Press release

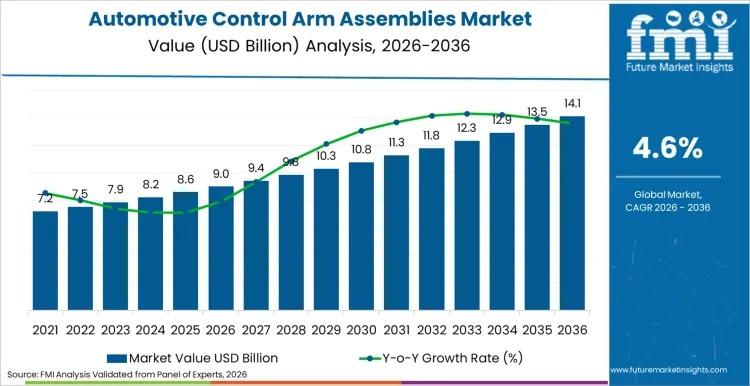

Automotive Control Arm Assemblies Market Market Value Analysis

The global automotive control arm assemblies market is projected to grow at a CAGR of 4.6% between 2026 and 2036, increasing from USD 9.0 billion to USD 13.6 billion. This steady expansion reflects the structural transformation underway in global suspension systems, where manufacturers are transitioning from conventional stamped steel designs toward multi-material engineered assemblies that improve vehicle handling, ride comfort, and structural durability.Growth is not merely volume-driven; it is innovation-led. Automotive OEMs are integrating advanced geometry designs, optimized load distribution, and enhanced mounting architectures to meet evolving vehicle performance benchmarks. As vehicles become heavier due to electrification and safety enhancements, suspension components such as control arm assemblies are becoming more critical in maintaining dynamic stability and operational efficiency.

Get Access of Report Sample

https://www.futuremarketinsights.com/reports/sample/rep-gb-31939

Research Methodology and Analytical Framework

FMI's projection is based on a bottom-up automotive component revenue model, incorporating vehicle production forecasts, raw material price assessments, performance benchmarking, and supplier capacity evaluations. This methodology ensures that demand estimation reflects real-world manufacturing trends and technology adoption curves across global automotive ecosystems.

Material innovation tracking and regulatory mapping further strengthen forecasting accuracy, particularly as suspension components face stricter durability and crashworthiness compliance requirements.

Market Evolution and Technology Transition

The automotive control arm assemblies market is evolving from standardized stamped components to precision-engineered, multi-material systems integrating steel, aluminum, forged alloys, and composite technologies. This shift aligns with OEM strategies focused on:

Reducing unsprung weight

Improving strength-to-weight ratios

Extending service life

Enhancing corrosion resistance

Advanced metallurgical treatments and automated manufacturing processes are enabling optimized structural geometry, ensuring improved load-bearing capabilities without compromising cost efficiency.

What is Driving the Demand for Automotive Control Arm Assemblies?

1. Rising Demand for Superior Vehicle Dynamics

Modern vehicles are increasingly designed around performance optimization, ride comfort, and enhanced handling precision. Control arm assemblies directly influence wheel alignment, suspension articulation, and steering stability. As consumers demand smoother driving experiences and manufacturers pursue premium positioning, the need for high-performance suspension components continues to rise.

Electric vehicles (EVs), in particular, amplify this requirement. Battery packs increase overall vehicle weight, requiring stronger yet lighter suspension assemblies to maintain stability and energy efficiency.

2. Regulatory Compliance and Safety Standards

Updated safety regulations, including enhanced crashworthiness benchmarks and durability mandates from global authorities such as IIHS and NHTSA, are accelerating adoption of advanced suspension systems. Control arm assemblies must now meet stricter fatigue resistance, corrosion testing, and impact performance requirements.

Manufacturers are integrating compliance-driven design innovations without sacrificing performance or manufacturability, reinforcing sustained market demand.

3. Electrification and Lightweight Engineering

The global EV transition is fundamentally reshaping suspension architecture. Lightweight materials such as aluminum and composites are gaining traction to offset battery weight and improve driving range.

Control arms manufactured with optimized metallurgy and composite integration offer:

Reduced vehicle mass

Improved energy efficiency

Lower lifecycle maintenance costs

Enhanced handling precision

This electrification-driven demand is a structural growth driver extending beyond traditional passenger vehicle segments.

How is the Automotive Control Arm Assemblies Market Segmented?

By Material Type

Steel (64.3% Market Share)

Steel remains dominant due to cost efficiency, durability, and high load-bearing capacity. Its adaptability across passenger cars, commercial vehicles, and performance segments ensures continued relevance. Steel assemblies provide design flexibility and are highly compatible with mass production systems.

Aluminum

Aluminum is gaining momentum, especially in EV and performance vehicles. Its lightweight characteristics reduce unsprung mass, improving ride quality and fuel economy. Though more expensive, aluminum delivers performance advantages that justify adoption in premium and electrified platforms.

Composite Materials

Composites are emerging in niche applications requiring corrosion resistance and extreme weight reduction. While currently limited by higher production costs, technological advancements may expand their adoption in high-performance and electric segments.

By Vehicle Type

Passenger Cars (42.1% Market Share)

Passenger vehicles dominate due to high production volumes and growing demand for ride comfort and handling optimization. Advanced suspension geometry is critical in ensuring smooth operation across varied driving conditions.

Commercial Vehicles

Heavy-duty applications require reinforced control arm assemblies capable of sustaining high load stress and extended operational cycles. Durability and reliability are key purchasing criteria in this segment.

Electric and Performance Vehicles

These segments emphasize lightweight engineering and precision dynamics. Manufacturers are investing in specialized testing protocols and validation processes to ensure regulatory compliance and durability performance.

How Is Technological Evolution Reshaping Automotive Control Arm Assemblies?

1. Integration of Precision Ball Joints and Bushings

Modern assemblies now integrate enhanced ball joint systems and advanced bushing technologies to reduce vibration and improve suspension responsiveness. This increases ride comfort while maintaining structural rigidity.

2. Automated Production and Smart Manufacturing

Automation in forging, stamping, and machining processes ensures consistent dimensional accuracy and reduced defect rates. Smart production systems enhance scalability while maintaining cost competitiveness.

3. Multi-Material Platform Engineering

Manufacturers are combining steel cores with aluminum extensions or composite reinforcements to optimize weight distribution and load performance. These hybrid platforms represent the next phase of suspension innovation.

Exhaustive Market Report: A Complete Study

https://www.futuremarketinsights.com/reports/automotive-control-arm-assemblies-market

How Is the Automotive Control Arm Assemblies Market Evolving Globally?

China - Manufacturing Scale Advantage (5.9% CAGR)

China's automotive expansion and EV dominance are fueling control arm demand. Automated production integration and high-volume manufacturing capabilities strengthen domestic supply chains while enhancing export potential.

India - Quality Standard Upgradation (5.5% CAGR)

India's automotive ecosystem is transitioning toward premium component standards to compete globally. Increasing middle-class vehicle ownership and OEM localization are boosting demand for durable, high-quality suspension assemblies.

Germany - Engineering Precision Leadership (5.1% CAGR)

Germany's focus on premium automotive engineering drives adoption of advanced suspension technologies. High-performance EVs and luxury vehicles require precision-engineered assemblies aligned with strict EU regulatory standards.

USA - Innovation and Specialized Applications (4.2% CAGR)

The U.S. market emphasizes performance vehicles and regulatory compliance. Advanced material innovation and integration capabilities position manufacturers to serve both domestic and export markets effectively.

UK - Electrification Acceleration (3.7% CAGR)

The UK's Zero Emission Vehicle Mandate is accelerating lightweight suspension adoption. Aluminum and composite control arms are gaining traction in electric and performance vehicles to balance weight and regulatory compliance.

Competitive Landscape and Strategic Positioning

Major industry players such as:

• ZF Friedrichshafen AG

• Magna International Inc

• Tenneco Inc

• Moog Inc

• TRW Automotive Holdings

• ThyssenKrupp AG

• Continental AG

• Benteler International AG

• Schaeffler Group

Similar Industry Reports

Automotive Suspension Control Arms Market

https://www.futuremarketinsights.com/reports/automotive-suspension-control-arms-market

Automotive Control Panel Market

https://www.futuremarketinsights.com/reports/automotive-control-panel-market

Automotive Control Cables Market

https://www.futuremarketinsights.com/reports/automotive-control-cable-market

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-845-579-5705

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Automotive Control Arm Assemblies Market Market Value Analysis here

News-ID: 4399075 • Views: …

More Releases from Future Market Insights

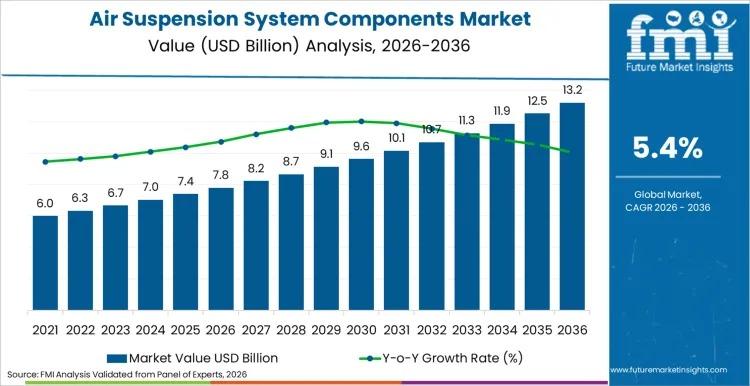

Global Air Suspension System Components Market to Reach USD 13.2 Billion by 2036 …

The global air suspension system components market is projected to expand from USD 7.8 billion in 2026 to USD 13.2 billion by 2036, advancing at a CAGR of 5.4%, according to the latest industry analysis. This sustained growth reflects the accelerating transition from traditional mechanical suspension systems to advanced electronically controlled air suspension technologies designed to enhance ride comfort, optimize load management, and improve vehicle stability across passenger and commercial…

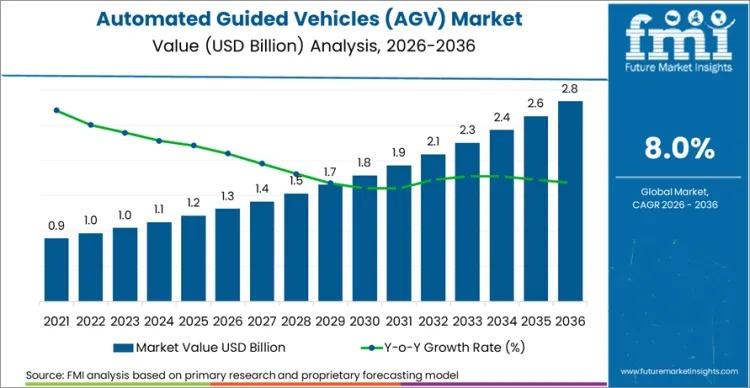

Global Automated Guided Vehicles Market to Reach USD 2.84 Billion by 2036 as Clo …

The global Automated Guided Vehicles (AGV) market is entering a decisive expansion phase, projected to grow from USD 1,314.1 million in 2026 to USD 2,837.2 million by 2036, reflecting a robust CAGR of 8.0%. The market's structural acceleration is being driven by sustained warehouse automation demand, persistent labor shortages, and the rapid scaling of e-commerce fulfillment networks worldwide.

According to Future Market Insights (FMI), the growth trajectory is firmly anchored in…

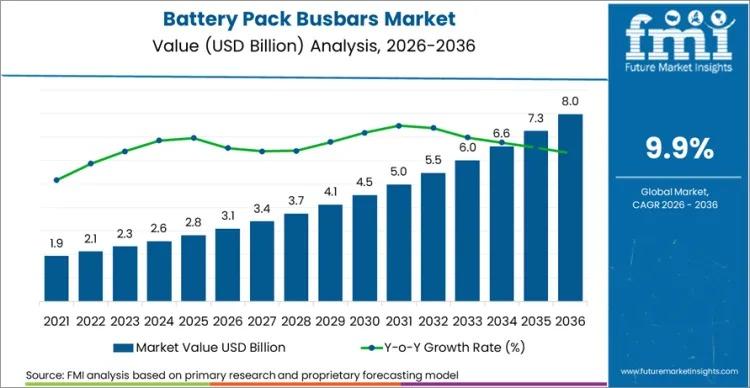

Global Battery Pack Busbars Market to Reach USD 8.0 Billion by 2036 as High-Volt …

The global battery pack busbars market is undergoing a structural transformation, with total revenue projected to increase from USD 3.1 billion in 2026 to USD 8.0 billion by 2036, advancing at a robust CAGR of 9.9% over the forecast period. This expansion reflects the rapid evolution of high-voltage battery systems across electric vehicles (EVs), stationary energy storage, and industrial electrification, where busbars are transitioning from basic conductive components into integrated,…

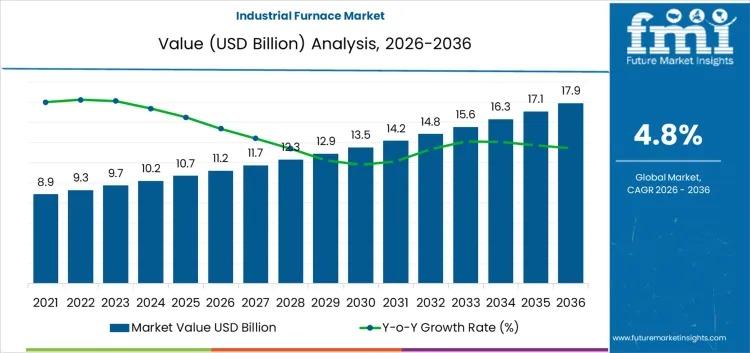

Industrial Furnace Market to Reach USD 17.9 Billion by 2036 as Energy-Efficient …

The global industrial furnace market is projected to grow from USD 11.2 billion in 2026 to USD 17.9 billion by 2036, expanding at a compound annual growth rate (CAGR) of 4.80%, according to the latest industry analysis. This steady expansion reflects sustained global demand for high-performance thermal processing systems as industries accelerate modernization, adopt energy-efficient infrastructure, and integrate advanced automation technologies to enhance production efficiency and reduce operating costs.

Industrial furnaces…

More Releases for Control

Top distributors of Access Control & Entrance Control Solutions

FOR IMMEDIATE RELEASE

CDN Technology Delivers Advanced Security and Workforce Solutions to Leading Enterprises in India

India - CDN Technology, (https://www.cdntechnology.co/) a trusted provider of access control, attendance, and security solutions, is strengthening India's enterprise and institutional security infrastructure with cutting-edge products and robust service delivery.

Specialising in biometric and AI-based face recognition attendance machines, access control systems, boom barriers (https://www.cdntechnology.co/products/boom-barrier), flap barriers, turnstiles, door frame metal detectors, and baggage scanners, CDN Technology…

Taking Control: Automotive Seat Control Modules Market Innovations

According to the recent findings by Persistence Market Research, sales of automotive seat control modules are anticipated to reach a value of US$ 8.95 Billion in 2022 with consistent long-term projections for the market. According to the report, the market will expand at 5.3% CAGR from 2022 to 2032. Automotive seat control modules are seeing increasing sales as customers demand more comfortable seats and various automobile interior accessories.

Integrated systems that…

Insect pest control Market Demand, Overview, Size, Trend, and Cleankill Pest Con …

Global Insect pest control report from Global Insight Services is the single authoritative source of intelligence on Insect pest control market. The report will provide you with analysis of impact of latest market disruptions such as Russia-Ukraine war and Covid-19 on the market. Report provides qualitative analysis of the market using various frameworks such as Porters' and PESTLE analysis. Report includes in-depth segmentation and market size data by categories, product…

Global Control Valves Market | Control Valves Industry | Covid-19 Impact Global …

Control valves refer to valves used in process industries to regulate process variables, such as flow, pressure, temperature, and fluid level in process industries including water management, chemicals, oil & gas, power generation, pharmaceuticals, automotive, mining, and food & beverages. These valves play a vital role in mounting efficiency, safety, and profitability of these process industries. Moreover, manufacturers of control valves are continually engaged in research & development (R&D) activities…

Turbine Control System Market Report 2018: Segmentation by Component (Sensors, H …

Global Turbine Control System market research report provides company profile for ABB (Switzerland), Siemens (Germany), Honeywell (US), Emerson (US), GE (US) and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the year 2018 to 2025, etc. The report also provides…

Global Acoustic Control System Market 2017 Acoustic Control, Oceaneering Interna …

Global Acoustic Control System sales will reach about 1011 billion USD in 2017 from 875 billion USD in 2012 all around the world, with the CAGR of 2.62%. The Leading growing markets are China, Southeast Asia, etc. USA, EU, Oceania, India, etc. is the mature market with low growth rate.

Global Acoustic Control System Market Size, Status and Forecast 2022 provides Market information about Manufacturers, Countries, Type and Application.This Acoustic Control…