Press release

Industry 4.0 - 5 Things You Need to Know

The adoption process for Industry 4.0 has begun and the industry is already reaping the benefits: cost and risk reductions, performance improvements and enhanced flexibility. We share with you the 5 things you need to know about Industry 4.0 right now:Industry 4.0 – Explained

Industry 4.0 is a new approach to achieve results that weren’t possible a decade ago. Some industry experts are describing Industry 4.0 as the fourth industrial revolution, which is the move towards digitisation.

Industry 4.0 has three main benefits: cyber-physical systems such as sensors have the ability to collect data that can be used by manufacturers, systems can trawl through all of the data and form insights that can be acted upon quickly and lastly, the communications infrastructure backing the data up is secure enough to be used by heavy industries.

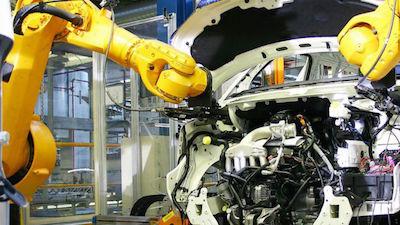

It is thought that smart factories will digest information and communication technology to help revolutionise the supply chain and production line. Machines using self-optimisation, self-configuration and artificial intelligence to complete tasks to deliver cost savings and a better quality of goods and services.

How Industry 4.0 developed

Industry 4.0 was first mentioned in 2013, in a high-tech strategy document by the German government which outlined a plan to fully computerise the manufacturing industry without the need for human involvement. The German government is investing £146 million to encourage research across academia, business and government to become the leading adopter of Industry 4.0.

IoT has a role to play

IoT will play a huge role in Industry 4.0 and will even underpin the development of it. The sheer volume of sensors and ‘things’ have a huge potential to feed information in to Industry 4.0. The two will work alongside one another to combine software, sensors, processors and communication technology.

Smart Factory Concept is Becoming a Reality

Industry 4.0 is fast becoming a possibility for low volume manufacturing as companies have the desire to manufacture custom products quickly and cost effectively. The CPS (cyber-physical system) is fundamental to this because it links all levels of the value chain in real-time, not only in the production environment but throughout all internal and external channels, from incoming orders, to design and customisation to delivery.

Levels of automation will continue to rise as the demand for reliability across the system strengthens. The volume of data required for Industry 4.0 will only increase and it is likely that EMC protection as well as speed and length limitations of copper-based cables will become more of an issue.

Industry Value

Accenture, a digital strategist company released a report in January 2015 which concluded that an industrial-scale version of the Internet of Things, or Industry 4.0, could add £9.54 trillion to the world economy by 2030 and the UK alone could benefit by up to £352 billion.

Cisco has reported that UK start ups have a massive chance to benefit by streamlining processes and thinks that the industrial internet will benefit by £100 billion.

Siemens, who already has a smart factory in Germany believe that the global market for industrial automation will post turnover of £134 billion by 2017.

The enormous value of the industry is down to the demand for higher productivity and cost reductions from using real-time data. This is just the beginning for future technologies such as 5G which will have a large effect on optimum frequency.

GD Rectifiers provides solutions for various automation applications and can supply both standard and bespoke offerings for all automotive environments.

For further information on automation solutions please contact our office: 01444 243 452 / enquiries@gdrectifiers.co.uk

www.gdrectifiers.co.uk

GD Rectifiers is a Global Manufacturer and Distributor of products, services and solutions to commercial and industrial users of power electronic components.

Established in 1964, GD Rectifiers has over 50 years of extensive experience across a large range of markets, specialising in new and current technologies for industrial power control applications. An extensive product offering has built GD Rectifiers exceptional reputation as the go-to power specialist with innovative experience across: Aviation, Automotive, Rail, Medical, Industrial and Electronics markets.

GD Rectifiers are an ISO 9001:2008 registered company that design and develop bespoke power semiconductor assemblies to control voltage, current and frequency for international industrial markets.

GD Rectifiers, Bentley House, 2 William Way,

Burgess Hill, West Sussex, RH15 9AG

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Industry 4.0 - 5 Things You Need to Know here

News-ID: 496739 • Views: …

More Releases from GD Rectifiers

GD Rectifiers Becomes a Distributor for ANYSOLAR

ANYSOLAR was founded in 2009 and is located in Yongin, Republic of Korea. ANYSOLAR has extensive experience in the solar industry and has previously produced high quality solar modules for IXYS: A Littelfuse brand, building a global solar module market for more than a decade.

In June 2020, IXYS sold the IXOLAR solar division to ANYSOLAR who acquired the business and customers from IXYS. IXOLAR now continues to attract new…

CNC Machining by GD Rectifiers

CNC Machining, also known as Computer Numerical Control machining is a cost effective way to increase efficiency in the workplace. In recent years, CNC machining has become an extremely popular manufacturing asset, for its intricate and complex capabilities designed for aerospace, marine, automotive and medical industries.

GD Rectifiers operates a fast and versatile CNC machine shop, offering customers the shortest lead times, competitive pricing and single source benefits. GD Rectifiers uses…

Custom Heatsinks for Optimum Thermal Management by GD Rectifiers

GD Rectifiers' customised heatsinks suit applications where standard products don’t meet the design brief, such as specific thermal performance or insufficient space requirements. GD Rectifiers offer a large range of customisations including: surface finish, drilling patterns, tapping, milling, length and shapes, with a choice of anodised colours or bare finishes.

GD Rectifiers can provide pre-applied thermal interface material, easing production processing and material management.

GD Rectifiers’ Managing Director, Paul Bentley explains:

“It is…

GD Rectifiers looks ahead to 2021

GD Rectifiers’ Managing Director, Paul Bentley reflects on 2020 and how Covid-19 has impacted the power electronics supply chain and discusses what the industry has to look forward to in 2021.

1) What significant changes and developments have you seen this year?

Earlier this year in March, during the first national lockdown we saw component sales soar as the country came together to respond to the urgent demand for ventilators…

More Releases for Industry

Hydro Lubricants Market Size, Analysis, and Forecast Report 2018 to 2026(By Indu …

The rising demand for hydro lubricants from manufacturing sector is also multiplying at a faster rate, on the back of their competency in upgrading the service-life of machinery. The hydro lubricants market is primarily driven on account of its low-friction attributes, which makes it highly likely to outshine the synthetic variants. Moreover, the demand for hydro lubricants for machinery assemblies is on the rise, as they facilitate in minimizing…

Hydro Lubricants Market Insights, Trends & Future Development Status Recorded du …

The rising demand for hydro lubricants from manufacturing sector is also multiplying at a faster rate, on the back of their competency in upgrading the service-life of machinery. The hydro lubricants market is primarily driven on account of its low-friction attributes, which makes it highly likely to outshine the synthetic variants. Moreover, the demand for hydro lubricants for machinery assemblies is on the rise, as they facilitate in minimizing…

Global Pyrite Market 2019 | Applications: Jewelry Industry, Sulfur Compounds Ind …

The major factor driving the pyrite market is the rising demand of jewelry and sulfur compounds market. This report researches the worldwide Pyrite market size (value, capacity, production, and consumption) in key regions like North America, Europe, Asia Pacific (China, Japan) and other regions. This study categorizes the global Pyrite breakdown data by manufacturers, region, type, and application, also analyzes the market status, market share, growth rate, future trends, market…

Big Bag Connection System Market Segmented By technology Automatic, Semi-Automat …

Global Big Bag Connection System Market: An Overview

The key advancement in automation encourages manufacturers to adopt smart systems to increase productivity and to facilitate timely production. Owing to the perception of consumers as well as manufacturers regarding health and hygiene of product, the big bag connection system market is anticipated to propel during the forecast period. Big bag connection system ensure dust -free docking of big bags and provide flexibility…

Global Nutraceuticals Market By Application | Food Industry, Ink Industry, Medic …

Researchmoz added Most up-to-date research on "Global Nutraceuticals Market By Application | Food Industry, Ink Industry, Medicine Industry, Electronic Industry and Paint Industry" to its huge collection of research reports.

This report studies Nutraceuticals in Global market, especially in North America, China, Europe, Southeast Asia, Japan and India, with production, revenue, consumption, import and export in these regions, from 2012 to 2016, and forecast to 2022.

This report focuses on top manufacturers…

Europe Plastic Pallet Market Size, Shares, Forecast Report 2016 : Food Industry, …

This report studies sales (consumption) of Plastic Pallet in Europe market, especially in Germany, UK, France, Russia, Italy, Benelux and Spain, focuses on top players in these countries, with sales, price, revenue and market share for each player in these Countries, covering

ShangHai Pallet Plastic Industry Co., Ltd.

Shanghai Lika Plastic Manufacturing Co., Ltd.

Guangzhou Plastic Industrial Corporation Ltd

Shandong Liyang Plastic Molding Co.,Ltd

Xinding Plastic

ZheJiang Primacy Plastic Industry Co., Ltd

Shanghai Qinghao Plastic Pallet Manufacture…