisation, and form-in-place gasketing. It is stocked in depth at Intertronics for next-day delivery.

Elastosil N9111 is…

preeflow precision dispensing system from Intertronics improves quality and redu …

The automobile manufacturing industry places high demands on suppliers with regard to process reliability, quality and efficiency. To meet these challenges, a preeflow customer had to optimise his application of a two-part sealant to make a form-in-place (FIP) gasket. In his previous process, the dispensed sealant bead exceeded the tolerance limits at the point where the gasket loop completed and the sealant overlapped itself. In addition, a key process variable…

New guidance from Intertronics – How to specify a dispensing robot to increase …

Automated application of adhesives, potting compounds or encapsulants, sealants, FIP gaskets, temporary masking, lubricants, or other liquids, fluids or pastes provides productivity benefits over manual application, including consistency, speed and accuracy. As selection of a dispensing robot is sometimes a daunting task, Intertronics, a specialist adhesives and dispensing company, has compiled a short piece of guidance on how to specify a dispensing robot. The full guidance can be found on…

More Releases for UV/Visible

Split Beam UV Visible Spectrophotometers Market 2021 | Detailed Report

The Split Beam UV Visible Spectrophotometers research report provides a detailed picture of the market by way of study, synthesis, and summation of data from multiple sources. The data thus presented is reliable, comprehensive and the result of extensive research both primary and secondary. The analysts have presented the various facets of the market with a particular focus on identifying the key industry influencers. Moreover, the data underlines the primary…

Global UV/Visible Spectroscopy Market Analysis by 2020-2025

Scope of the Report:

The global UV/Visible Spectroscopy market size is expected to gain market growth in the forecast period of 2020 to 2025, with a CAGR of 5.0%% in the forecast period of 2020 to 2025 and will expected to reach USD 253.2 million by 2025, from USD 208.1 million in 2019.

Market segmentation

UV/Visible Spectroscopy market is split by Type and by Application. For the period 2015-2025, the growth among segments…

New Electronics Adhesives that Cure with UV, Visible Light or Moisture

UK adhesives supplier Techsil has launched a range of new adhesive products with low ion content which cure with UV, visible light or moisture. Developed by manufacturers Panacol, these products were specially formulated for applications in the electronics and consumer electronics industry, where heat sensitive parts need to be assembled.

Vitralit® UD 8050 is a one-component acrylic adhesive, which can be used as an encapsulant to protect electronic components on…

UV/Visible Spectroscopy Market Size will Observe Substantial Growth by2026

(UV)Ultraviolet–visible spectroscopy, alternatively known as ultraviolet-visible spectrophotometry, refers to the absorption spectroscopy technique that measures the absorption of ultraviolet radiation due to its interaction with a sample. UV/visible spectroscopy utilizes light in the visible spectral ranges. The reflectance or absorption of UV radiation by a sample directly affects the color of the chemicals involved due to electronic transitions. Ultraviolet/visible spectroscopy is used extensively in analytical chemistry in order to determine…

UV / VISIBLE / LED CURABLE MULTI-SUBSTRATE (PLASTICS) GENERAL BONDER

Uni-Weld 1924

High Clarity, Cures Tack-Free, Medium Viscosity Bonder

Incure Uni-Weld 1924 UV / Visible / LED curable adhesive is an acid-free, multi-substrate medium viscosity bonder. High in clarity and cures tack-free, it is an excellent choice for applications requiring good bonding strength of 2,700 to 5,700 PSI on multiple substrates such as metals, glass, plastics, FR4 materials on a single application. Incure 1924 exhibits enhanced excellent moisture and temperature…

UV visible Spectrophotometer Market Size 2017 Shanghai Xin Mao Instrument

A market study based on the " UV visible Spectrophotometer Market " across the globe, recently added to the repository of Market Research, is titled ‘Global UV visible Spectrophotometer Market 2017’. The research report analyses the historical as well as present performance of the worldwide UV visible Spectrophotometer industry, and makes predictions on the future status of UV visible Spectrophotometer market on the basis of this analysis.

Get Free Sample Copy…